Preparation method and application of plant acid pickling corrosion inhibitor

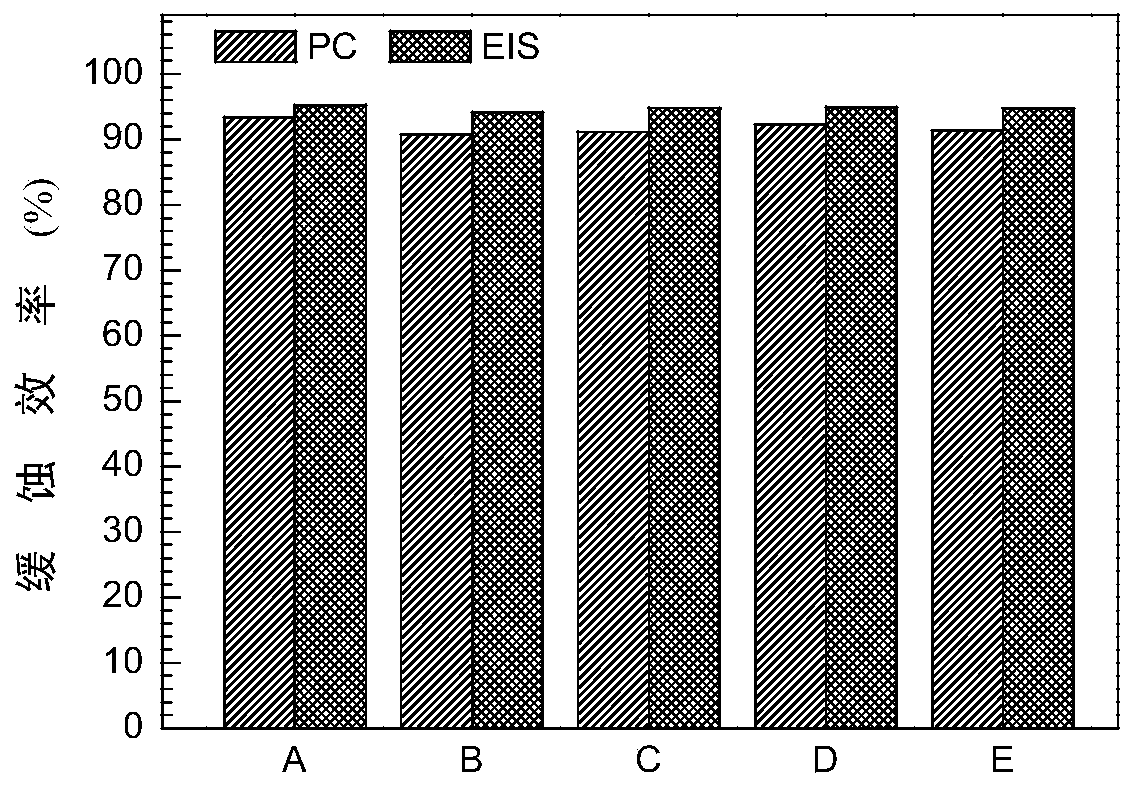

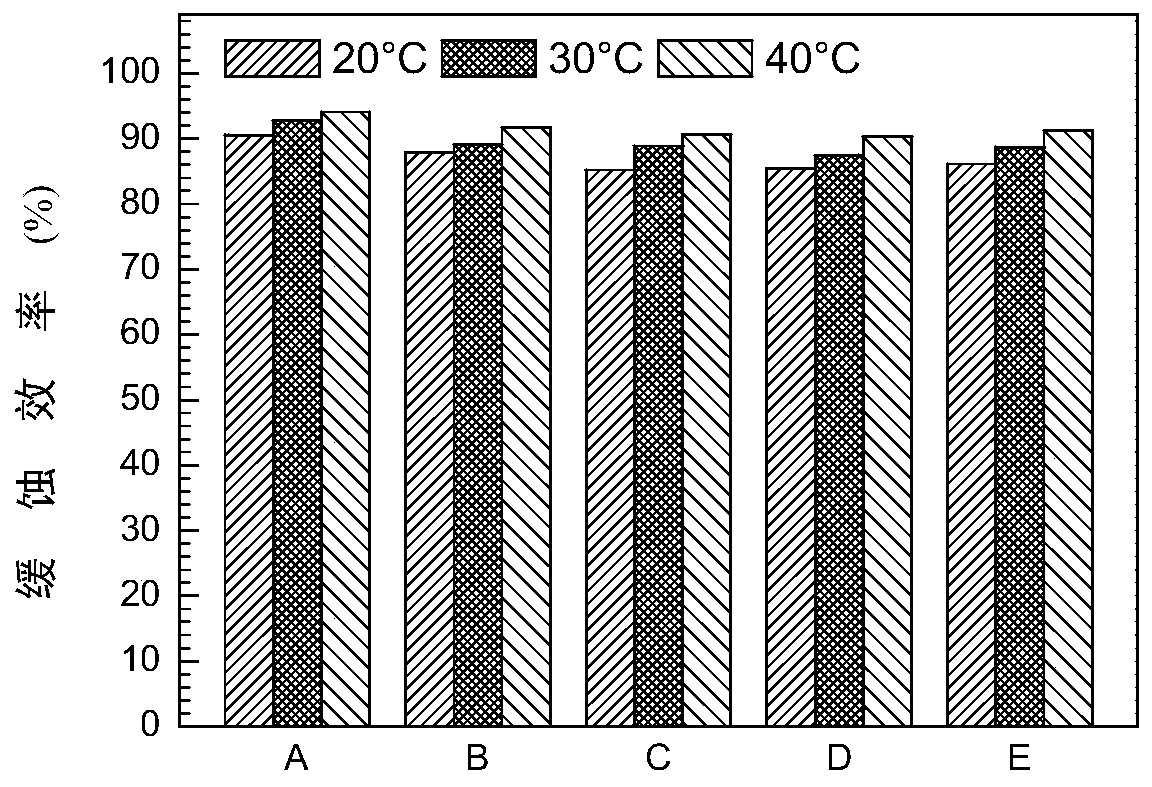

A technology of corrosion inhibitor and plant acid, which is applied in the field of preparation of plant pickling corrosion inhibitor, can solve the problems of using organic solvents, aqueous solutions containing organic solvents or organic acid solutions, waste of resources, harmful environment, etc., and achieve production costs Low, high corrosion inhibition efficiency, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

