Amorphous cutting tool coating used for dry machining of aluminum alloy and preparation method of the coating

A technology for aluminum alloys and cutting tools, which is applied in the field of coating and preparation of amorphous cutting tools for aluminum alloy dry processing, and can solve the problems of high preparation temperature and strict temperature resistance requirements of cutting tool materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In order to obtain the amorphous tool coating for aluminum alloy dry machining described in the application, the application also provides a preparation method for the amorphous tool coating for aluminum alloy dry machining, comprising the following steps:

[0050] A bonding layer is deposited on the surface of the workpiece to be plated after pretreatment by magnetron sputtering;

[0051] Depositing a transition layer on the surface of the bonding layer by magnetron sputtering under reactive vapor deposition conditions;

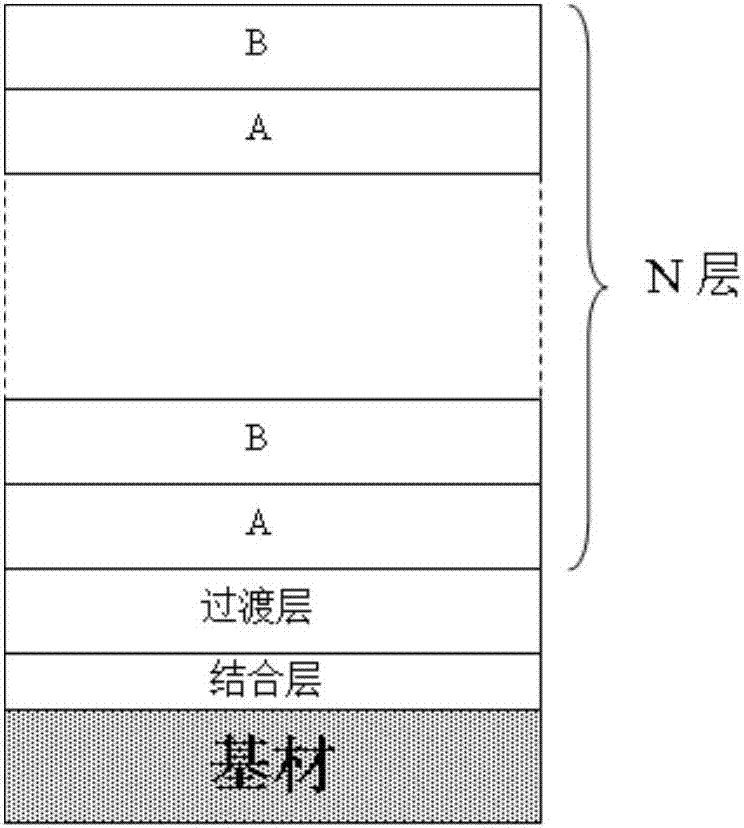

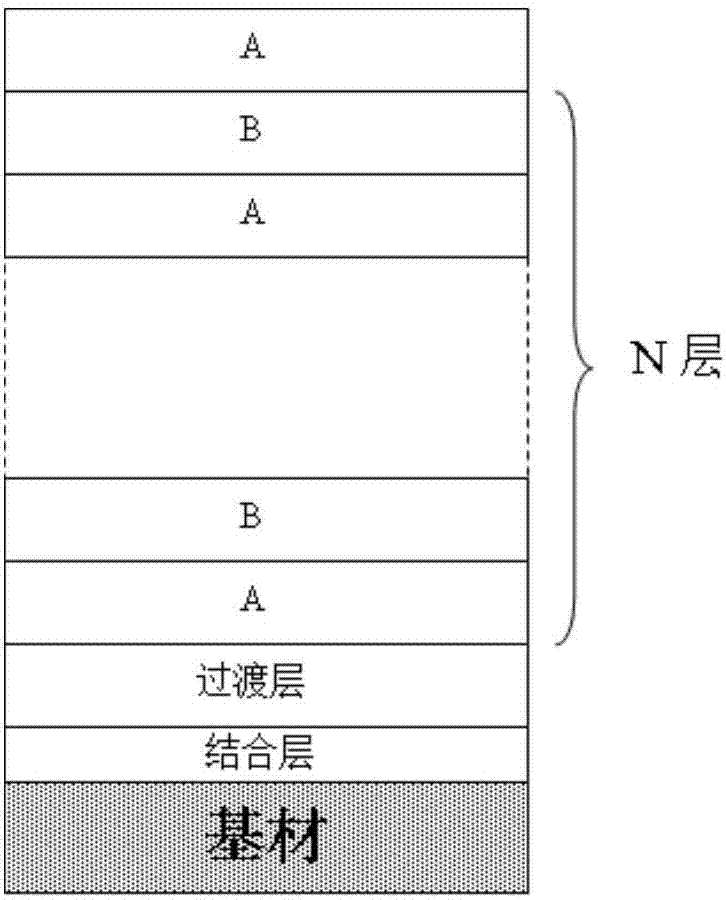

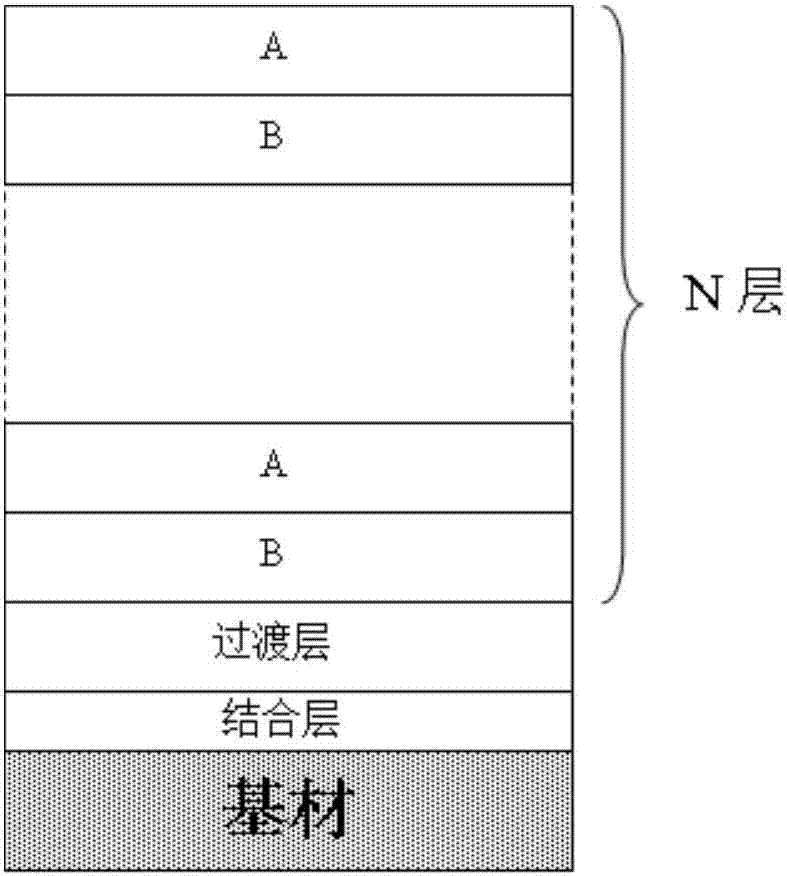

[0052] A functional film layer is deposited on the surface of the transition layer, and the functional film layer is composed of alternately stacked A layers and B layers, the number of layers of the A layer is ≥1, the number of layers of the B layer is ≥1, and the The layer A is obtained by magnetron sputtering, and the layer B is obtained by applying a bias voltage to carbon ions or carbon-hydrogen ions.

[0053] In the above-mentioned process of p...

Embodiment 1

[0076] Embodiment 1 Pretreatment of workpiece to be plated, preparation of bonding layer and transition layer

[0077] (1) Degrease the workpiece to be plated-ordinary tool, degrease with lye, rinse with pure water, dehydrate and dry with hot air (120°C) to remove rust, oil stains and other stains on the workpiece;

