Simple fiberboard bending tester and testing method

A fiberboard, simple technology, applied in the simple fiberboard bending tester and testing field, can solve the problems of difference in results, standardization of difficult structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

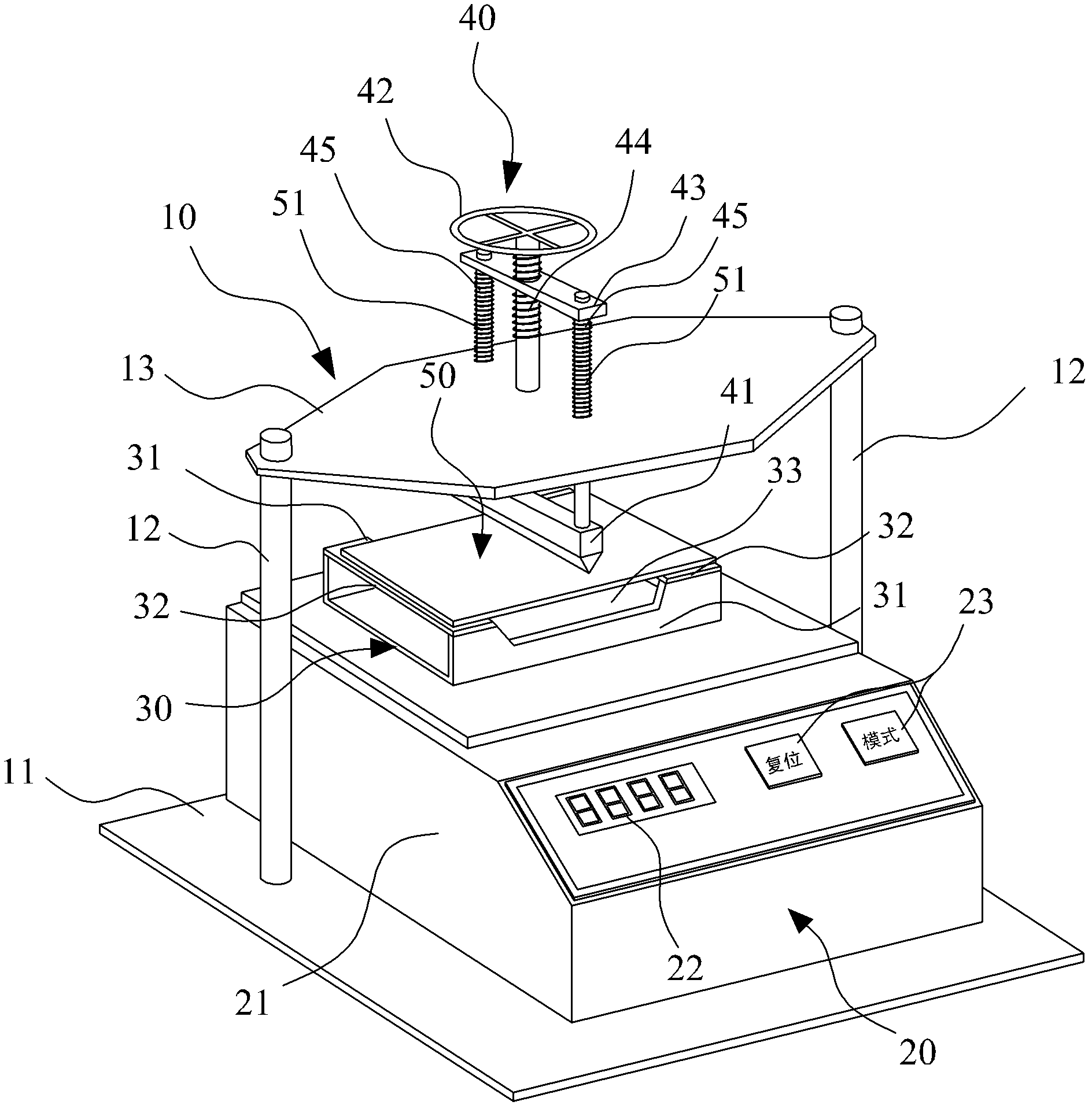

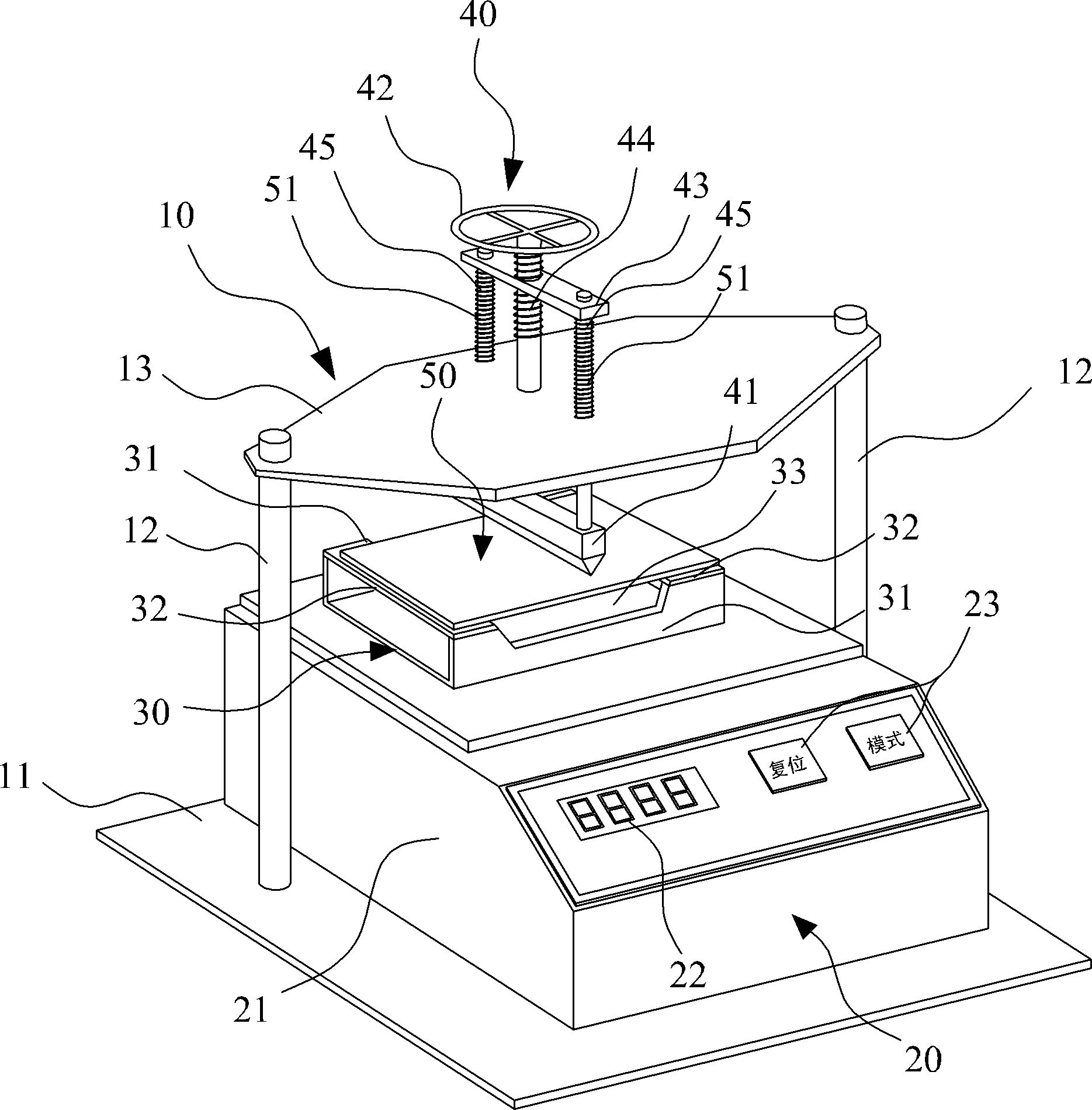

[0033] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a bracket 10 , a scale 20 , a pressure mechanism 40 , and a sample rack 30 .

[0034] Wherein, the support 10 includes a base plate 11, two pillars 12 longitudinally fixed on the base plate 11 and two support platforms 13 supported by the pillars 12. The two longitudinal pillars 12 and the support platform 13 form a space for placing the scale 20 . Wherein the bottom plate 11, the pillar 12 and the support platform 13 can be made of plastic material, wood or steel, which should meet the requirements of hard quality and not easily deformed. The bottom plate 11 in this embodiment is approximately square, the bracket 10 is cylindrical, and the bracket platform 13 is hexagonal. The connection method between the pillar 12 and the support platform 13 and the bottom plate 11 may be welding, screw fixing or adhesive connection.

[0035] The platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com