Energy-efficient ceramic kiln burner

A ceramic kiln, high-efficiency and energy-saving technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as insufficient mixing, heat loss, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

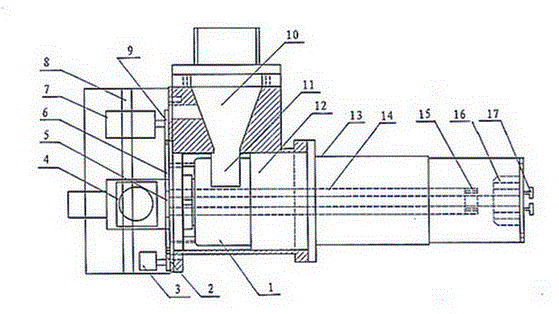

[0007] As shown in the attached figure, an air inlet chamber and an air outlet chamber form the base of the burner. There is a vent between the air inlet chamber and the air outlet chamber. The air supply pipe is connected to the air inlet chamber through the interface, and the air outlet chamber is cylindrical. The cylindrical shell is sealed with the flange of the air outlet chamber. The cylindrical shell forms the air supply pipe. The gas pipe is located in the cylindrical shell. The gas valve is connected to the rear end of the gas pipe. At the bottom of the combustion head, the front end of the gas nozzle is 20mm away from the bottom of the cup-shaped combustion head. An annular vent control baffle with a bottom plate is installed in the air outlet chamber. There is a bar-shaped air outlet on the baffle, and there is a rotating shaft in the middle of the bottom plate of the baffle. The rotating shaft passes through the wall of the air outlet chamber. A transmission gear is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com