Device for measuring pressure resistance of processed tomatoes

A technology for processing tomatoes and pressure resistance is applied in the field of devices for measuring and comparing the pressure resistance of processed tomatoes of different varieties, which can solve problems such as inconvenient observation, and achieve the effects of improving work efficiency, simple operation, and reducing labor intensity for testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

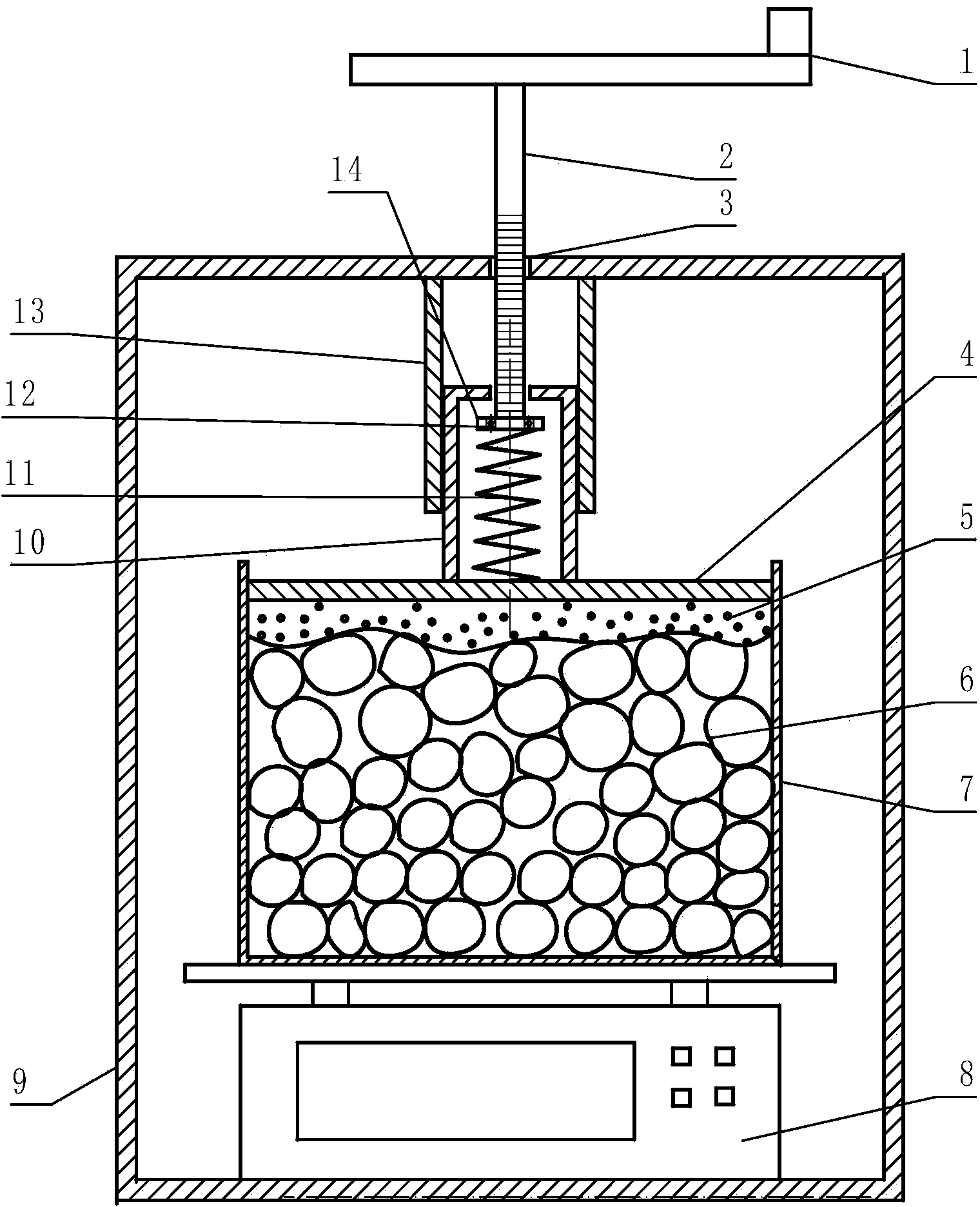

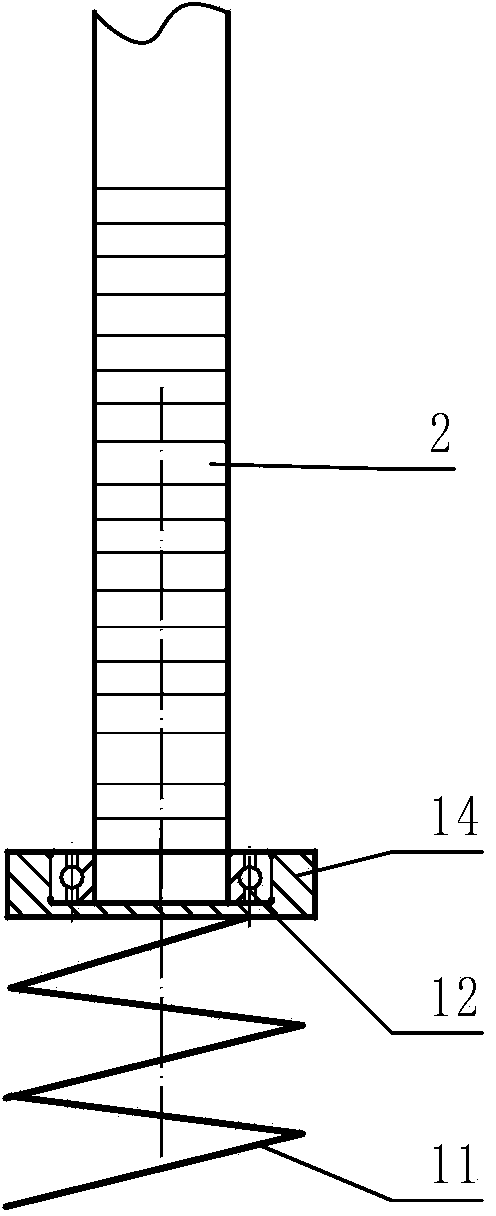

[0030] refer to figure 1 — Figure 4 , is a schematic structural diagram of Embodiment 1 of the present invention. A device for measuring the pressure resistance of processed tomato fruit, which is characterized in that it includes a hollow shell 9, a weighing platform 8 is arranged inside the hollow casing 9, and a fruit container 7 with an upper end opening is placed on the weighing platform 8 , the opening of the fruit container 7 is provided with a sliding platen 4 that can move up and down, the shape and size of the sliding platen 4 are compatible with the shape and size of the opening of the fruit container 7, and a sand cushion is provided below the sliding platen 4 Or a water cushion 5, a pressing device is arranged above the sliding pressing plate 4, and the pressing device acts on the sliding pressing plate 4 downwards, so that the sliding pressing plate 4 moves downward.

[0031] The structure of described pressing down device comprises rocking handle 1, screw rod...

Embodiment 2

[0038] Compared with Embodiment 1, the difference of this embodiment is that the lower end of the screw 2 is provided with a spherical shaft head 23, and the connecting block 14 is provided with a spherical groove 24, and the spherical shaft head 23 is embedded in the spherical groove It can be rotated within 24.

