Electrically enhanced internal anaerobic zero-valent iron reactor

An anaerobic reactor and zero-valent iron technology, applied in the field of water treatment, can solve the problems of long start-up period of anaerobic reactor, poor treatment performance, and easy to be interfered by other environmental factors, so as to overcome the deactivation of zero-valent iron phenomenon, promotion of redox process, acceleration of aggregation and metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

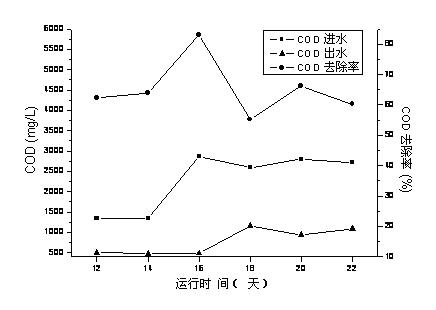

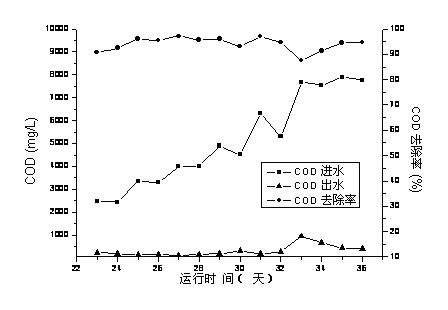

[0024] The above reactor was started and acclimatized with synthetic glucose wastewater see image 3 and Figure 4. It can be seen that under the condition of no voltage, the first 23 days of the reactor start-up, when the influent COD concentration is 1500 to 2500mg / L, the COD removal rate is basically lower than 60%. On the 24th day, the applied voltage of 1.4V was applied to the reactor, and the sewage treatment efficiency was rapidly increased to more than 90%. After running for 36 days, the influent COD is 7500mg / L, and the COD removal rate reaches over 95%, which realizes the rapid start-up of the reactor.

Embodiment 2

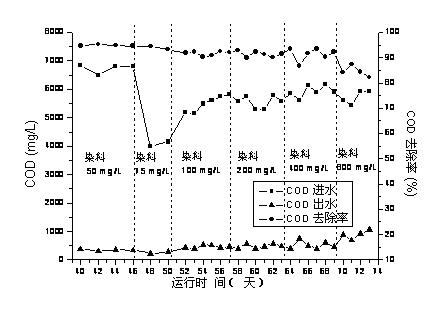

[0026] The situation of this reactor treating synthetic printing and dyeing wastewater under the condition of applied voltage is shown in Figure 5 During the period, it maintained stable operation. When the COD concentration in the influent water was around 5500mg / L, and when the dye concentration reached 800mg / L, the COD removal rate remained above 85%. Figure 6 It was shown that the average color removal rate remained above 80%.

Embodiment 3

[0028] From Figure 7 It can be seen that with the operation of the reactor, the particle size of the sludge in the reactor increases significantly, from the initial particle size of 152 microns to 381 microns on the 41d, indicating that the electro-enhanced anaerobic reactor can granulate the sludge The effect is obvious. At this time, the sedimentation rate of the sludge reaches 60m / h, and the iron content is about 3.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com