High-hardness high-entropy alloy coating and preparation method and application thereof

A high-entropy alloy and high-hardness technology, which is applied in the field of high-entropy alloys, can solve problems such as low strength and hardness, great influence on wear performance, and poor wear resistance, and achieve good high-temperature wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

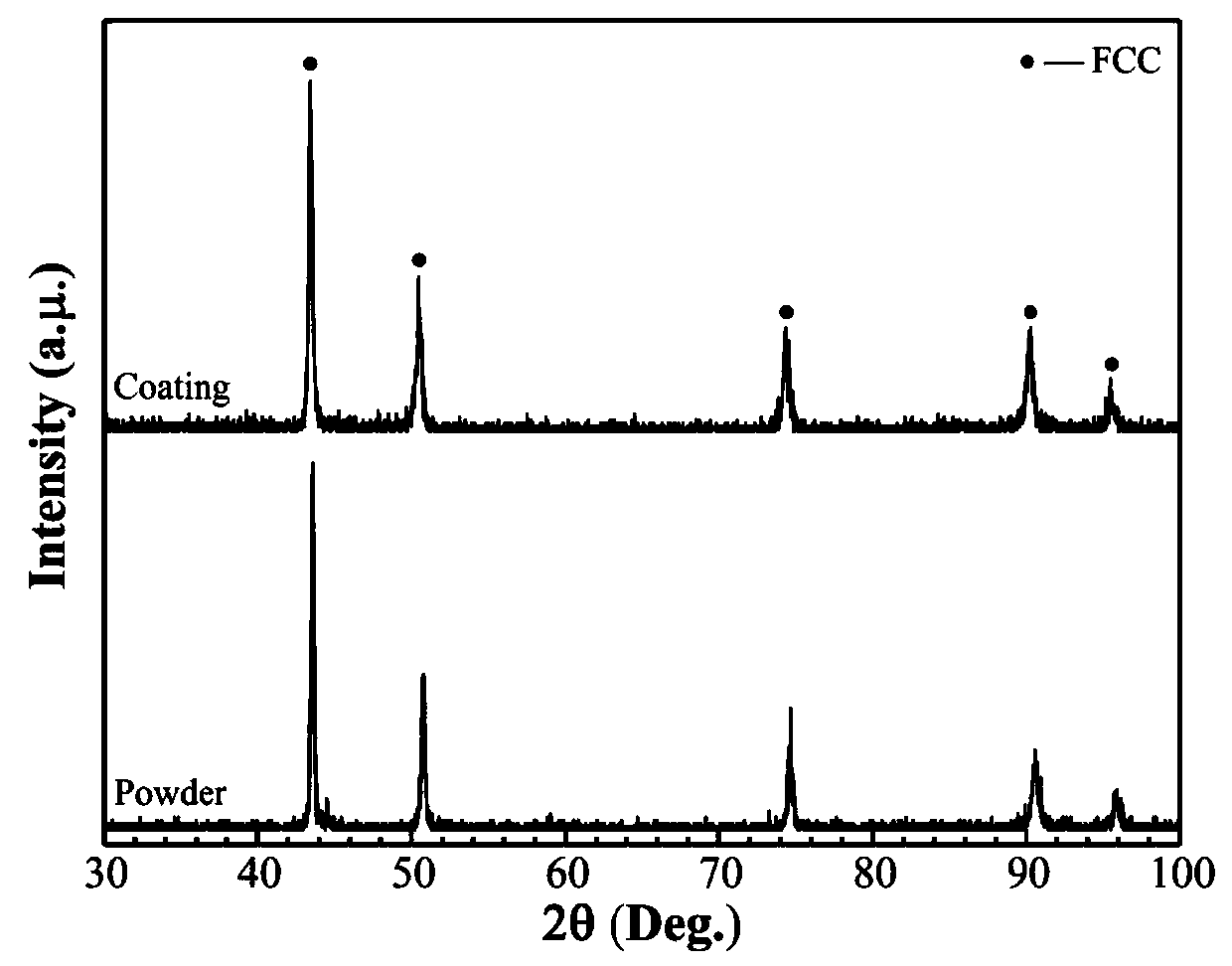

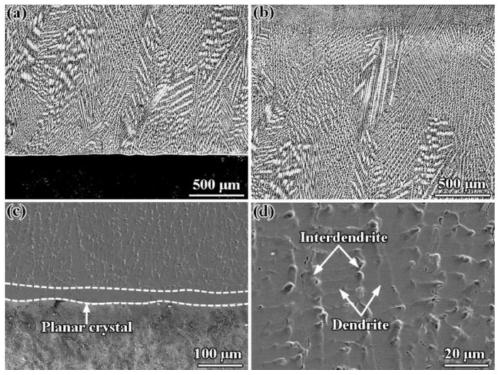

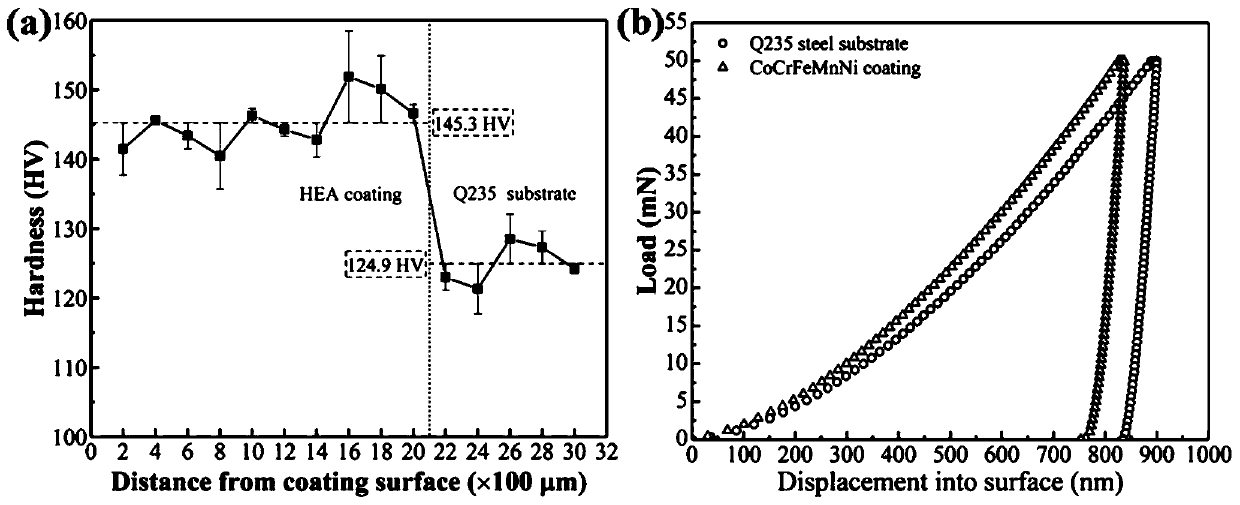

[0040] A high-hardness high-entropy alloy coating, the composition and atomic ratio are as follows: CoCrFeMnNiTi x V y , wherein x=0.3~1, y=0.1~1. Preferably, x:y=(0.5˜1):1. Further preferably, x:y=1:1. That is, the composition of the high-entropy alloy coating in this embodiment is: CoCrFeMnNiTiV.

[0041] The CoCrFeMnNi high-entropy alloy powder is spherical, the particle size of the spherical powder is 53-150 μm, and the purity is greater than 99.5wt.%; the Ti powder is spherical or elliptical, the particle size is 19-80 μm, and the purity is greater than 99.9wt.%. Irregular rhombus, the particle size is 5-30 μm, and the purity is greater than 99.9wt.%.

[0042] A method for preparing a high-hardness high-entropy alloy coating, comprising the following steps,