Embodiment 3

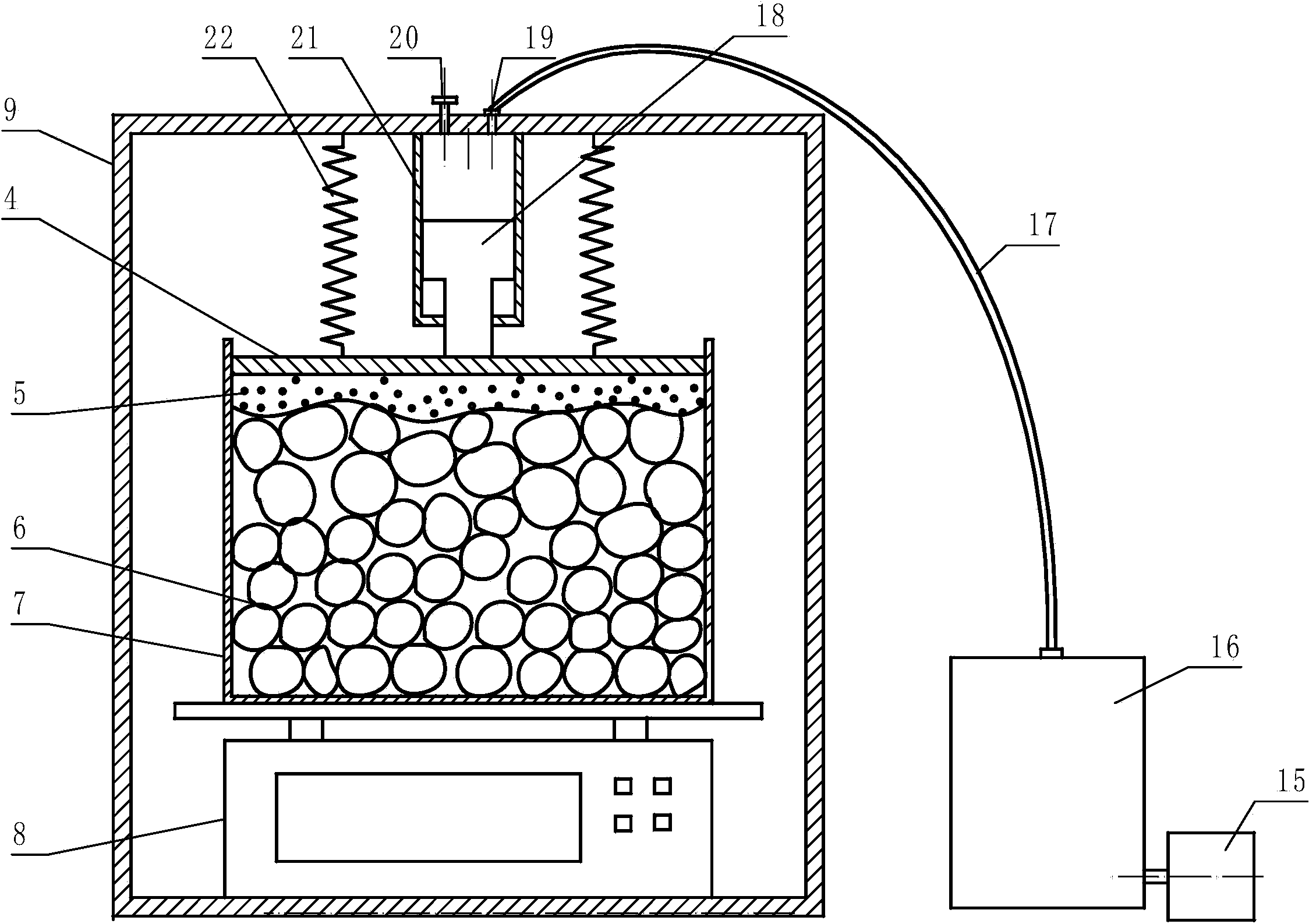

[0040] Compared with Embodiment 1, the difference of this embodiment is that the structure of the press-down device includes a tension spring 22, a cylinder 21, a piston 18, an intake pipe 17, a buffer tank 16, and a cylinder arranged on the sliding platen 4. 21 is fixedly connected with the inner top of the housing 9, the cylinder 21 is provided with a piston 18, the piston 18 is fixedly connected with the sliding platen 4 located below, and the cylinder 21 is provided with an air release valve 20 and an air inlet 19, and the air inlet 19 The buffer tank 16 is connected to the buffer tank 16 through the intake pipe 17, and the buffer tank 16 is connected to the inflation device 15; the tension spring 22 is arranged on the outside of the cylinder 21, one end is connected with the sliding pressure plate 4, and the other end is fixed on the inner top of the housing 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com