Mounting-free electric hoist energy efficiency test bench

An electric hoist and test bench technology, which is used in measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of high test time cost, inconvenient installation, low test efficiency, etc., and save test preparation time, installation and efficiency. The effect of easy disassembly and improved work reliability

Pending Publication Date: 2018-10-19

SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] (2) Pit and pre-buried are required

[0009] (3) The electric hoist is inconvenient to install

It requires the cooperation of multiple people, involves binding, lifting, installation, commissioning and other processes, and works at heights, making installation extremely inconvenient

[0011] (4) A qualified installation team is required, and testers cannot install by themselves

[0013] Sometimes the installation needs to be outsourced to a professional installation company, so the installation time needs to be coordinated with the installation company, and the installation efficiency is greatly reduced

[0014] (5) Low test efficiency

[0015] It takes a lon

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

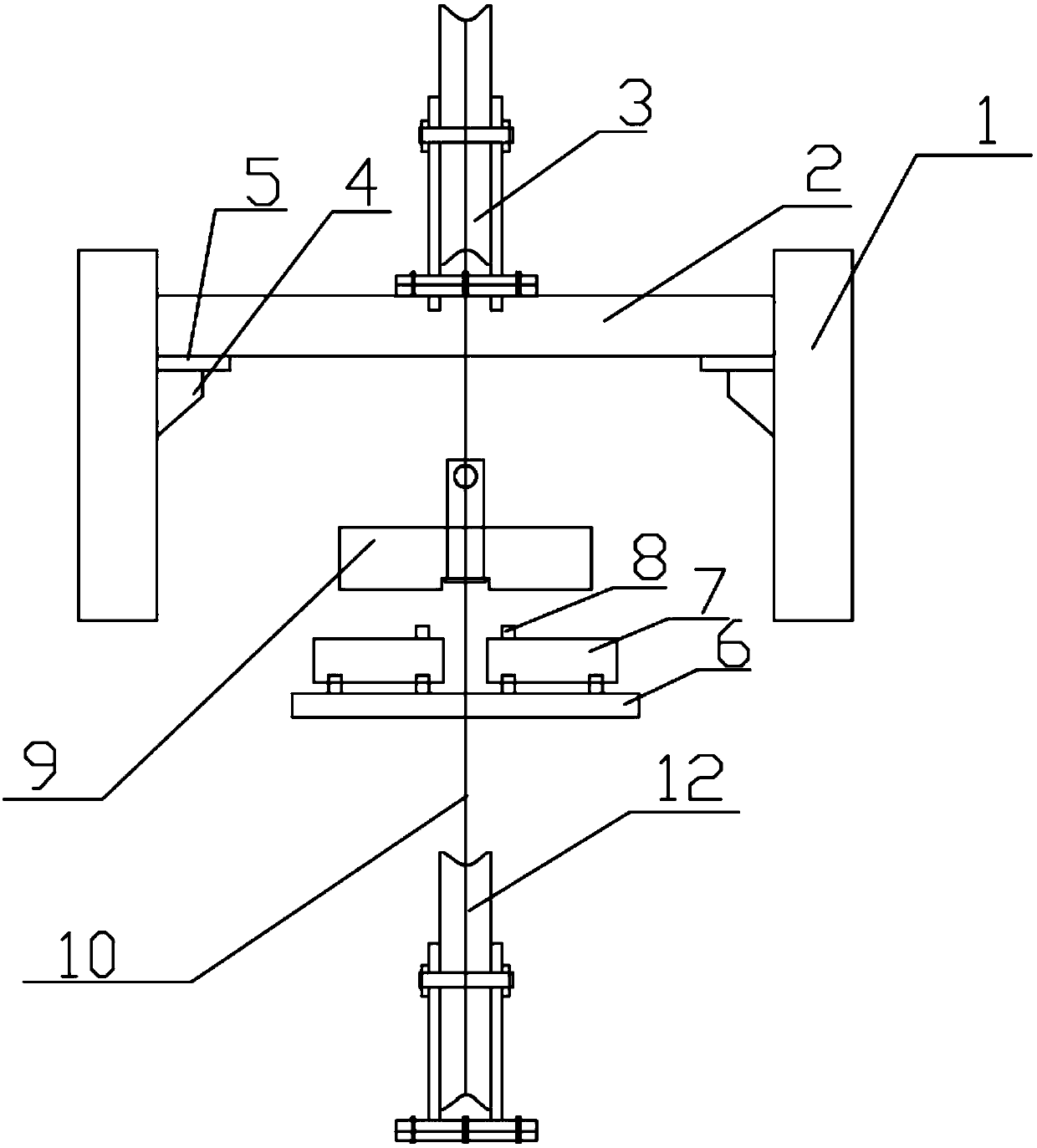

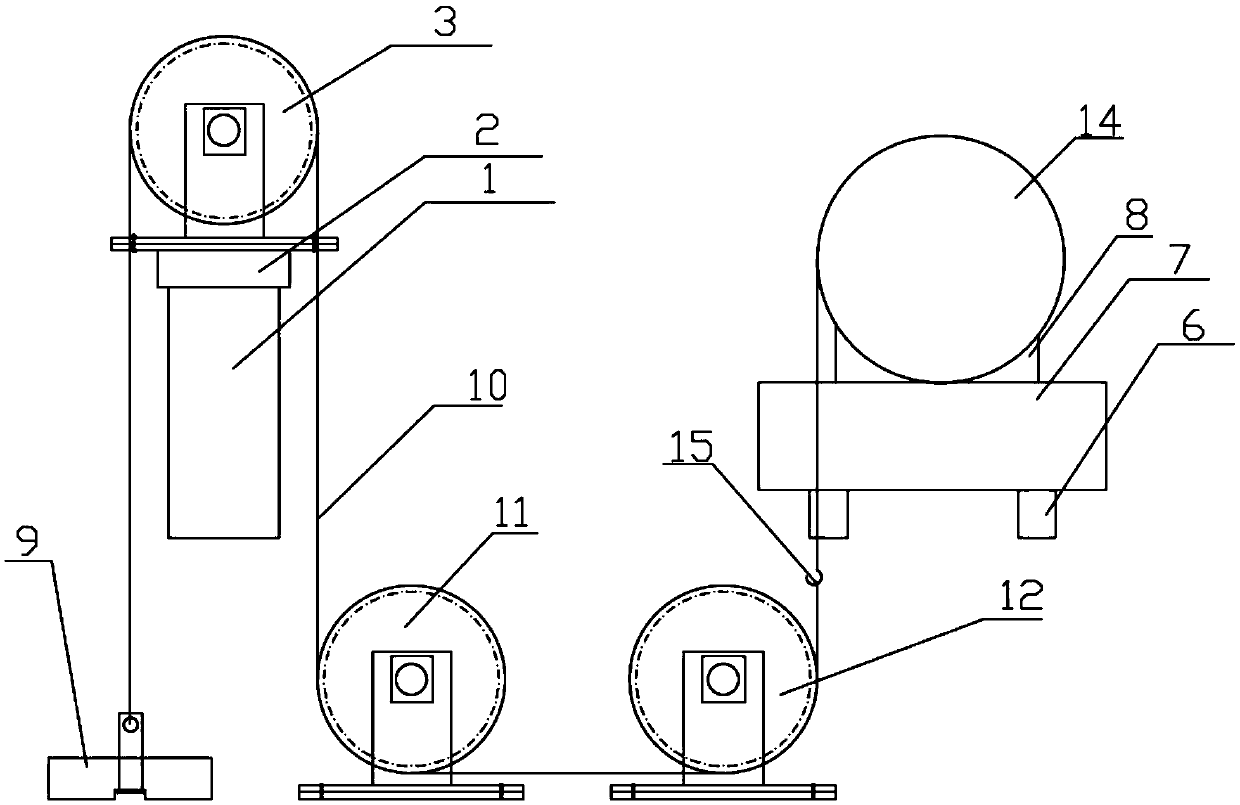

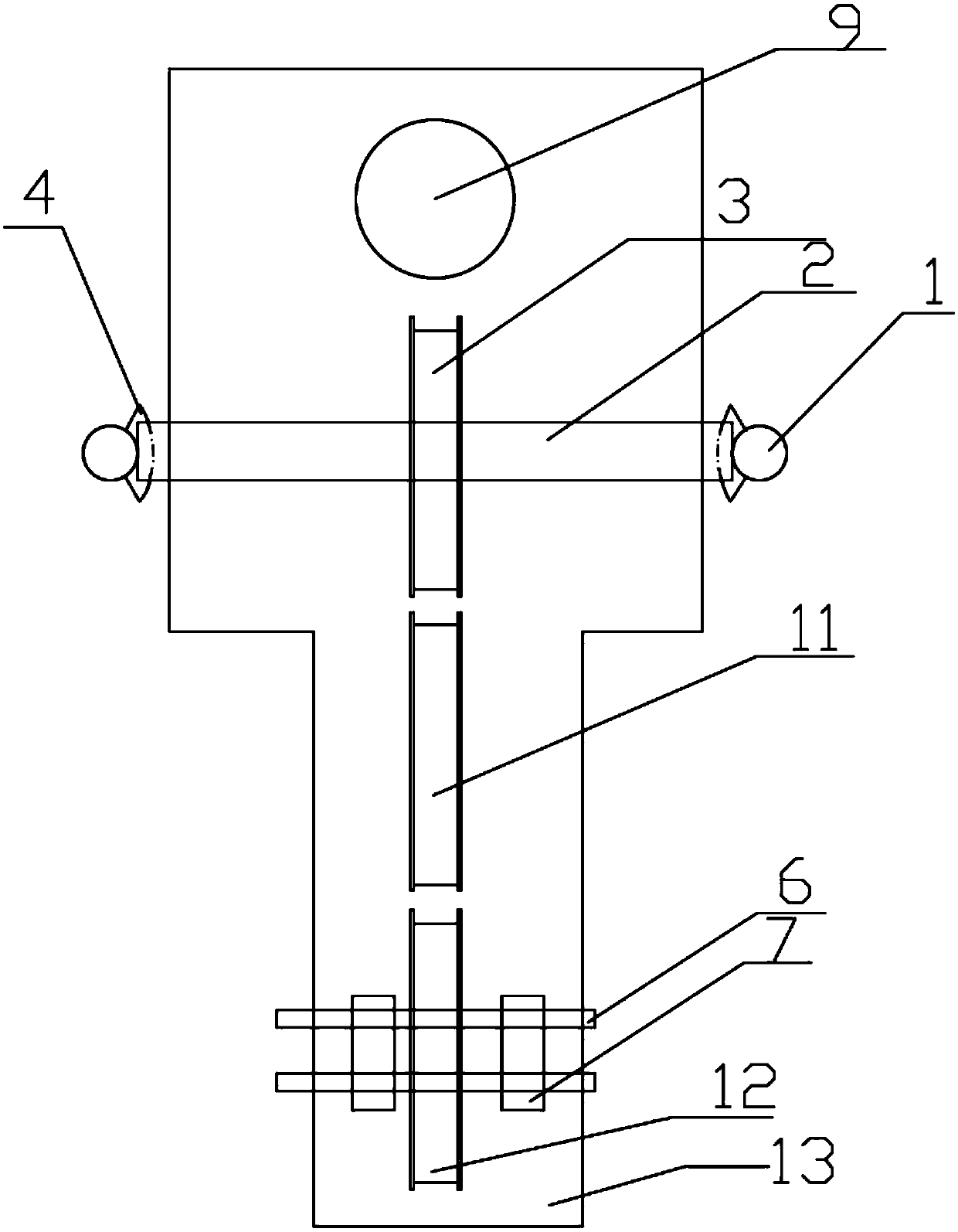

