Sectional type tunnel smoke exhaust system and method by water curtain separation

A smoke exhaust system and segmented technology, which is used in mining equipment, earth-moving drilling, dust prevention, etc., can solve the problems of low smoke exhaust efficiency and inability to effectively eliminate fire smoke from the exhaust port, and achieve optimized smoke exhaust. The effect of reducing the influence of flue gas and improving the efficiency of smoke extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

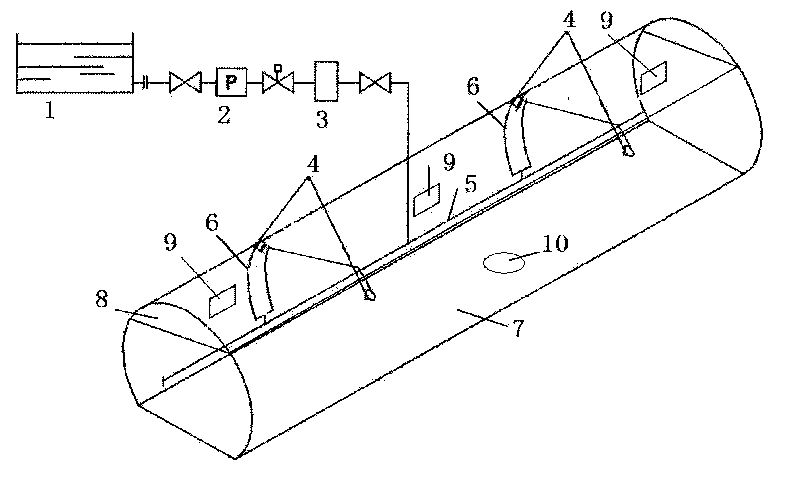

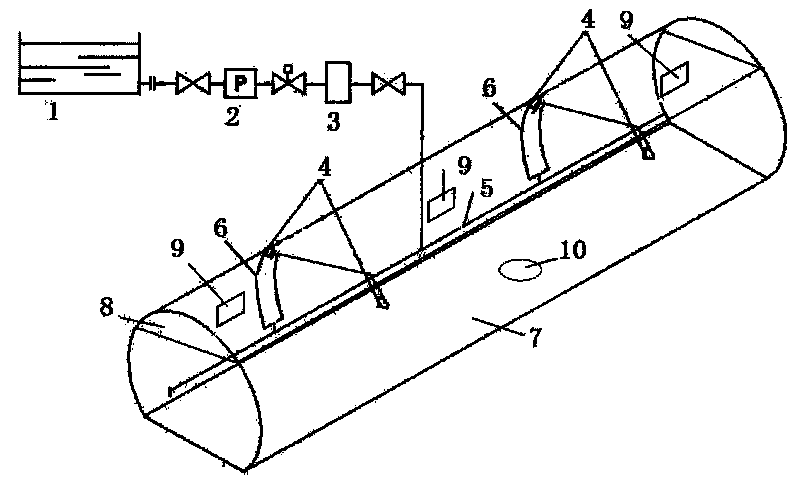

[0012] The features of the present invention and other related features will be described in further detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art:

[0013] As shown in the accompanying drawings, the numbers 1-10 represent respectively: fire pool 1, fire pump 2, mixer 3, water curtain nozzle 4, water curtain main pipe 5, water curtain branch pipe 6, tunnel 7, exhaust duct 8, exhaust Smoke mouth 9, fire source 10.

[0014] The parameters of the above devices are selected as follows: the volume of the fire pool is 50-100 cubic meters, the distance between the water curtains is 100-200 meters, the number of water curtain nozzles is not less than 2, and the cross-sectional area of the flue is 6 -12 square meters, the distance between the smoke outlets is 30-100 meters, and the size of the smoke outlets is 2-10 square meters. The specific selection value should be determined according to the traffic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com