Biodegradable micro-lubricating oil and preparation method thereof

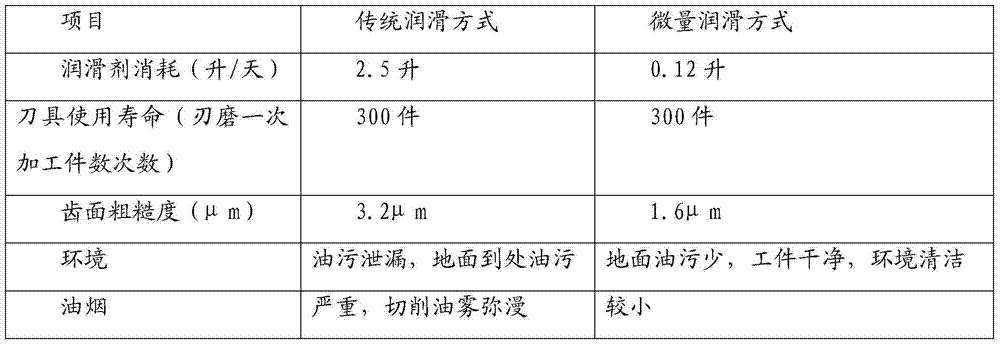

A lubricating oil and trace technology, applied in the field of lubrication, can solve the problems of large liquid usage, waste and leakage, not easy to degrade, etc., and achieve good biodegradability, excellent effect and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

