Building public flue smoke discharging system and control method thereof

A technology of public flue and smoke exhaust system, which is applied in the field of public flue of buildings, can solve the problems that the negative pressure cannot be effectively transmitted, the system exhaust resistance increases, and the balance of fan dynamics is destroyed, so as to solve the problem of poor smoke exhaust, Improves pressure distribution and ensures safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

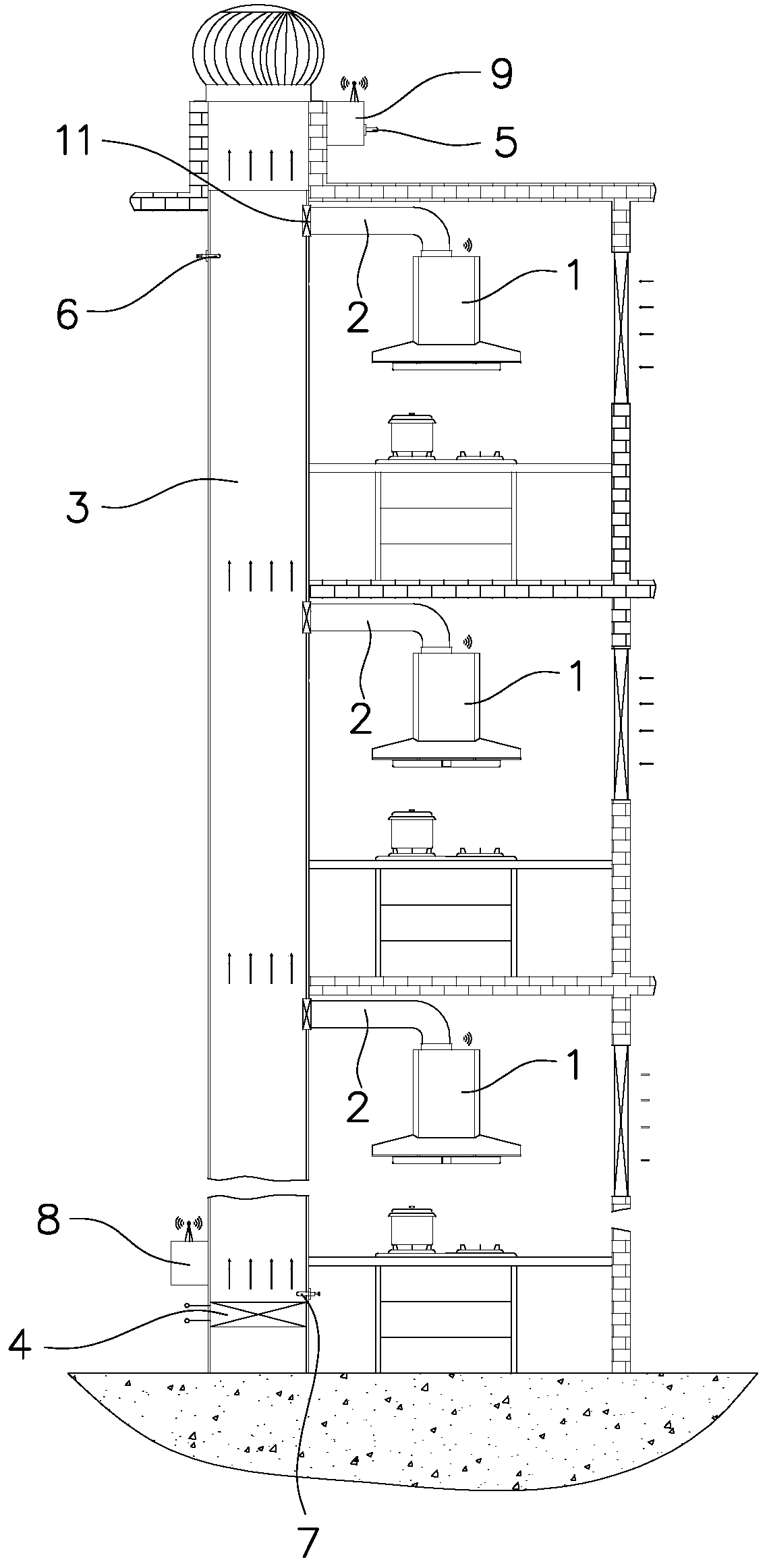

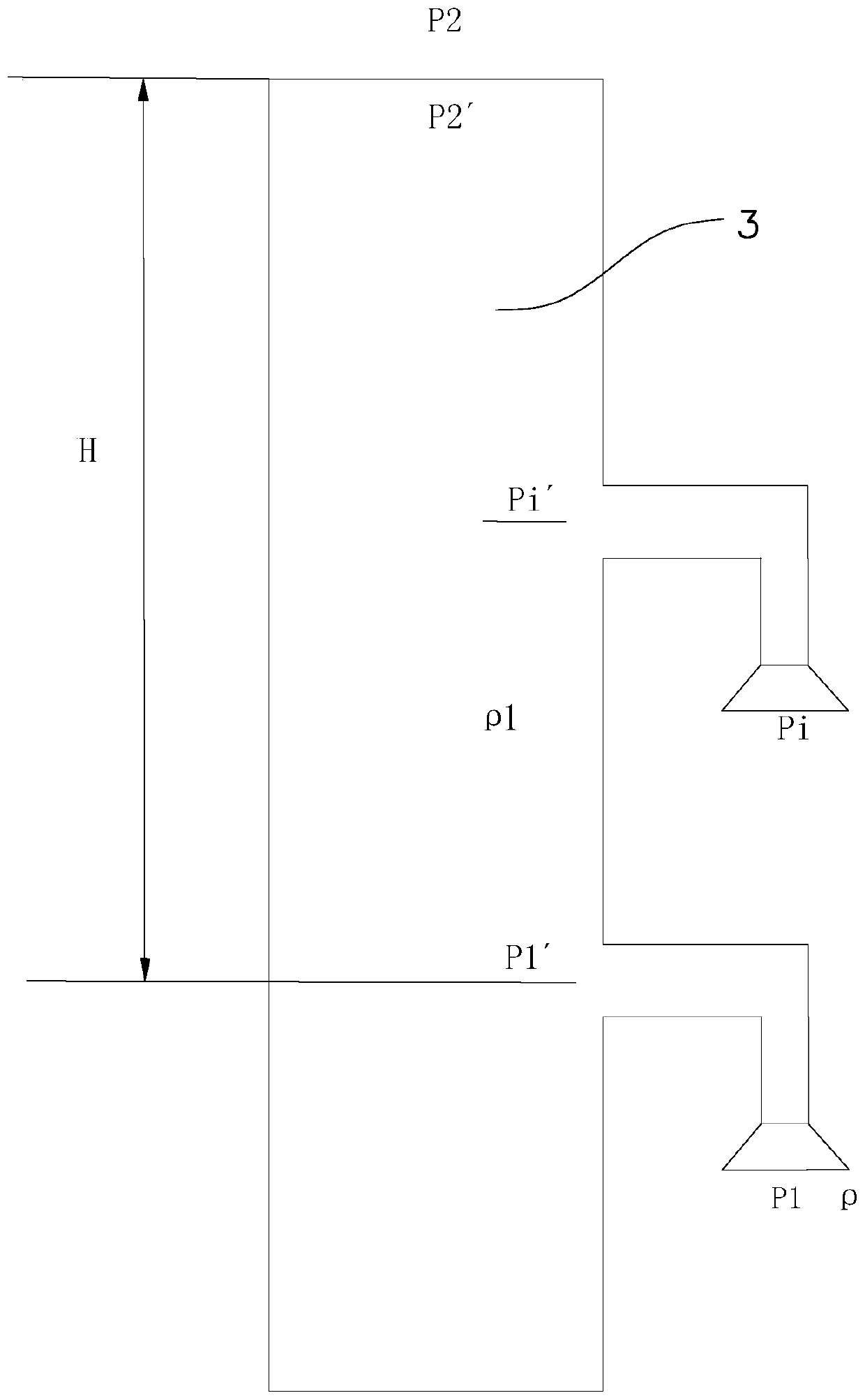

[0042] Such as figure 1 As shown, the smoke exhaust system for the public flue of the building in this embodiment includes range hoods 1 installed on different floors, and the air outlets of each range hood 1 are communicated with the public flue 3 through their respective smoke pipes 2. A fire damper 11 is installed at the outlet of the smoke pipe 2, which is prior art and will not be described in detail.

[0043] A heater 4 is installed at the bottom of the public flue 3 . The heater in this embodiment adopts electric heating, and the soot gas in the public flue 3 is heated by the heater 4 . A second temperature sensor 6 and a third temperature sensor 7 are installed in the public flue 3. The second temperature sensor 6 is installed near the oil fume outlet to detect the temperature of the oil fume gas at the outlet in the public flue. The third temperature sensor 7 is arranged above the heater 4 and close to the heater 4, and is used for detecting the temperature of the ga...

