Method for preparing diethyl oxalate by coupling CO

A technology of diethyl oxalate and ethyl nitrite, applied in chemical instruments and methods, carbon monoxide or formate reaction preparation, metal/metal oxide/metal hydroxide catalyst, etc., to achieve high efficiency and good industrialization prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

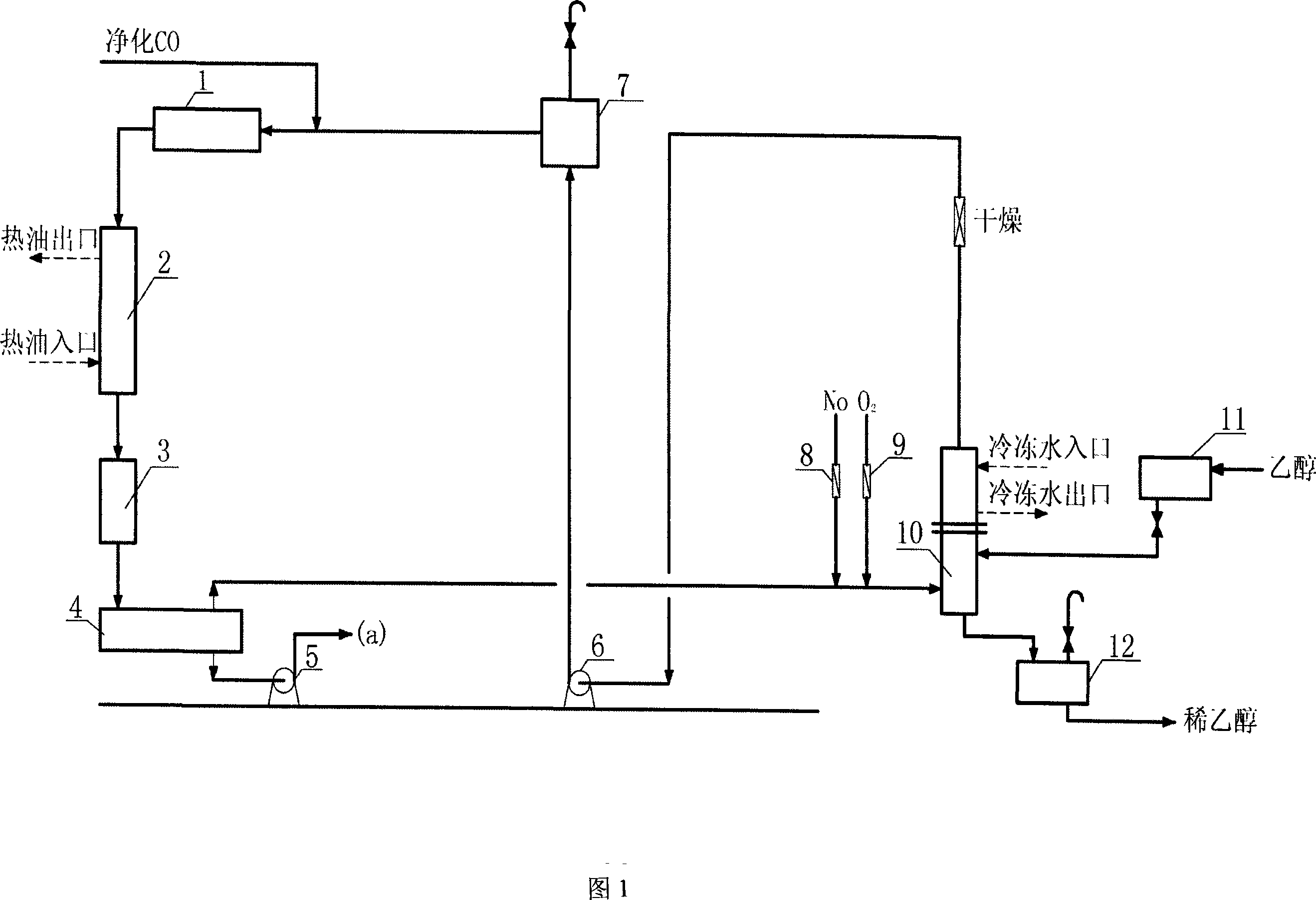

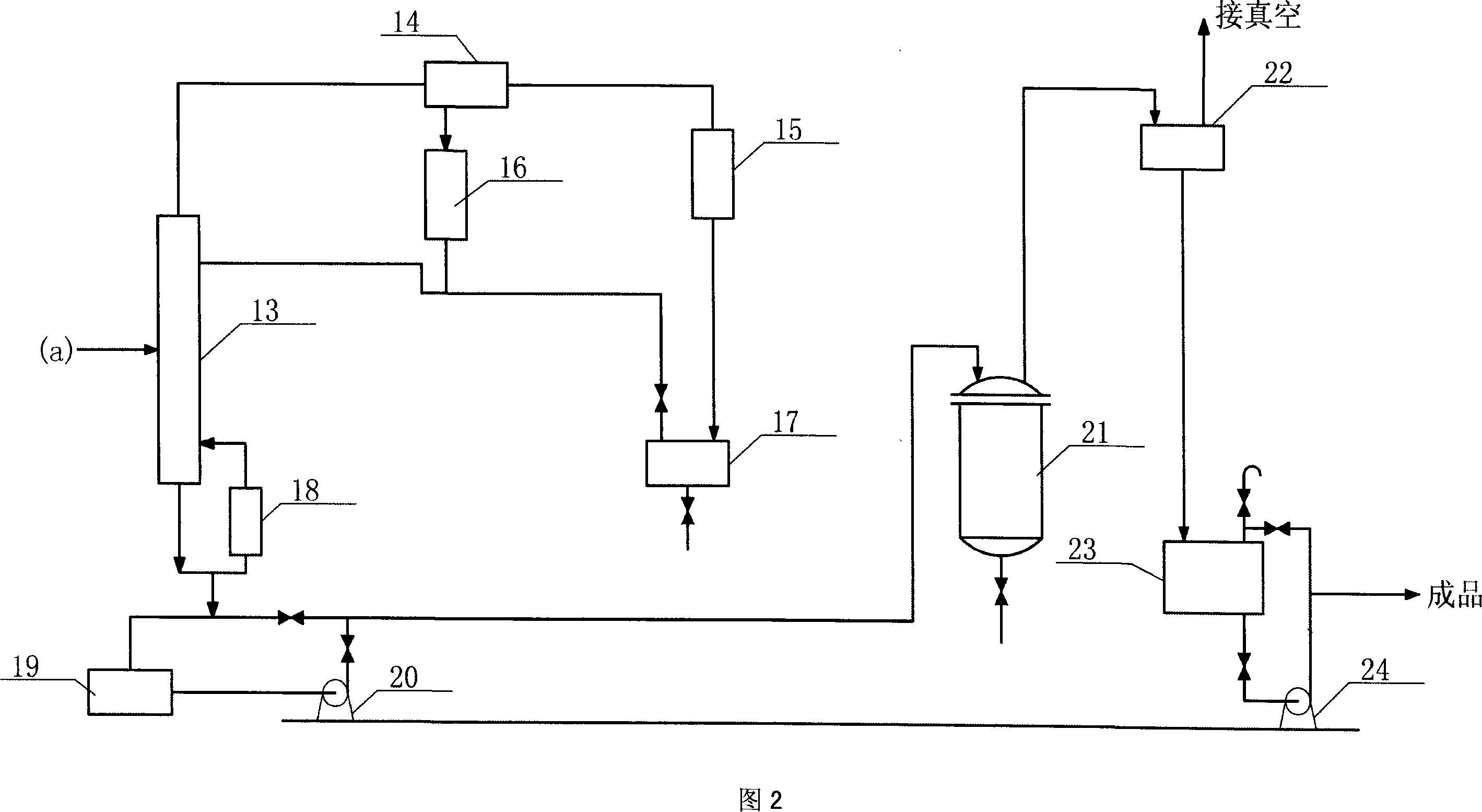

[0035] The CO gas produced by the industrial gas generator is purified and treated to obtain the CO raw material gas composition (volume %) required by the process: CO 96% to 98%, and a small amount of impurities should meet the process requirements. 2 ≤100ppm, S≤1ppm, H 2 O≤100ppm, H 2 ≤100ppm, the rest is N 2 gas. The CO purified feed gas enters the reaction system with an operating pressure (gauge pressure) of 0.12MPa-0.2MPa (see Figure 1 for the device). The flow rate of CO raw material gas is 170L / h and the ethyl nitrite cycle gas from the cycle gas storage tank 7 enters the preheater 1 for mixing and preheating (60°C-70°C), and then enters the coupling reactor 2 after preheating. The coupling reactor is a fixed-bed tubular reactor, 3 meters long, a stainless steel jacketed reactor