Intelligent aggregate proportioning platform scale

A technology of intelligent aggregate and platform scale, which is applied in the field of aggregate proportioning, can solve problems such as inability to combine proportioning, and achieve the effect of shortening the proportioning cycle and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

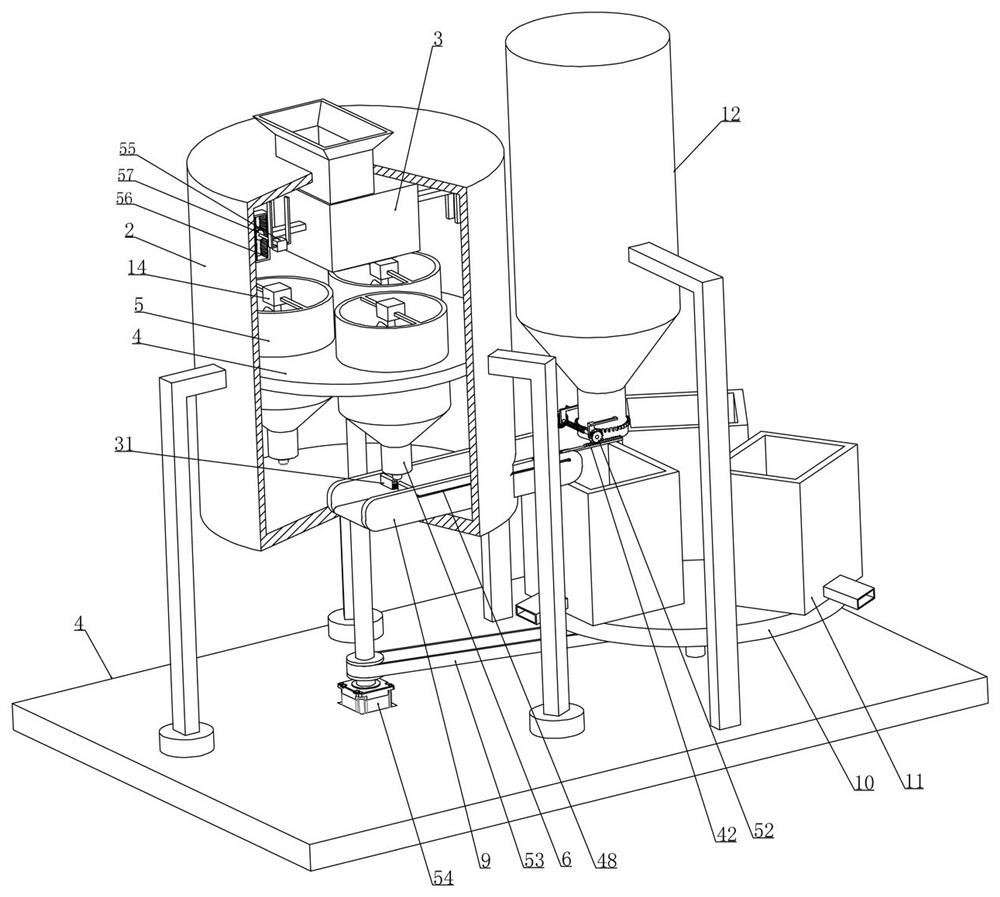

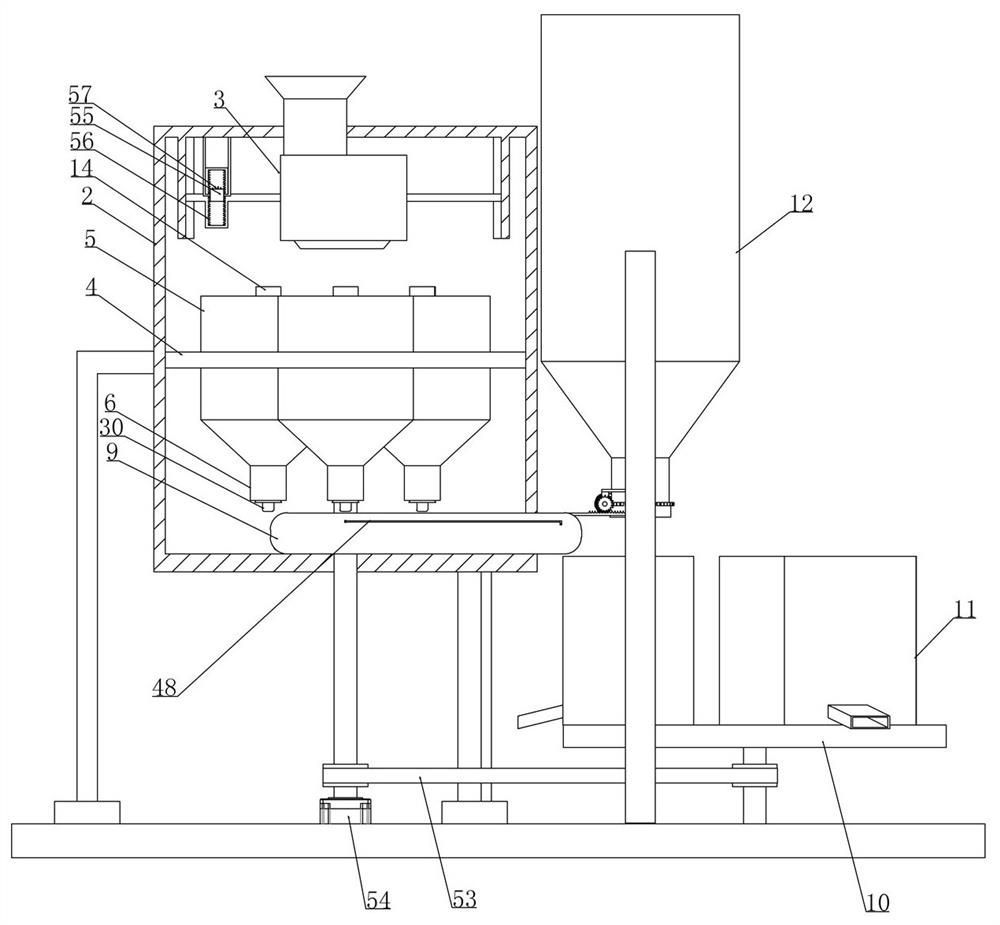

[0044] Embodiment 1, this embodiment provides an intelligent aggregate proportioning platform scale, refer to the attached figure 1 As shown, a mounting base 1 is included and a collecting tube 2 is fixedly arranged on the mounting base 1. It is characterized in that a screening cavity 3 is installed on the upper end of the collecting tube 2, and the collecting tube 2 is located below the screening cavity 3 to rotate. A loading plate 4 is installed and a number of storage boxes 5 are fixedly installed at intervals on the loading plate 4. The screening chamber 3 can be used to screen aggregates of different particle sizes mixed together and aggregate the aggregates in our required particle size range. The material is stored in the corresponding material storage box 5, and the bottom of the screening chamber 3 is provided with a leak hole 51, and a discharge device is installed at intervals below the leak hole 51 in the collection cylinder 2, and the discharge device will dischar...

Embodiment 2

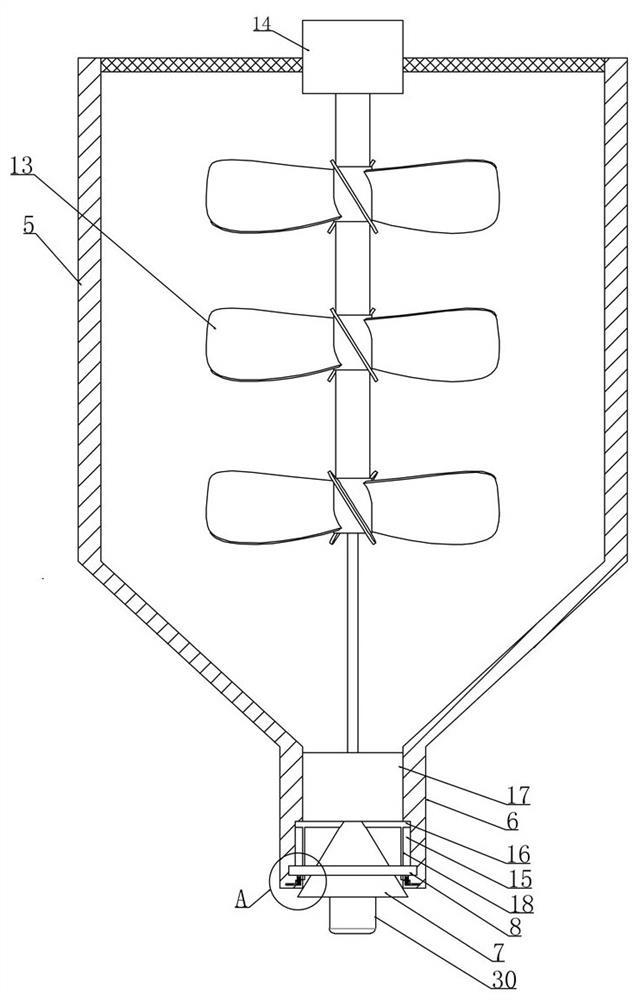

[0050] Embodiment 2, on the basis of embodiment 1, with reference to appended image 3 As shown, the unloading device is a unloading roller 13 coaxially rotated and installed in the storage box 5, and the bottom of the unloading roller 13 is threaded with the tapered valve 7, and