Ceramic fiber sealing pad plate and preparation method thereof

A technology of sealing backing plate and ceramic fiber, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of high price, risk of long-term temperature resistance, poor high temperature resistance and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The raw materials for the preparation of the ceramic fiber sealing backing plate provided by the present invention include anorthite, and the anorthite is preferably anorthite powder. The anorthite is a chemical formula of CaO·Al 2 o 3 2SiO2 2 high temperature synthetic minerals. The amount of the anorthite added to 100 parts by mass of the ceramic fiber sealing backing plate is 20-50 parts by mass, preferably 25-45 parts by mass, more preferably 20-40 parts by mass.

[0082] The raw materials for the preparation of the ceramic fiber sealing backing plate provided by the present invention include cordierite, and the cordierite is preferably cordierite powder. The cordierite is a chemical formula of 2MgO·2Al 2 o 3 ·5SiO2 2 high temperature synthetic minerals. The amount of cordierite added to 100 parts by mass of the ceramic fiber sealing backing plate is 20-40 parts by mass, preferably 25-35 parts by mass, more preferably 27-32 parts by mass.

[0083] The raw ma...

Embodiment 1

[0150] Add 60kg standard aluminum silicate fiber cotton, 120kg2.5wt% log pulp, 115kg anorthite powder, 80kg cordierite powder, 32kg muscovite, 6kg silicon carbide whiskers and 30kg nitrile latex (solid content 15kg) The pulping machine is used for pulping, and the fiber length after pulping is 3-5mm, and then added with 3Kg white carbon black, 0.6Kg zinc oxide, 0.6kg sulfur, 0.45kg accelerator PZ, 0.3kg anti-aging agent D for pre-grinding One portion of the slurry, and then add an appropriate proportion of water to keep the mass concentration of the slurry at 2.8%, and then use fourdrinier drawing forming equipment for molding, dehydration, drying, and calendering at 130°C on a paper machine to make high-temperature resistant Grind the ceramic fiber gasket.