with a diameter of Φ32×2.5 mm, and 1 kg of Pd-Fe / Al is placed in the tube 2 o 3 For bimetallic supported catalysts, the temperature of the reaction bed is adjusted by circulating hot oil i...

Embodiment 2

[0041] The CO gas produced by the industrial gas generator is purified by water washing, alkali washing, desulfurization, deoxidation, and drying. 2 ≤100ppm, S≤lppm, H 2 O≤100ppm, H 2 ≤100ppm, the rest is N 2 gas. The CO cleans the feed gas to 16M 3 The feed flow rate of / h enters the reaction system (see Figure 1 for the device). The process operating pressure (gauge pressure) is 0.16MPa~0.2MPa. The feed gas is mixed with the ethyl nitrite recycle gas obtained from the regeneration reaction in the recycle gas storage tank 7 in a ratio of 8 to 10:1 (the recycle ratio is the ratio of the feed volume of the recycle gas to the feed gas) ratio) into the preheater 1 together, and the mixed gas enters the coupling reactor 2 after preheating. The coupling reactor is a fixed bed tubular reactor, and there are 96 tubes in total, each tube is 3 meters long and has a diameter of Φ32×2.5mm stainless steel tubes, 1.25kg of catalyst is placed in each tube, and the reactor is filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com