Equipment and method for calcining alpha aluminum oxide by using aluminum oxide gaseous suspension calciner

A gaseous suspension, ɑ-alumina technology, applied in the preparation of alumina/hydroxide, etc., can solve problems such as single product, achieve the effect of improving utilization rate, improving market competitiveness and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

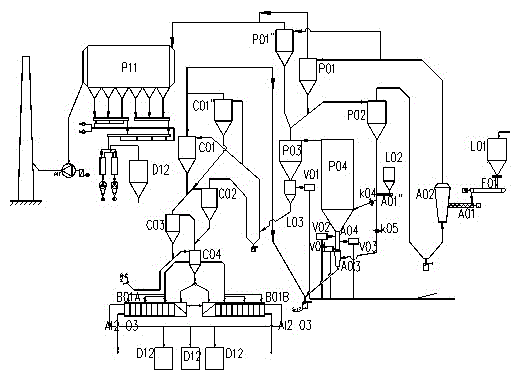

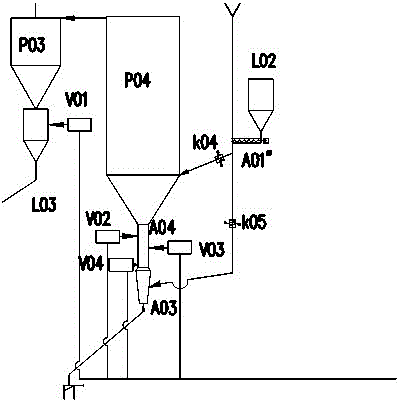

[0040] like figure 1 , 2 As shown, an alumina gaseous suspension roasting furnace is used for firing ɑ alumina, including: feeding system, alumina drying system, dust-containing waste gas filtration system, combined combustion station, roasting furnace P04, cyclone dust collector P03, Insulation retention tank L03, step-by-step cooler, the input end of the dust-containing exhaust gas filtration system is connected to the feeding system through the alumina drying system, and the output end of the dust-containing exhaust gas filtration system is connected to the end of the valve K04 and valve K05. The other end of the valve K04 is communicated with the roasting furnace P04; the other end of the valve K05 is communicated with the roasting furnace P04 through the combined combustion station; the roasting furnace P04 is communicated with the insulation retention tank L03 through the cyclone dust collector P03; The stage cooler and fluidized bed B01 are connected to the high tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com