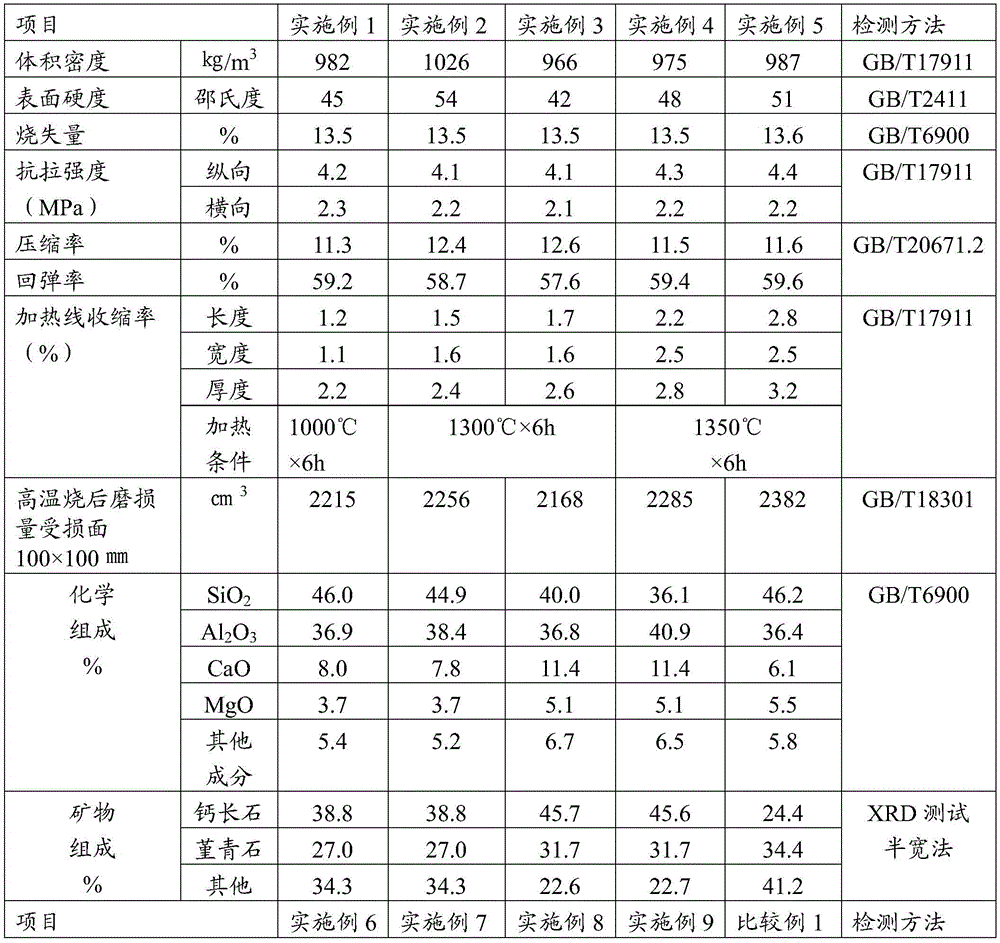

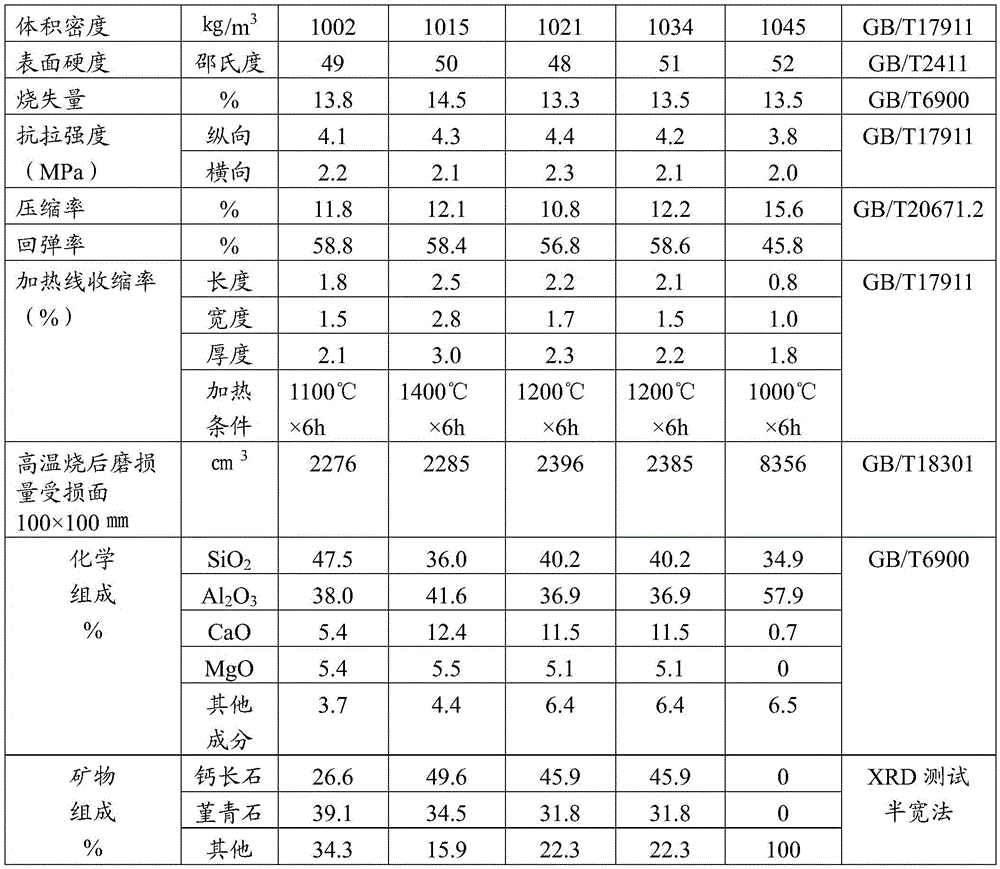

[0151] The obtained ceramic fiber sealing backing plate was subjected to a performance test, and the results are shown in Table 2. Table 2 shows the performance test results of the ceramic fiber sealing backing plate.

Embodiment 2

[0153] In Example 2, the standard aluminum silicate fiber cotton was replaced by high-alumina aluminum silicate fiber cotton, and the rest of the components remained unchanged. The same method as in Example 1 was used to prepare a high-temperature wear-resistant ceramic fiber sealing backing plate.

[0154] The obtained ceramic fiber sealing backing plate was subjected to a performance test, and the results are shown in Table 2. Table 2 shows the performance test results of the ceramic fiber sealing backing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long-term use temperature | aaaaa | aaaaa |

| Maximum operating temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com