The invention relates to a mounting-free electric hoist energy efficiency test bench. The test bench comprises parallel support legs at intervals, wherein inner sides of two support legs are respectively equipped with supporting plates, the supporting plates are equipped with a main beam, the upper middle portion of the main beam is equipped with an upper pulley, a trolley track arranged on the ground of the side of a hoist is further comprised, the trolley track is equipped with a running bench scale, the running bench scale is equipped with the electric hoist through a wedge block, a lower pulley is mounted at a lower portion of the main beam, a side pulley is mounted at a lower portion of the electric hoist, the side pulley is arranged at one side of the lower pulley, a suspension hookis guided by the electric hoist, a weight assembly mounted in a ground pit is further comprised, and a wire rope penetrates through a suspension hole of the weight assembly and is finally connected with the suspension hook through the suspension hole and sequentially bypassing the upper pulley, the lower pulley and the side pulley. The test bench is advantaged in that the mounting position of theelectric hoist is ingeniously designed, the structure is simplified, the area of the ground pit is small, mounting and dismounting are quite convenient, professional mounting teams are not needed, andwork reliability is greatly improved.

Description

technical field [0001] The invention relates to the technical field of testing devices, in particular to an installation-free electric hoist energy efficiency testing platform. Background technique [0002] At present, the electric hoist test bench is basically a "four-beam four-leg bridge test bench", that is, the test bench is composed of two main beams, two end beams, and four outriggers, and the two end beams are connected by welding or bolts. On the outriggers, the two main beams are placed on the two end beams and fixed with bolts. The upper side of the two main beams is arranged with trolley tracks, and the lower side is welded with I-beams. The four beams and tracks are all supported in the air through the outriggers. . Before the electric hoist test, the trolley electric hoist needs to be hoisted above the main girder by the crane in the test workshop and installed on the rails on the upper side of the two main girders; the suspension type electric hoist needs to b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M99/00

CPCG01M99/005Y02B50/00

Inventor 王松雷邓宏康

Owner SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com