Ce-Y-containing A1-Ti-N multicomponent composite coating and preparation thereof

A multi-component compounding and coating technology, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problem of reducing the performance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

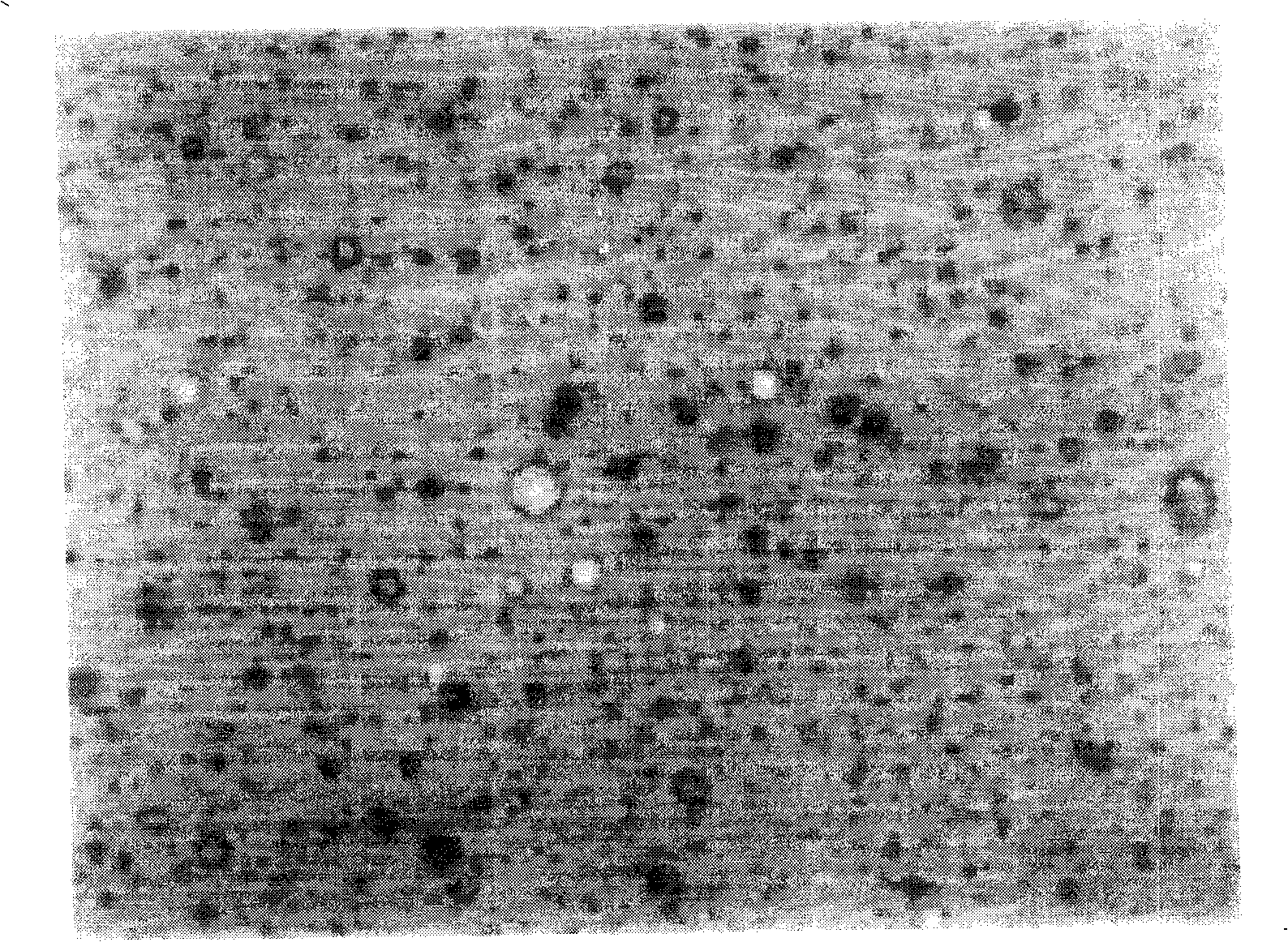

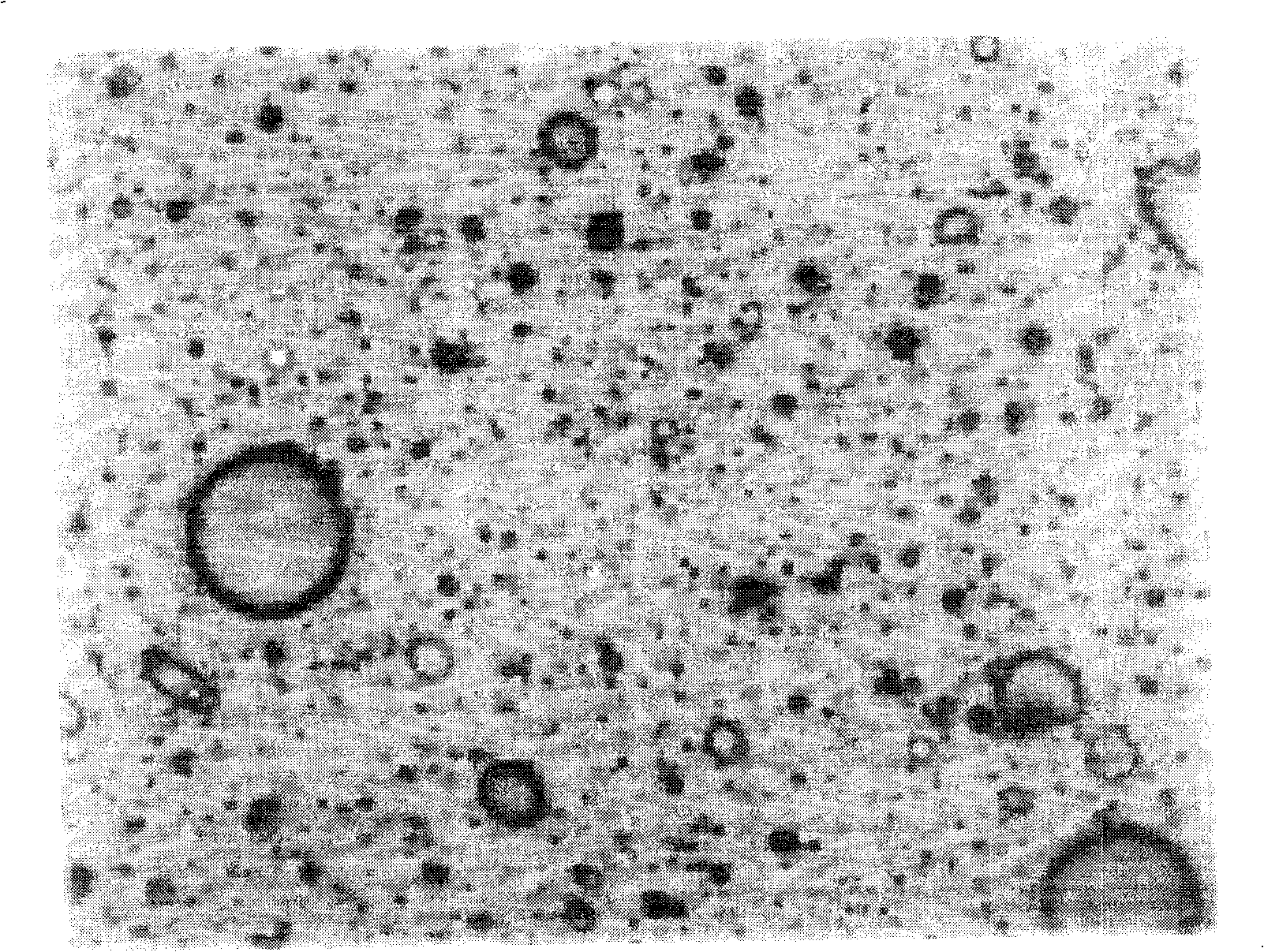

Image

Examples

Embodiment 1

[0032] A. Put the workpiece into an acetone solution with a concentration of 10% and ultrasonically clean it for 15 minutes, then dry it in an oven;

[0033] B. Put the above-mentioned processed workpiece on the turntable in the vacuum chamber, close the door of the vacuum chamber, turn on the switch of the main switch of the equipment and the switch of the rotating mechanism, so that the cooling system starts to work and the turntable rotates;

[0034] C. Turn on the vacuum system, vacuumize the vacuum chamber, and the pressure in the vacuum chamber reaches 6.0×10 -3 Pa;

[0035] D. Turn on the negative bias power supply, apply a negative bias voltage to -900V to the workpiece, open the solenoid valve on the gas pipeline leading to the vacuum chamber from the gas supply system, and deliver Ar gas to the vacuum chamber so that the pressure in the vacuum chamber is 1.0Pa. Ar ion cleaning for 10 minutes;

[0036] E. Turn on the negative bias power supply, apply a negative bias...

Embodiment 2

[0041] A. Put the workpiece into an ethanol solution with a concentration of 10% and ultrasonically clean it for 15 minutes, then dry it in an oven;

[0042] B. Put the workpiece after the above treatment on the turntable in the vacuum chamber, and close the vacuum chamber door. Turn on the main switch of the equipment and the switch of the rotating mechanism, so that the cooling system starts to work and the turntable rotates;

