Sterile filling infusion system with automatic liquid feeding control

An aseptic filling and filling technology, which is applied in liquid bottling, packaging, liquid materials, etc., can solve the problems of multiple interfaces and dead ends of the dispenser, and achieve the effect of saving personnel operation, reducing pollution and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

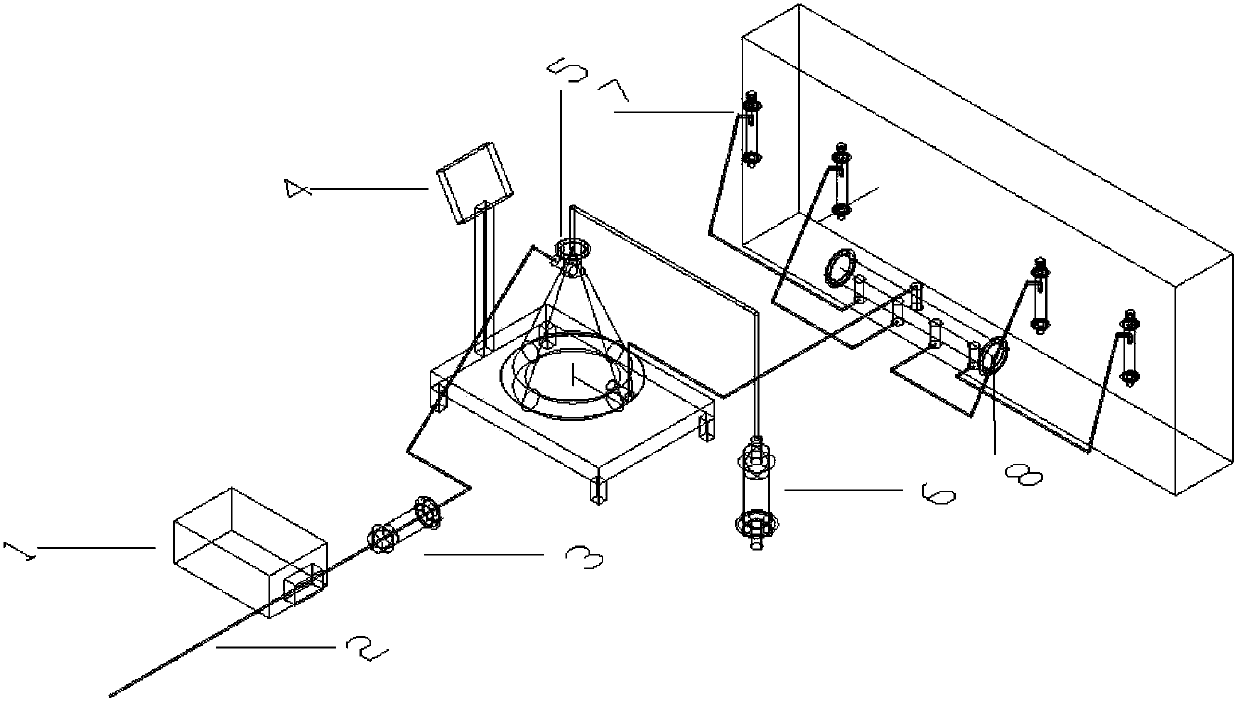

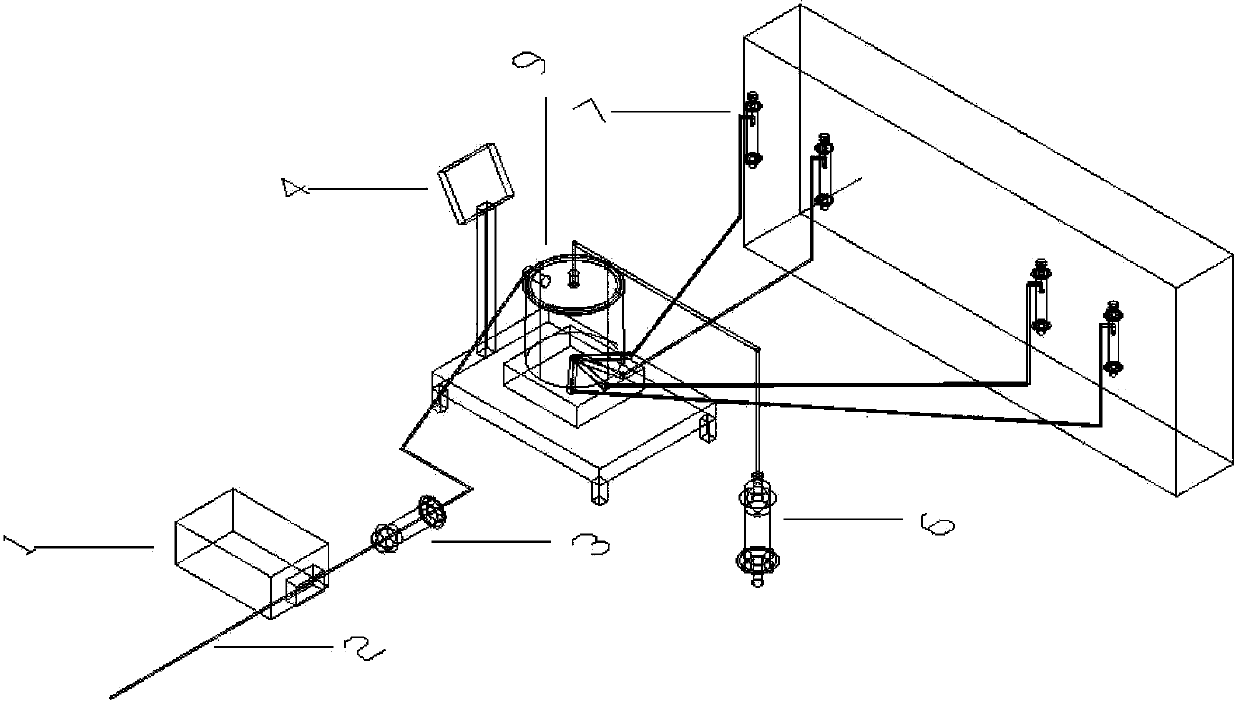

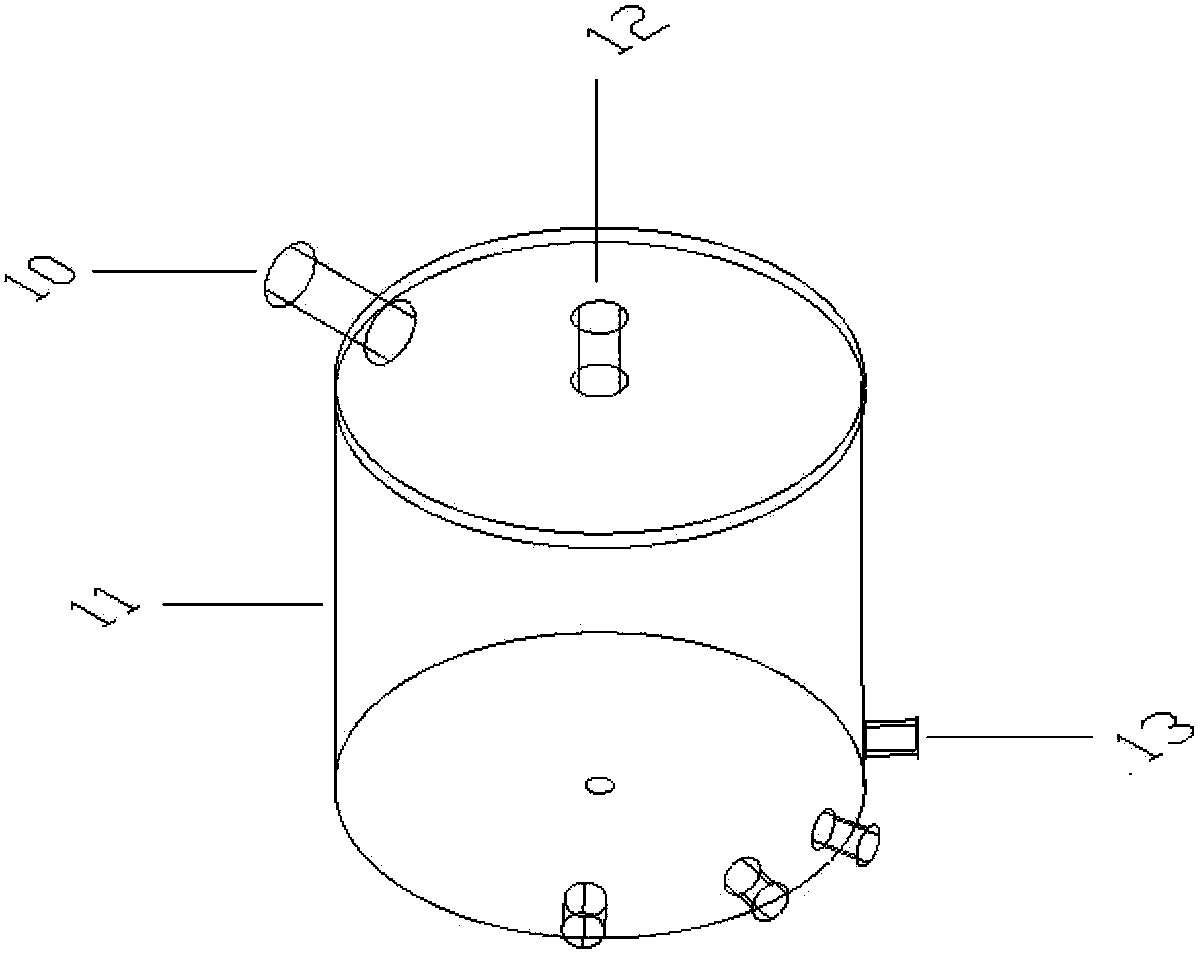

[0018] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0019] An aseptic filling and transfusion system for automatically controlling liquid intake, comprising a peristaltic pump, a terminal filter, an air filter, a liquid storage tank for an infusion tube, a platform scale and a filling pump, and the liquid storage tank is placed on the platform scale. After the peristaltic pump is started, the liquid medicine pumped out enters the liquid storage tank from the liquid inlet at the upper end of the liquid storage tank body through the terminal filter. When the liquid medicine in the liquid storage tank is weighed below the minimum value by the platform scale, the platform scale will send a signal to automatically start the peristaltic pump to inject the liquid medicine into the liquid storage tank; when the liquid medicine in the liquid storage tank is weighed by the platform scale, it reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com