Micro-net dynamic membrane bioreactor for continuously updating dynamic membrane

A technology of bioreactor and dynamic membrane, which is applied in the direction of osmosis/dialysis water/sewage treatment, aerobic and anaerobic process treatment, etc. It can solve the problems of high idle rate of equipment, irregular fluctuation of effluent turbidity, difficulty in increasing effluent rate, etc. problems, to achieve the effect of increasing the membrane filtration area, good effluent quality, and reducing the volume of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

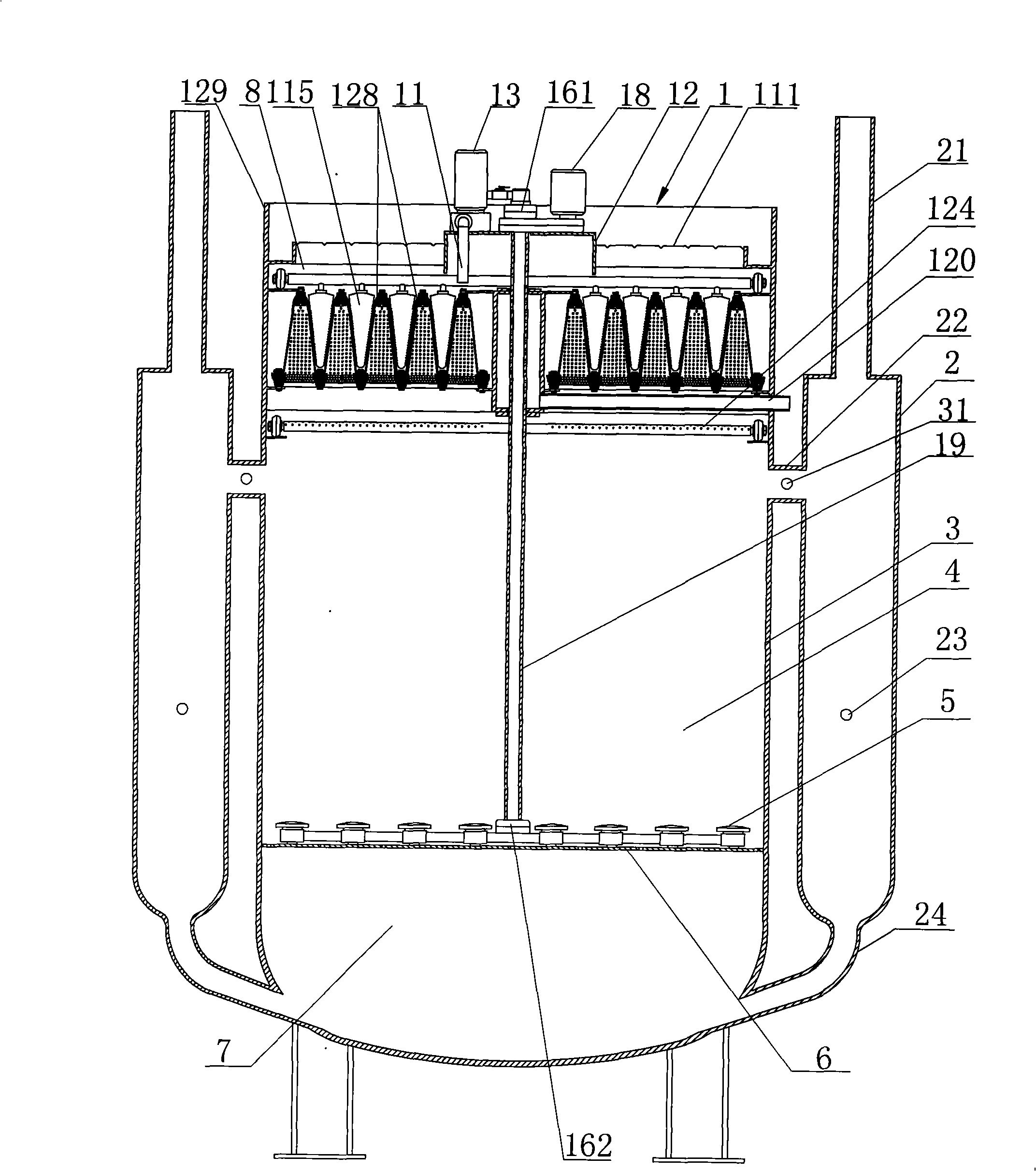

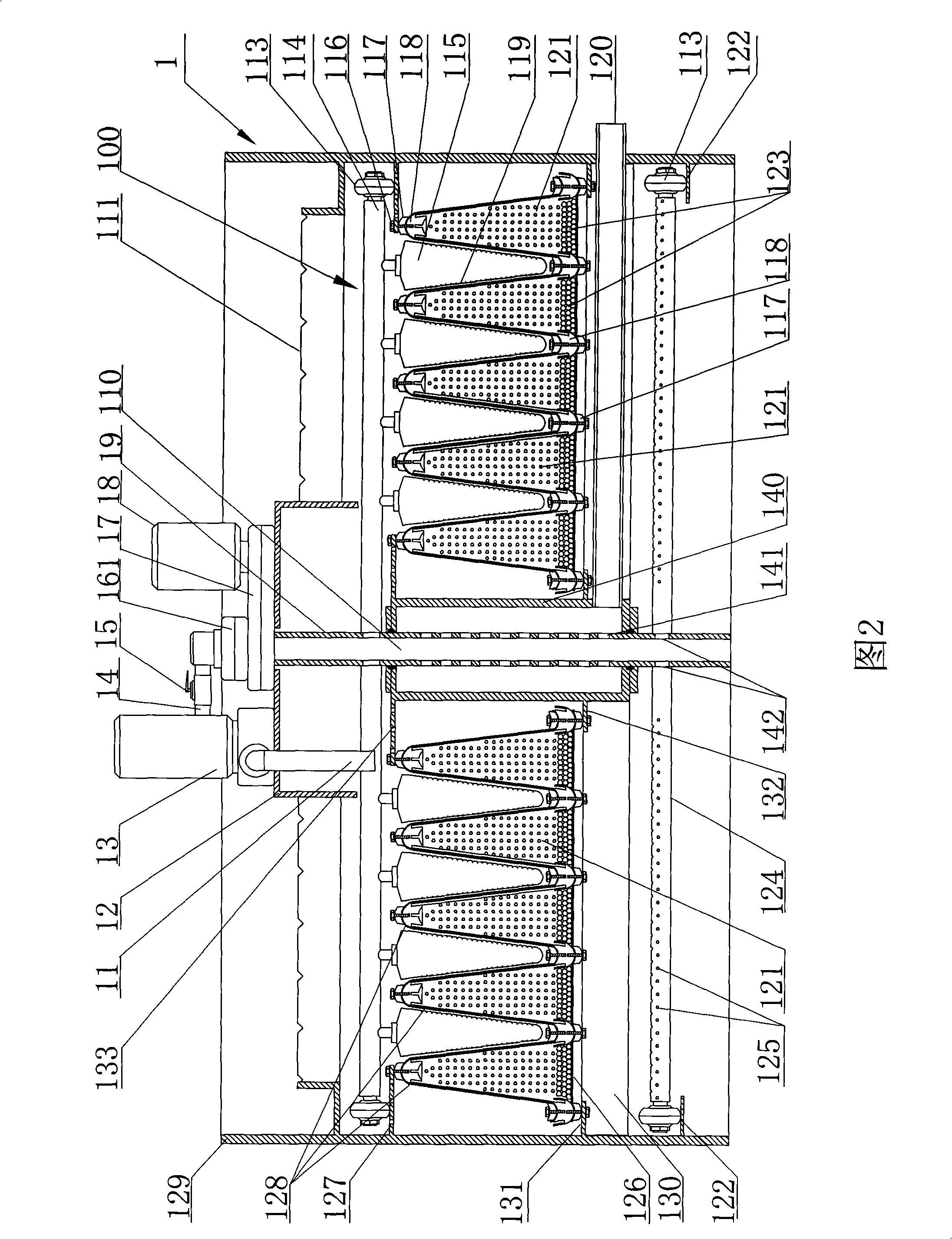

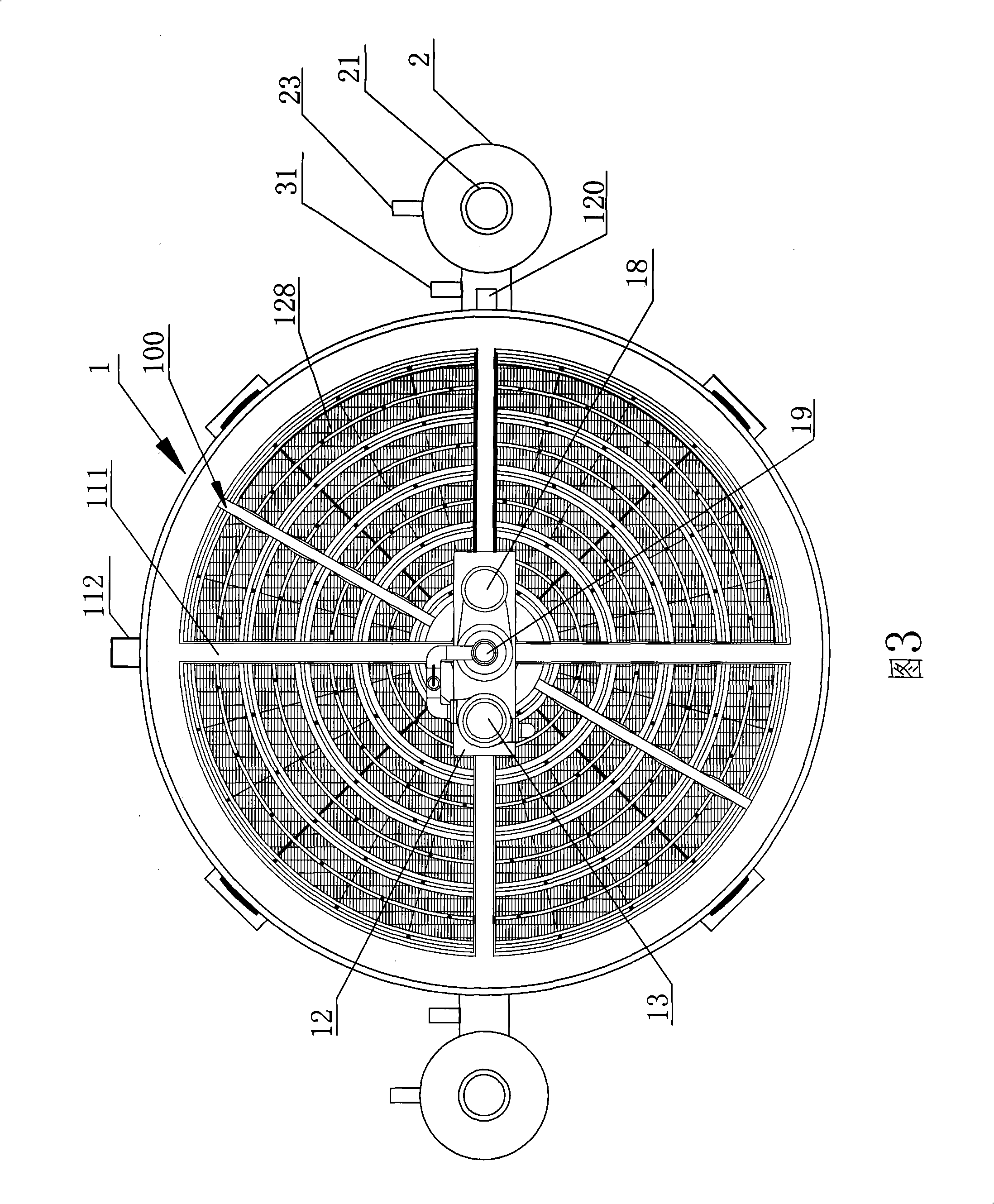

[0020] figure 1 ~Fig. 3 shows a kind of micro-grid dynamic membrane bioreactor which continuously updates the dynamic membrane. The aerobic zone 4, the clean water zone 8 collected by the water collection weir 111, the micro-grid assembly 1 carrying the dynamic membrane in the aerobic zone, the raw water inlet pipe 23, and the clean water outlet pipe 112 are characterized in that the above-mentioned container 3 is Cylindrical tank, the inside of the tank is divided into upper and lower layers by a tank body partition orifice 6 with several through holes, the upper layer is the aerobic zone 4, in which pollutants are aerobically biochemically digested; the lower layer is equipped with It is the anoxic zone 7, in which the anaerobic biochemical digestion of pollutants is mainly carried out while the biochemical denitrification process is carried out to further digest nitrogen and phosphorus substances; It is placed on the upper surface of the orifice plate 6 of the tank body, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com