[0078] (2) Put the workpiece to be plated through the process (1) into the vacuum chamber;

[0079](3) Vacuumize the vacuum chamber and heat the vacuum chamber at the same time, keeping the heating temperature at 150°C; when the vacuum degree of the vacuum chamber is better than 5×10 -4 After Pa, adjust the temperature of the vacuum chamber and stabilize it at 120°C;

[0080] (4) The vacuum chamber is fed with argon gas, and the anode layer ion source is operated in the high voltage and low current discharge mode to generate argon ions; at the same time, the bias power supply is turned on, and the bias value is set to -1500V, and the workpiece to be plated is sub...

Embodiment 2

[0082] Example 2 Preparation of Amorphous Tool Coatings for Dry Machining of High-Strength Aluminum Alloys Using Magnetron Sputtering Deposition Method

[0083] (1)~(5) the pretreatment of the workpiece to be plated, the preparation of the bonding layer and the preparation of the transition layer are the same as in Example 1;

[0084] (6) Under argon atmosphere, magnetron sputtering chromium target and graphite target at the same time, the power supply of the sputtering target is DC power supply, and the power density of the sputtering target is less than 8W / cm 2 ;During the coating process, the vacuum degree is 0.5Pa, and the temperature of the vacuum chamber is adjusted and stabilized at 120°C; a bias voltage of -100V is applied to the workpiece to deposit and coat the a-CrC / a-C amorphous sub-film layer, and the bias power supply is a DC power supply;

[0085] (7) Repeat step (6) of this embodiment, wherein, only magnetron sputtering graphite target material is carried out, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com