Water-soluble corrosion inhibitor, preparation and application thereof

A corrosion inhibitor, water-soluble technology, used in the treatment of equipment corrosion/fouling inhibition, petroleum industry, hydrocarbon oil treatment, etc., can solve the problem of narrow use range, and achieve low cost, good water solubility, low toxicity and no odor on site effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

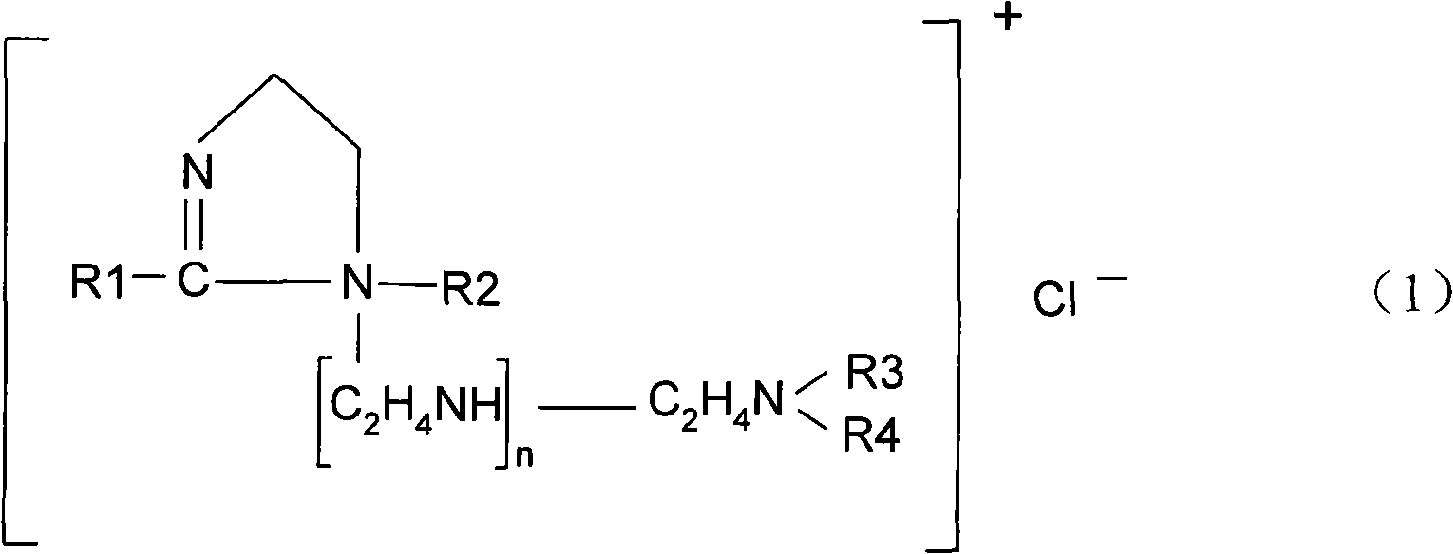

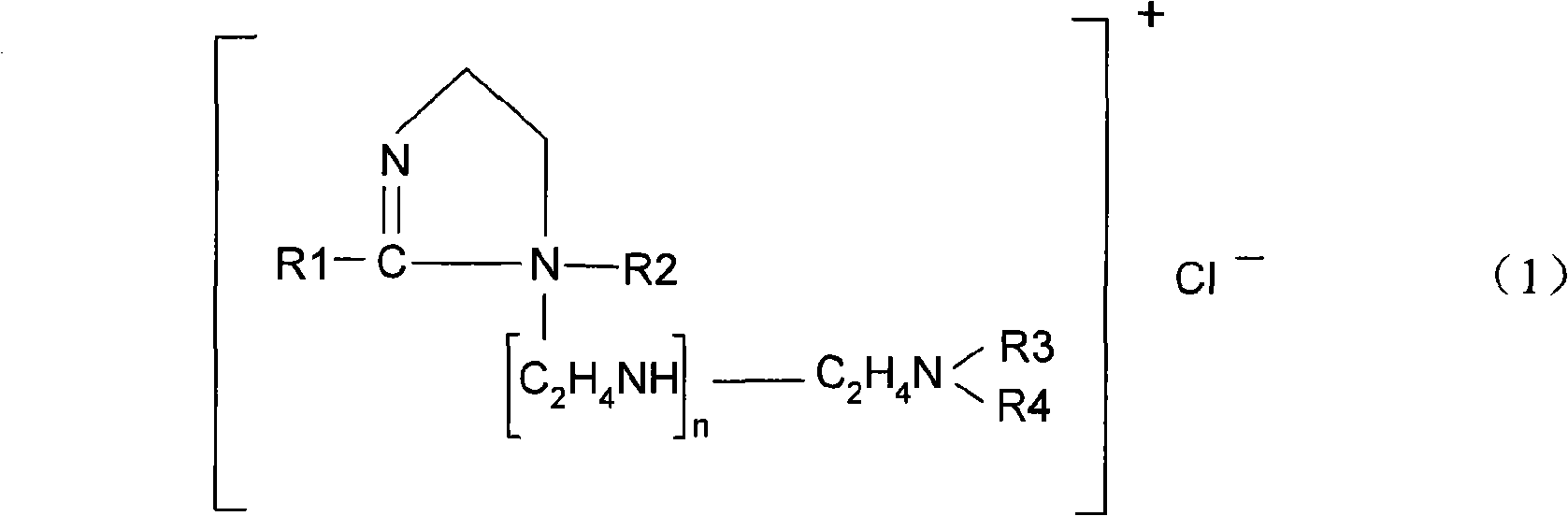

Method used

Image

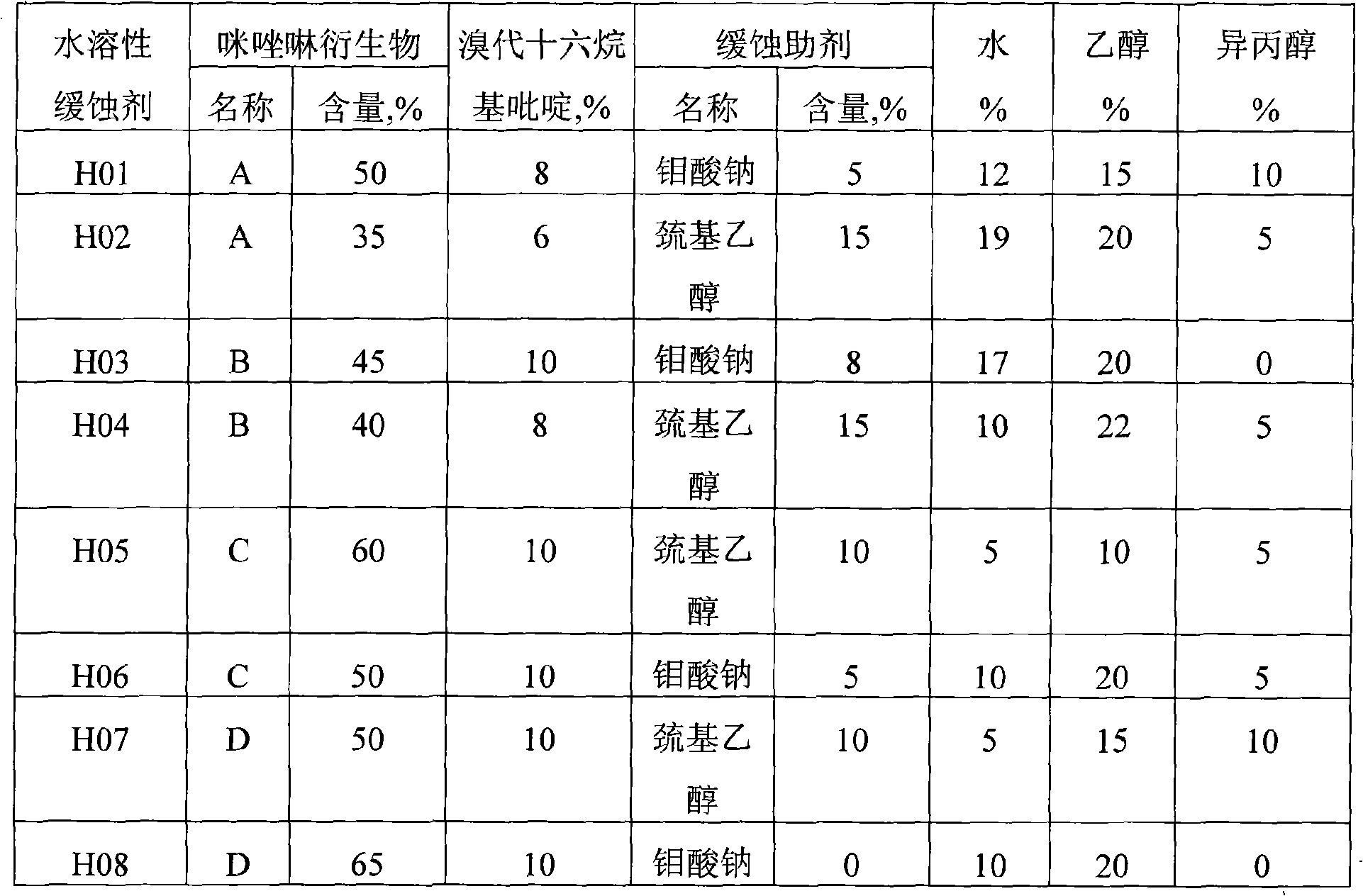

Examples

Embodiment 1

[0042] Put oleic acid and diethylenetriamine into the reactor according to the molar ratio of 1:1.1, add boric acid accounting for 0.2% by weight of the feeding amount, gradually raise the temperature to 230° C. under constant stirring, and the temperature rise reaction time is 4 hours to obtain the imidazoline intermediate . Then the imidazoline intermediate and thiourea are added to the reactor according to the molar ratio of 1:1, and 15% by weight of n-hexanol accounting for the total weight of the imidazoline intermediate and thiourea is added, and the reaction is carried out at a temperature of 140 to 170° C. for 3 hours After cooling to below 60°C, slowly add benzyl chloride reagent according to the molar ratio of 1:1.5, react at 90-110°C for 3 hours after the addition, and obtain a brown imidazoline derivative A after cooling.

Embodiment 2

[0044] According to the method similar to the preparation of imidazoline derivative A in Example 1, triethylenetetramine was used instead of diethylenetriamine to prepare imidazoline derivative B.

Embodiment 3

[0046] According to the method similar to the preparation of imidazoline derivative A in Example 1, oleic acid was replaced by linoleic acid to prepare imidazoline derivative C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com