Method for prolonging service life of hot forging die

A technology of die life and hot forging, applied in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. Hardness, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

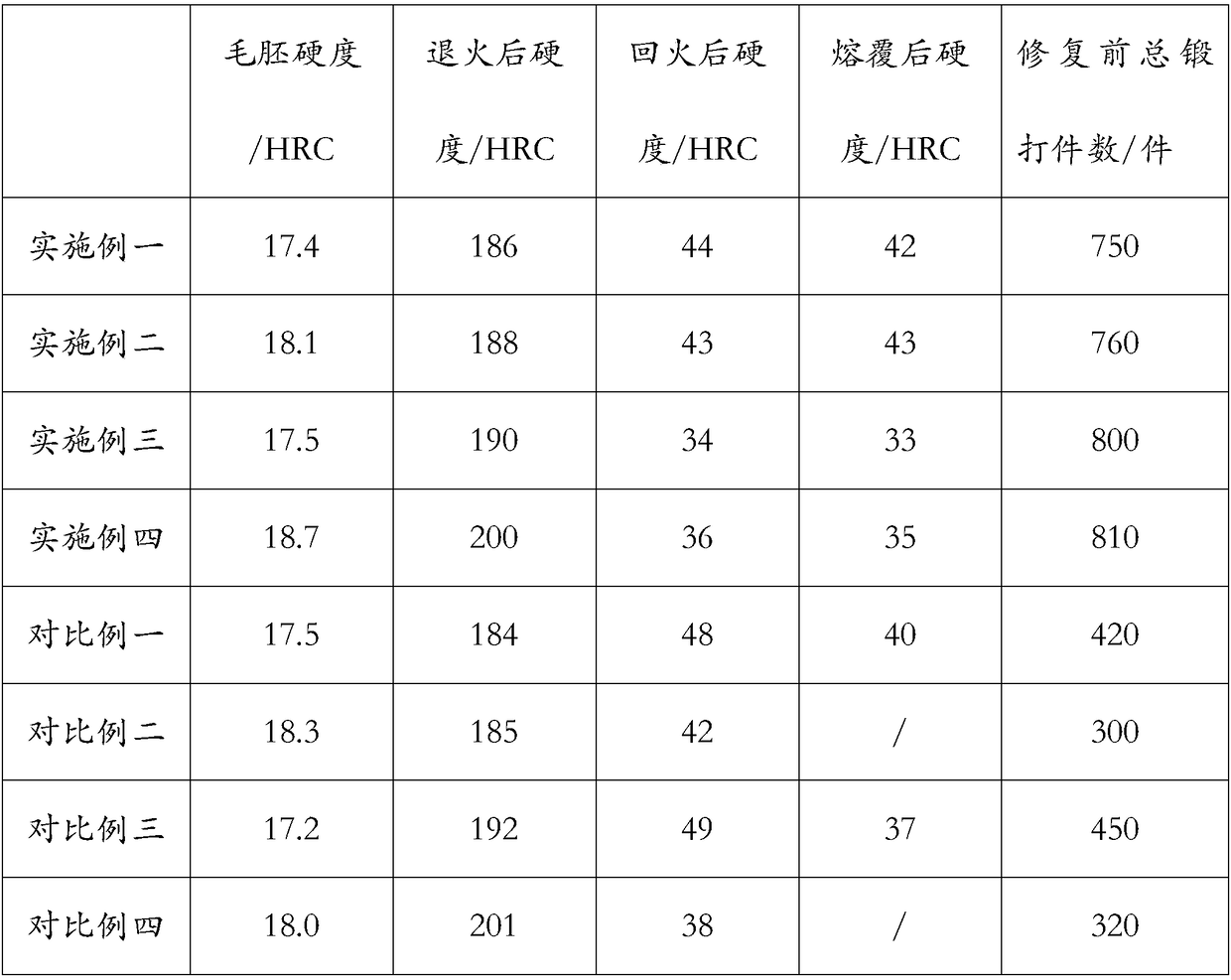

Examples

Embodiment 1

[0033] In this embodiment, a small and medium-sized mold with a hot forging material of 5CrNiMo and a height of 260 mm is used as an example, and the mold undergoes forging, annealing, quenching, tempering and laser cladding in sequence.

[0034] A method for improving the service life of a hot forging die, specifically comprising the following steps:

[0035] S1: Forging, the initial forging temperature is 1200°C, the final forging temperature is 800°C, and the air cooling is 30s.

[0036] S2: annealing, heating the mold to 800°C, holding it for 4 hours, cooling to 370°C, out of the furnace, air-cooling to room temperature, sampling 4 points, and performing step S3 when the hardness is 185HB-210HB, otherwise, repeating step S2.

[0037] S3: Quenching, heating the mold, the heating process adopts the gradient heating method, the heating rate is 180 ℃ / h, and when the temperature is 350 ℃, 540 ℃, 720 ℃, hold for 1 hour, heat to 850 ℃, hold for 5 hours, and release, Cool to 750°...

Embodiment 2

[0045] In this embodiment, a small and medium-sized mold with a hot forging material of 5CrNiMo and a height of 370 mm is used as an example, and the mold undergoes forging, annealing, quenching, tempering and laser cladding processes in sequence.

[0046] A method for improving the service life of a hot forging die, specifically comprising the following steps:

[0047] S1: Forging, the initial forging temperature is 1250°C, the final forging temperature is 830°C, and the air cooling is 40s.

[0048]S2: annealing, heating the mold to 810°C, holding for 4.5h, cooling to 320°C, out of the furnace, air-cooling to room temperature, sampling 4 points, and performing step S3 when the hardness is 185HB-210HB, otherwise, repeating step S2.

[0049] S3: Quenching, heating the mold, the heating process adopts the gradient heating method, the heating rate is 150°C / h, and when the temperature is 350°C, 540°C, and 720°C, the temperature is kept for 1-1.5h, heated to 860°C, and the temperat...

Embodiment 3

[0057] In this embodiment, a large mold with a hot forging material of 5CrNiMo and a height of 380 mm is used as an example, and the mold undergoes forging, annealing, quenching, tempering and laser cladding in sequence.

[0058] A method for improving the service life of a hot forging die, specifically comprising the following steps:

[0059] S1: Forging, the initial forging temperature is 1300°C, the final forging temperature is 850°C, and the air cooling is 60s.

[0060] S2: Annealing, heating the mold to 820°C, holding for 5h, cooling to 375°C, out of the furnace, air-cooling to room temperature, sampling 4 points, and performing step S3 when the hardness is 185HB-210HB, otherwise, repeating step S2.

[0061] S3: Quenching, heating the mold, the heating process adopts the gradient heating method, the heating rate is 170°C / h, and when the temperature is 350°C, 540°C, 720°C, the temperature is kept for 1.5h, then heated to 870°C, kept for 6 hours, and released from the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com