the unloading roller 13 is fixed by Driven by the blanking motor 14 on the top of the material storage box 5 (in this scheme, the motor controller of each blanking motor 14 is electrically connected with the micro-control processor, when the belt scale 9 detects that the material storage box 5 is discharged When the aggregate reaches the set value, the micro-control processor controls the corresponding working blanking motor 14 to reverse), and when the blanking motor 14 drives the blanking roller 13 to rotate, the aggregate in the storage box 5 is The trend of downward movement, see attached Figure 6 As shown, there are vertically extending chutes 15 on both sides of the inner axis of the lower mat...

Embodiment 3

[0051] Embodiment 3, on the basis of embodiment 2, with reference to appended Figure 4 , 7 As shown, the coaxial center of the lower material barrel 6 is provided with an annular cavity 19 that communicates with the chute 15 and is rotatably fitted with the annular ring 8. The vertical length of 15 is set in steps (that is, the top heights of chute 15 in different lower barrels 6 are the same, but the heights of the bottom ends of chute 15 in different lower barrels 6 are different, so the circular rings in different lower barrels 6 circle 8 is located at different heights), refer to the attached Figure 5 , 7 As shown, the axial sides of the annular ring 8 are provided with limit holes 20 matched with the chute 15, and the tapered valve 7 drives the slide rod 16 fixedly connected with it to move to the limit hole 20 under the drive of the blanking motor 14. At the upper end face, the annular ring 8 is in the positioning state under the action of the positioning block 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com