Concrete slump testing device

A test device and slump technology, which is applied in the field of concrete slump test devices, can solve problems such as error-prone and cumbersome slump tests, and achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

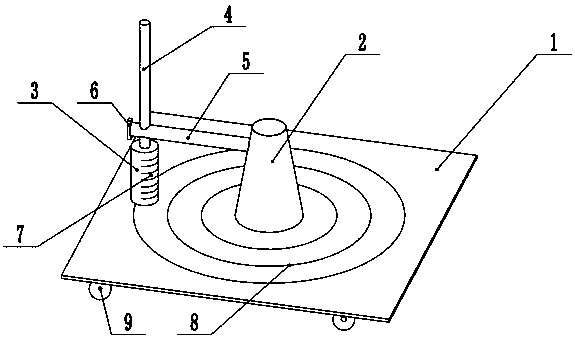

[0013] A concrete slump test device, such as figure 1 As shown, it includes a slump cylinder 2, the slump cylinder 2 is located above the test bench 1, a hydraulic cylinder 3 is provided on one side of the test bench 1, and a column 4 is provided on the hydraulic cylinder 3 , the column 4 is provided with a beam 5, one end of the beam 5 is fixed on the slump cylinder 2, and the other end is connected to the column 4 through a sleeve, and the end of the beam 5 is provided with a regulator 6. The height of the hydraulic cylinder 3 is 200mm, and a scale sticker 7 is provided on the outside. The test bench 1 is provided with a circular scale mark 8 that radially expands outward with the center point as the origin. Several universal wheels 8 are arranged below the described test bench 1 .

[0014] When using, lower the hydraulic cylinder 3 firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com