Semiconductor dehumidifier

A semiconductor and dehumidifier technology, applied in the direction of refrigerators, mechanical equipment, machine operation modes, etc., can solve the problems of refrigerant destroying the ozone layer, environmental pollution, waste of resources, etc., to achieve enhanced dehumidification effect, good heat transfer effect, reduce The effect of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

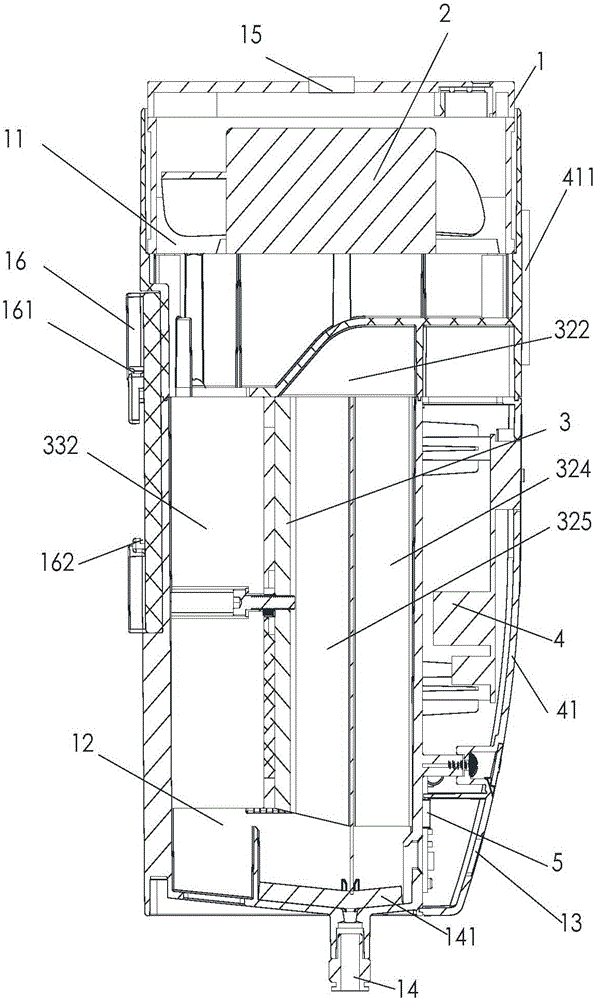

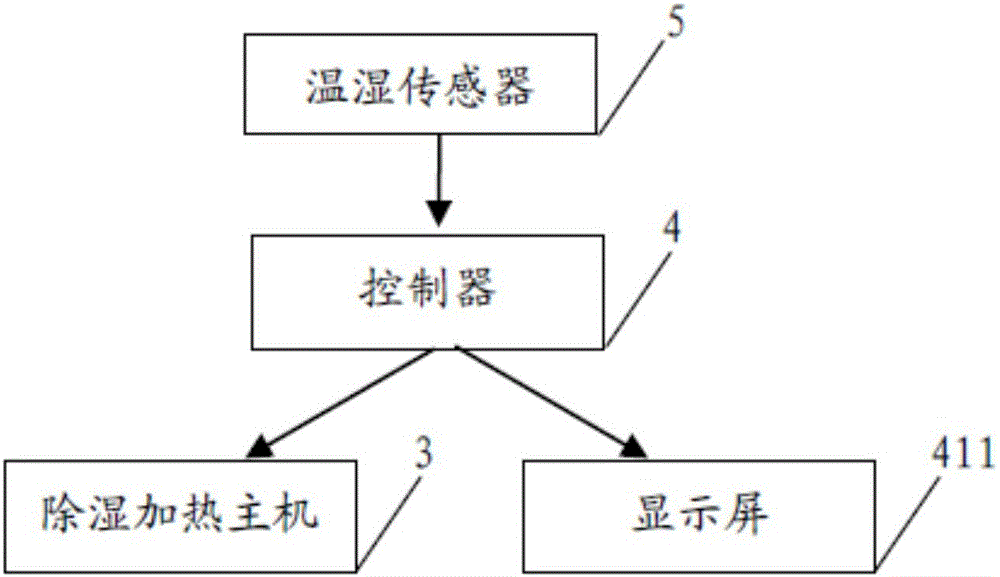

[0039] refer to figure 1 , a semiconductor dehumidifier, including a chassis 1, an exhaust fan 2, a dehumidification heating host 3, a controller 4 and a temperature and humidity sensor 5, the chassis 1 includes a first chamber 11, a second chamber 12, and a chassis air inlet 13 , the cabinet drain port 14 and the cabinet air exhaust port 15; the first chamber 11 is arranged above the second chamber 12; the exhaust fan 2 is installed in the first chamber 11; the dehumidification and heating host 3 is installed In the second chamber 12; the cabinet air inlet 13 is arranged at the lower end of the side wall of the cabinet 1 and communicates with the second chamber 12; the cabinet drain 14 is arranged at the bottom of the cabinet 1; the cabinet drains Water-absorbent cotton 141 is laid on the mouth 14; the cabinet air outlet 15 is installed on the upper end of the first chamber 11, and communicates with the first chamber 11; the controller 4 is installed on the side of the cabine...

Embodiment 2