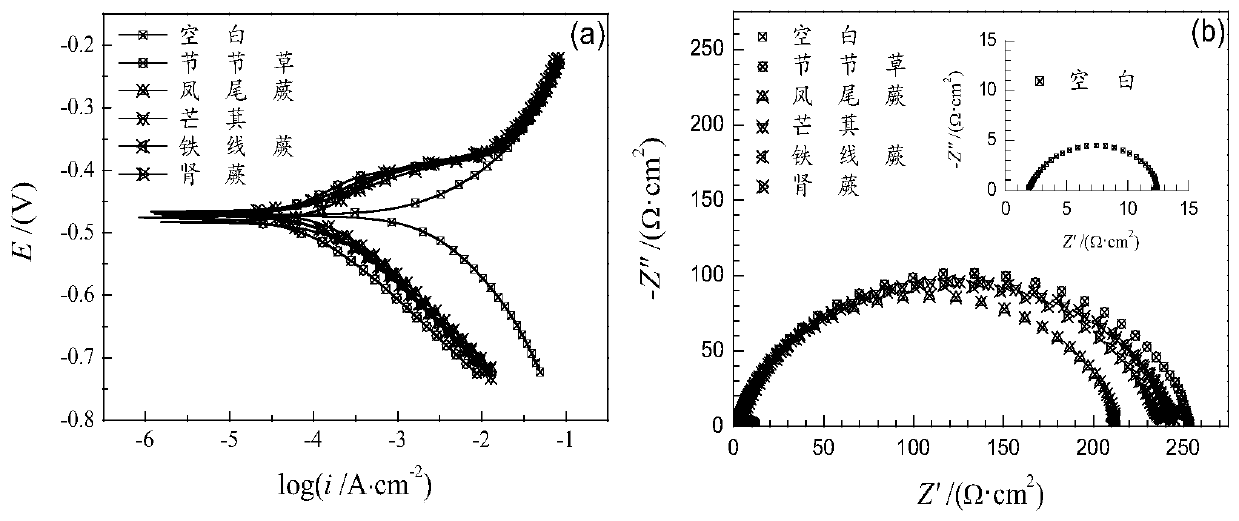

Examples

Embodiment 1

[0030] Example 1 Extraction method of oxalic pickling corrosion inhibitor

[0031] S1 Picking the syringa in Zixi Mountain, Chuxiong, Yunnan, washing the syringa, drying in the sun or in a drying oven, crushing and passing through a 100-mesh sieve to obtain plant powder.

[0032] S2 uses distilled water as the extraction solution, according to the material-liquid ratio of 1:19, placed in an ultrasonic instrument at 50°C for 45 minutes, and then vacuum-filtered; Sonicate in an ultrasonic instrument for 30 minutes, vacuum filter, and combine the two filtrates to obtain a crude extract solution.

[0033] The S3 crude extract solution was cooled to room temperature, extracted twice with petroleum ether (volume ratio 1:1) to remove a small amount of lipids; the extracted stock solution was rotary evaporated to about 1 / 3 of the original volume, and the concentrated extract Add absolute ethanol, the volume ratio of ethanol to extract (1.5-2): 1, remove impurities such as polysacchar...

Embodiment 2

[0039] Example 2 Pteris fern pickling corrosion inhibitor extraction method

[0040] S1 Pteris fern is picked from Zixi Mountain in Chuxiong, Yunnan Province. The fern is picked and washed, dried in the sun or dried in a drying oven, crushed and sieved through a 100-mesh sieve to obtain plant powder.

[0041] S2 uses distilled water as the extraction solution, according to the material-to-liquid ratio of 1:15, placed in an ultrasonic instrument at 50°C for 30 minutes, and then vacuum-filtered; Sonicate in an ultrasonic instrument for 30 minutes, vacuum filter, and combine the two filtrates to obtain a crude extract solution.

[0042]S3 crude extract solution is cooled to room temperature, extracts 2 times with sherwood oil (volume ratio 1: 1) to remove a small amount of lipid substance; After extracting, the stock solution is rotary evaporated to 1 / 3 of the original volume, to the concentrated extract Add absolute ethanol to the mixture, the volume ratio of ethanol to the ext...

Embodiment 3

[0048] Example 3 Osmanthus pickling corrosion inhibitor extraction method

[0049] S1 Osmanthus japonica is picked in Zixi Mountain, Chuxiong, Yunnan Province. After picking Osmanthus osmanthus, wash, dry in the sun or in a drying oven, crush and sieve through a 100-mesh sieve to obtain plant powder.

[0050] S2 uses distilled water as the extraction solution, according to the material-liquid ratio of 1:20, placed in an ultrasonic instrument at 50°C for 45 minutes, and vacuum filtration; the obtained filter residue is added with distilled water according to the material-liquid ratio of 1:20, placed Sonicate in an ultrasonic instrument for 30 minutes, vacuum filter, and combine the two filtrates to obtain a crude extract solution.

[0051] S3 crude extract solution is cooled to room temperature, extracts 2 times with sherwood oil (volume ratio 1: 1) to remove a small amount of lipid substance; After extracting, the stock solution is rotary evaporated to 1 / 3 of the original volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com