[0043] S01, powder mixing: put the prepared CoCrFeMnNiTiV alloy powder in a mixer for at least 4 hours, and the mixing frequency is 50-100 Hz;

[0044] S02, drying: place the mixed alloy powder in a drying oven...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is only:

[0073] A high-hardness high-entropy alloy coating, the composition and atomic ratio are as follows: CoCrFeMnNiTi 0.3 V 0.6 .

[0074] The parameters of the plasma cladding technology are: working current: 130A; working voltage: 25V; plasma arc forward speed: 75mm / min; plasma arc swing speed: 900mm / min; powder feeding rate: 5g / min; ion gas rate: 1.2L / min; powder feeding gas rate: 1.5L / min; protective gas rate: 6L / min; ion gas, powder feeding gas and protective gas are all argon.

Embodiment 3

[0076] The difference between this embodiment and embodiment 1 is only:

[0077] A high-hardness high-entropy alloy coating, the composition and atomic ratio are as follows: CoCrFeMnNiTi 0.6 V.

[0078] The parameters of the plasma cladding technology are: working current: 190A; working voltage: 40V; plasma arc forward speed: 130mm / min; plasma arc swing speed: 1500mm / min; powder feeding rate: 20g / min; ion gas rate: 3.5L / min; powder feeding gas rate: 4.2L / min; protective gas rate: 12L / min; ion gas, powder feeding gas and protective gas are all argon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com