[0043] C. Turn on the vacuum system, vacuumize the vacuum chamber, and the pressure in the vacuum chamber reaches 6.0×10 -3 Pa;

[0044] D. Turn on the negative bias power supply, apply a negative bias voltage to -1000V to the workpiece, open the solenoid valve on the gas transmission line leading to the vacuum chamber from the gas supply system, and deliver Ar gas to the vacuum chamber so that the pressure in the vacuum chamber is 1.0Pa. Ar ion cleaning for 10 minutes;

[0045] E. Turn on the negative bias power supply, apply a negative bias volta...

Embodiment 3

[0050] A. Put the workpiece into an ethanol solution with a concentration of 10% and ultrasonically clean it for 15 minutes, then dry it in an oven;

[0051] B. Put the workpiece after the above treatment on the turntable in the vacuum chamber, and close the vacuum chamber door. Turn on the main switch of the equipment and the switch of the rotating mechanism, so that the cooling system starts to work and the turntable rotates;

[0052] C. Turn on the vacuum system, vacuumize the vacuum chamber, and the pressure in the vacuum chamber reaches 6.0×10 -3 Pa;

[0053] D. Turn on the negative bias power supply, apply a negative bias voltage to -1000V to the workpiece, open the solenoid valve on the gas transmission line leading to the vacuum chamber from the gas supply system, and deliver Ar gas to the vacuum chamber so that the pressure in the vacuum chamber is 1.0Pa. Ar ion cleaning for 10 minutes;

[0054] E. Turn on the negative bias power supply, apply a negative bias volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Binding force | aaaaa | aaaaa |

| Anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com