Method for continuous generation of SO3 gas

A gas, SO2 technology, applied in the field of sulfonation, can solve the problems of small investment and difficult to obtain sulfonation, and achieve the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

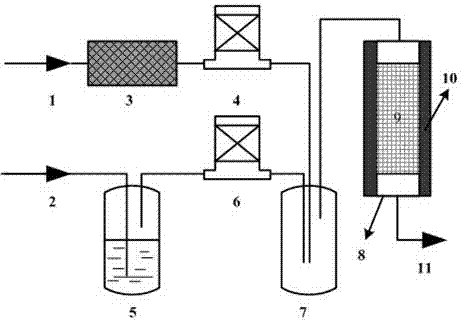

[0019] Such as Figure 1 As shown, control the needle regulating valve to make 0.1L / minSO 2 The gas is metered into the 2L buffer tank through the rotameter, and at the same time, the 1L / min air is controlled by the gas mass flow meter to enter the buffer tank, SO 2 The gas and air are mixed in the buffer tank, then washed in concentrated sulfuric acid, and then enter the reactor after passing through the stop valve and rotameter. The reactor is filled with vanadium pentoxide catalyst, the particle size is 5mm, and the filling volume is 0.3 L, both ends are fixed with stainless steel mesh, and the reaction temperature is controlled at 500 o C, obtained SO 3 The gas flow rate is 0.092L / min, and the concentration is 9.1%.

Embodiment 2

[0021] Such as Figure 1 As shown, control the needle regulating valve to make 0.8L / min SO 2 The gas is metered into the 9L buffer tank through the rotameter, and at the same time, the 6L / min air is controlled by the gas mass flow meter to enter the buffer tank, SO 2 After the gas and air are mixed in the buffer tank, they are washed in concentrated sulfuric acid, and then enter the reactor after passing through the stop valve and rotameter. The reactor is filled with vanadium pentoxide catalyst, the particle size is 7mm, and the filling volume is 1L , both ends are fixed with stainless steel mesh, and the reaction temperature is controlled at 520 o C, obtained SO 3 The gas flow rate is 0.63L / min, and the concentration is 10.2%.

Embodiment 3

[0023] Such as Figure 1 As shown, control the needle regulating valve to make 0.2L / min SO 2 The gas is metered into the 4L buffer tank through the rotameter, and at the same time the air is controlled to enter the buffer tank at 1L / min through the gas mass flow meter, SO 2 The gas and air are mixed in the buffer tank, then washed in concentrated sulfuric acid, and then enter the reactor after passing through the stop valve and rotameter. The reactor is filled with vanadium pentoxide catalyst, the particle size is 4mm, and the filling volume is 0.03 L, both ends are fixed with a stainless steel screen, and the reaction temperature is controlled at 550 o C, obtained SO 3 The gas flow rate is 0.18L / min, and the concentration is 17.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com