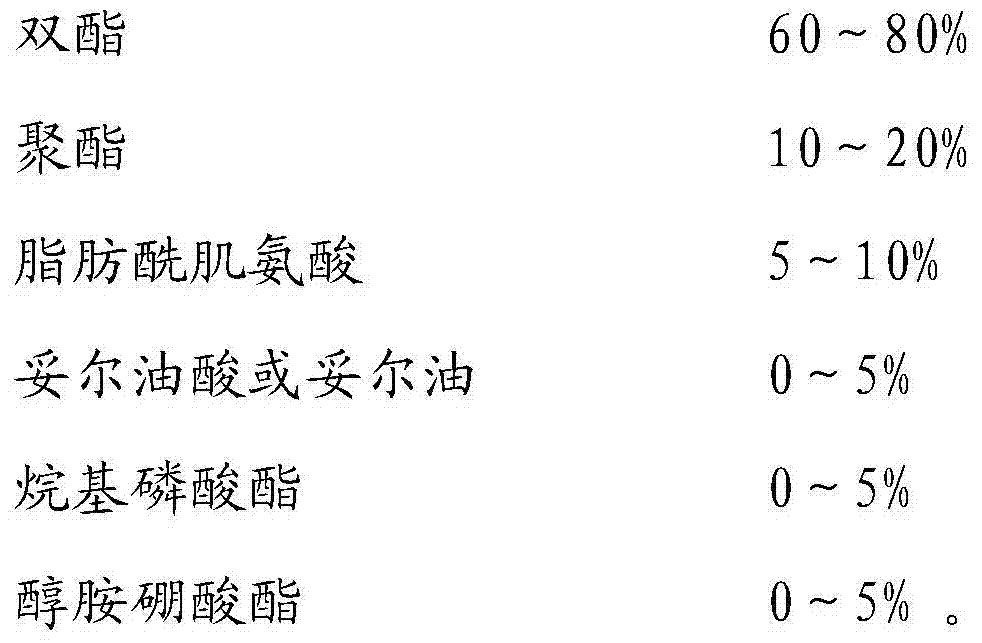

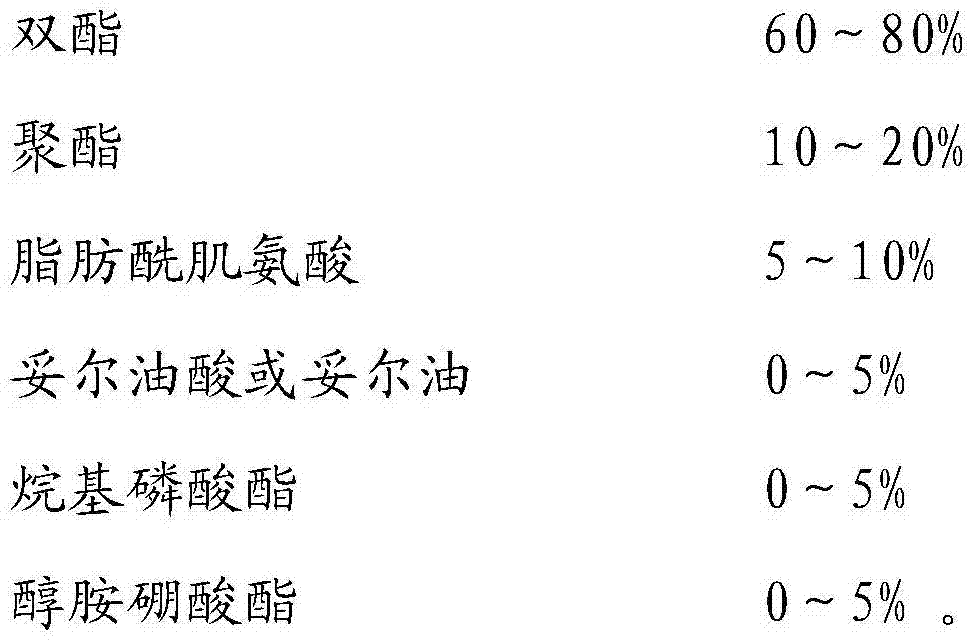

Method used

Image

Examples

Embodiment 1

[0035] Weigh 80kg of dioctyl adipate, 10kg of polyester 1#, 5kg of oleoyl sarcosine, 2kg of tall oleic acid, 2kg of oleyl alcohol phosphate, and 1kg of monoethanolamine borate and add them to the mixer at 40°C. Stir at high temperature for about 1 hour, and when the sample is completely transparent, it is biodegradable microlubricating oil.

[0036] The preparation method of above-mentioned polyester 1#: take 76.09kg (1000mol) of 1,3 propylene glycol and 202.25kg (1000mol) of sebacic acid and add in the polymerization kettle, add 2kg strongly acidic cation exchange resin and use nitrogen to replace the air in the kettle, The temperature is 220 DEG C, the reaction time is 8 hours, then a certain proportion of 5kg oleic acid is added for capping, the water is removed under reduced pressure, and the strongly acidic cation exchange resin is removed.

[0037] The biodegradable micro-lubricating oil prepared by the above method has the following physical and chemical indicators afte...

Embodiment 2

[0040] Weigh 60kg of dioctyl azelate, 20kg of polyester 2#, 10kg of lauroyl sarcosine, and 5kg of tall oil into a stirrer and stir for about 1 hour at a temperature of 60°C. When the sample is completely transparent, it is Biodegradable minimum quantity lubricant.

[0041] The preparation method of the above polyester 2#: Weigh 90.12kg (1000mol) of 1,4 butanediol and 174.19kg (1000mol) of sebacic acid into the polymerization kettle, add 1.6kg of strong acidic cation exchange resin and replace it with nitrogen gas air, at a temperature of 180° C. and a reaction time of 12 hours, then add a certain proportion of 4 kg of n-amyl alcohol for capping, remove water under reduced pressure, and remove the strongly acidic cation exchange resin.

Embodiment 3

[0043] Weigh 70kg of dioctyl sebacate, 15kg of polyester 2#, 8kg of oleoyl sarcosine, 5kg of lauryl phosphate, and 2kg of diethanolamine borate and add them to a stirrer and stir for about 1 hour at a temperature of 50°C , when the sampling observation is completely transparent, it is biodegradable microlubricating oil.

[0044] The biodegradable microlubricating oil prepared above is subjected to a biodegradable experiment:

[0045] 1. Experimental method: GB / T 21856-2008 Carbon dioxide generation test for rapid degradation of chemicals.

[0046] 2. Experimental materials:

[0047] 2.1 Oil: the biodegradable micro-lubricating oil prepared in Example 3 above.

[0048] 2.2 Inoculum: Take soil from 0-10cm above the ground in different places. After mixing and removing impurities, the soil samples are soaked and stirred in deionized water to get the supernatant.

[0049] 3. Experimental results:

[0050] Calculate the 28-day biodegradation rate: 88.32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com