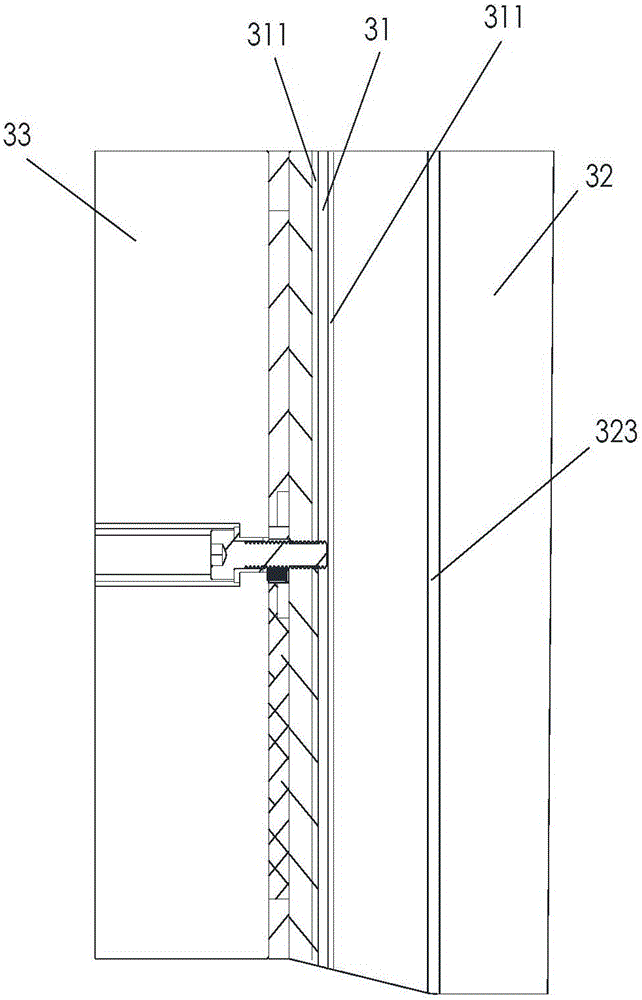

[0045] refer to Figure 4 and combine Figure 5 , the feature of this embodiment is that: the cold end radiator 32 also includes several first fins 326; the several first fins 326 are vertically installed on the surface of the first fixing plate 321; the several first fins 326 A fin 326 is arranged at intervals and extends along the wind direction in the cold end radiator 32; the hot end heater 33 includes a plurality of second fins 333; the plurality of second fins 333 are vertically installed on the second fixed plate 331; the plurality of second fins 333 are arranged at intervals and extend along the wind direction of the hot end heater 33.

[0046] All the other structures and parameters are the same as in Example 1.

[0047] Both the first fins 326 and the second fins 333 can increase the contact surface with the air, the heat transfer effect is better, the efficiency of dehumidification and heating is higher, and the electric power consumed by the semiconductor dehumid...

Embodiment 3

[0049] The feature of this embodiment is that: the first fin 326 is coated with a thermally conductive material layer; the thermally conductive material layer is silicon carbide; other structures and parameters are the same as those in Embodiment 2.

[0050] The heat-conducting material layer can improve the heat transfer effect of the first fins 326 and further enhance the cooling and dehumidification effect of the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com