Embodiment 2

[0061] Such as Figure 5 and Figure 6 As shown, this embodiment adds an air inlet device 10 on the basis of Embodiment 1. The air inlet device 10 is installed at the bottom of the public flue 3 and is located below the heater 4, and the air inlet of the air inlet device 10 faces the public Inside the flue 3.

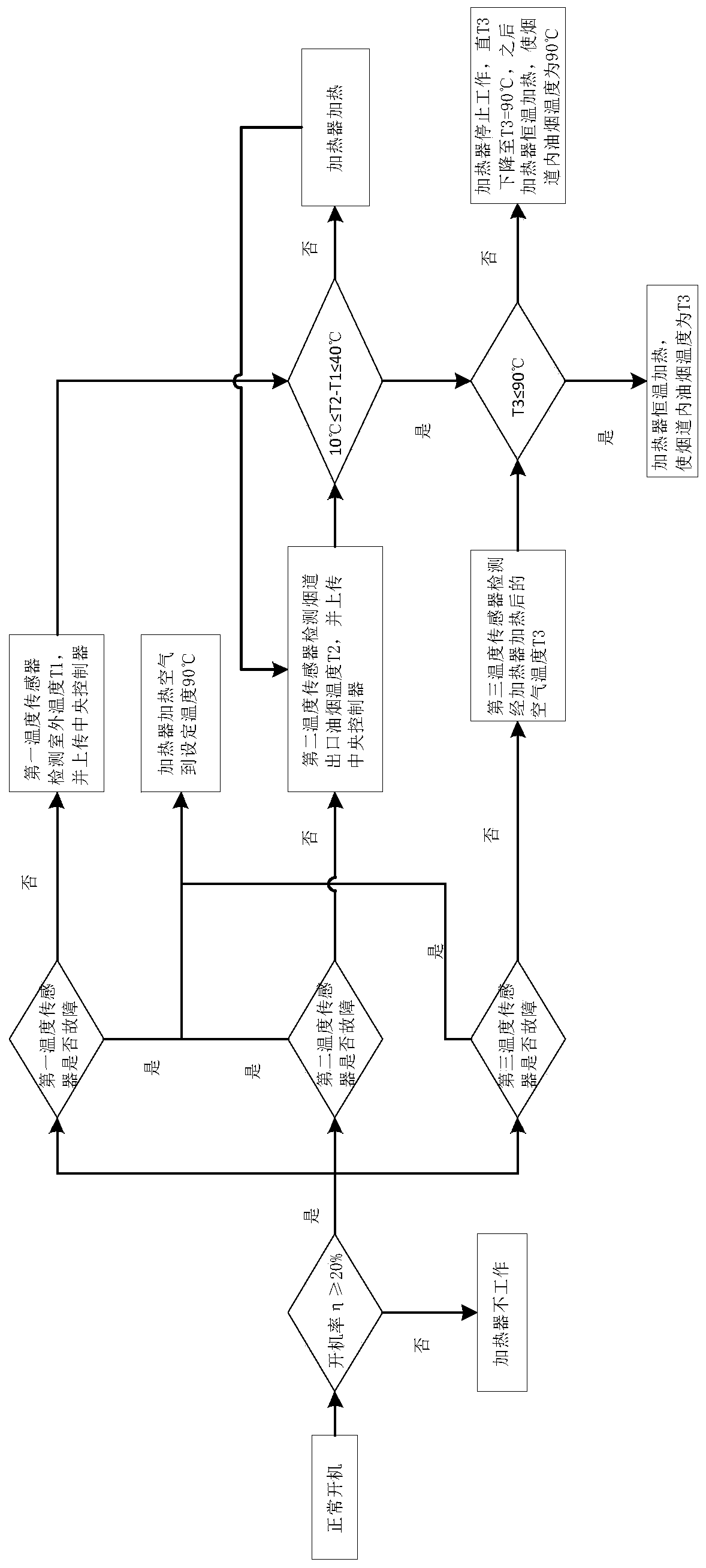

[0062] The control method of the building public flue smoke exhaust system in this embodiment includes the following steps:

[0063] ①. After installing the system, enter the total number of floors N;

[0064] ②, start the range hood, collect the start signal to count n, and calculate the start rate η=n / N;

[0065] ③. When the operating rate η<20%, the heater does not work;

[0066] ④. When the operating rate η>20%, the heater works;

[0067] ⑤. When 20%≤η<50%, the heater works and the air inlet device does not work;

[0068] ⑥. When η≥50%, the heater works and the air inlet device works synchronously;

[0069] ⑦. On the basis of the heater working, when the indo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com