Aqueous surface treatment for environment-friendly precoated metal materials, surface-treated metal materials, and environment-friendly precoated metal materials

A technology of surface treatment agent and metal material, which is applied in the direction of metal material coating process, anti-corrosion coating, metal layered products, etc., can solve the problem that the coating adhesion of pre-coated steel plate cannot be satisfied, and achieve coin scratch resistance Excellent, excellent effect of alkali resistance and acid resistance

Inactive Publication Date: 2009-09-23

NIHON PARKERIZING

View PDF7 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, even with this technology, the paint adhesion of pre-coated steel sheets cannot be satisfied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

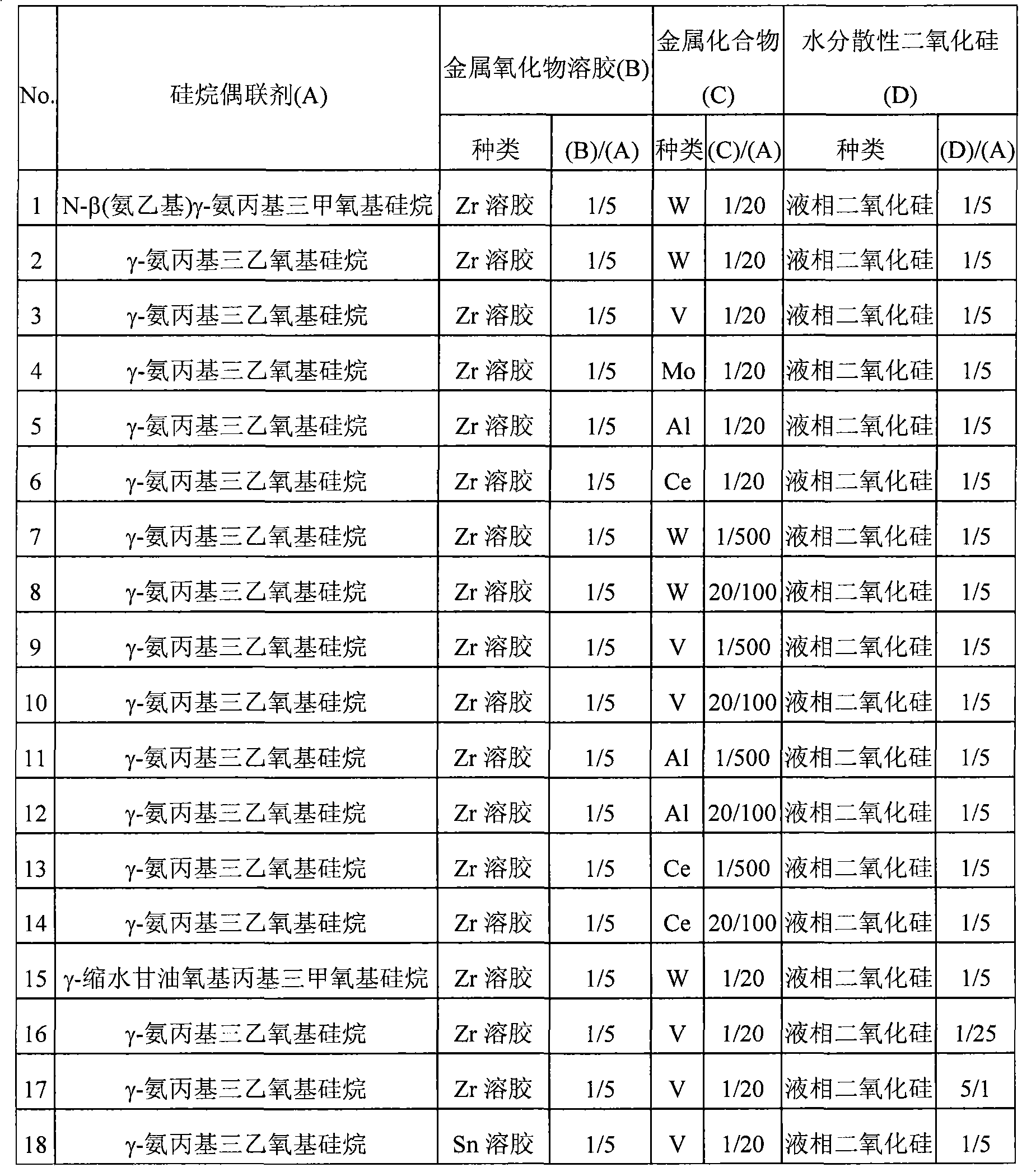

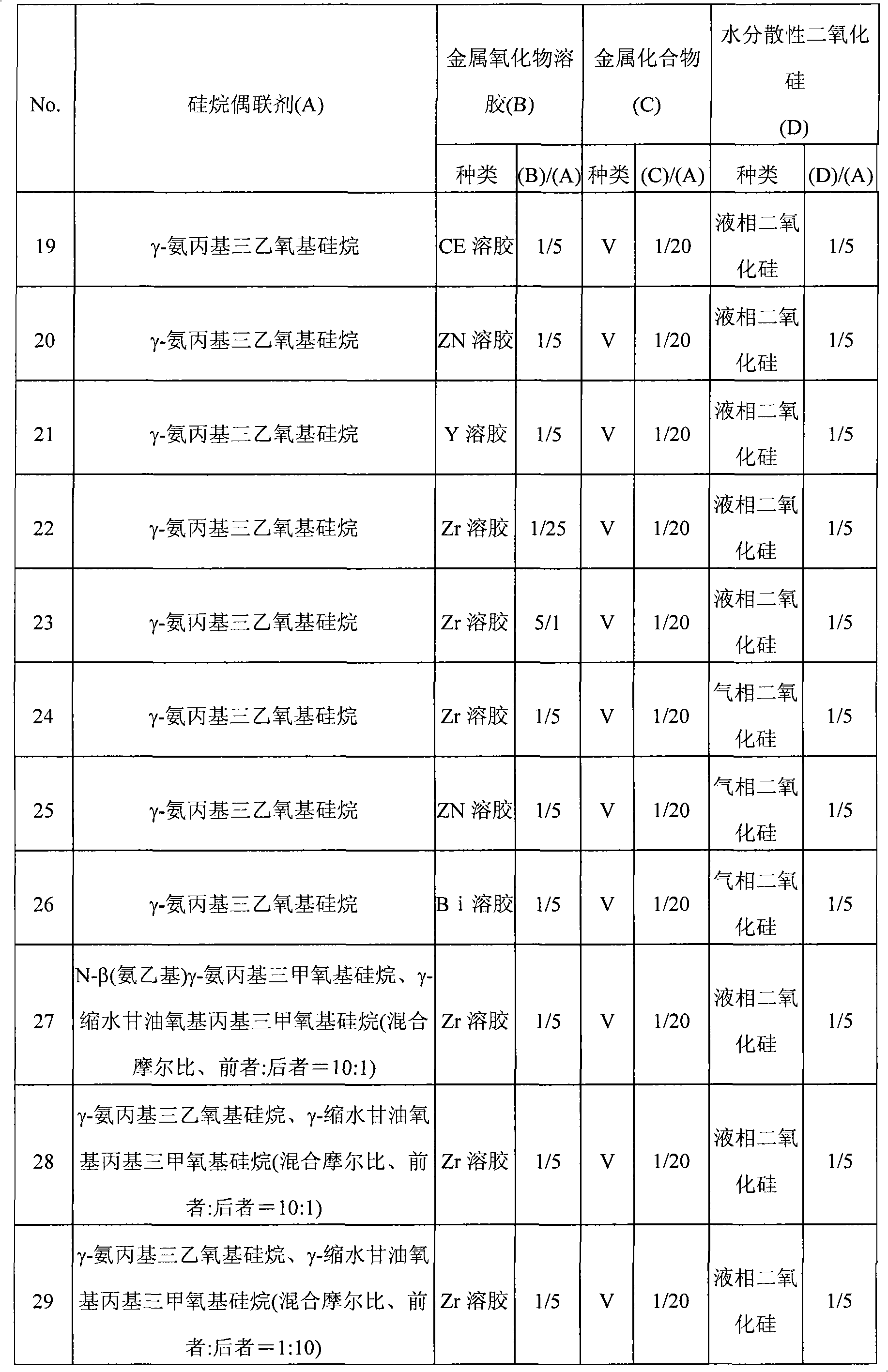

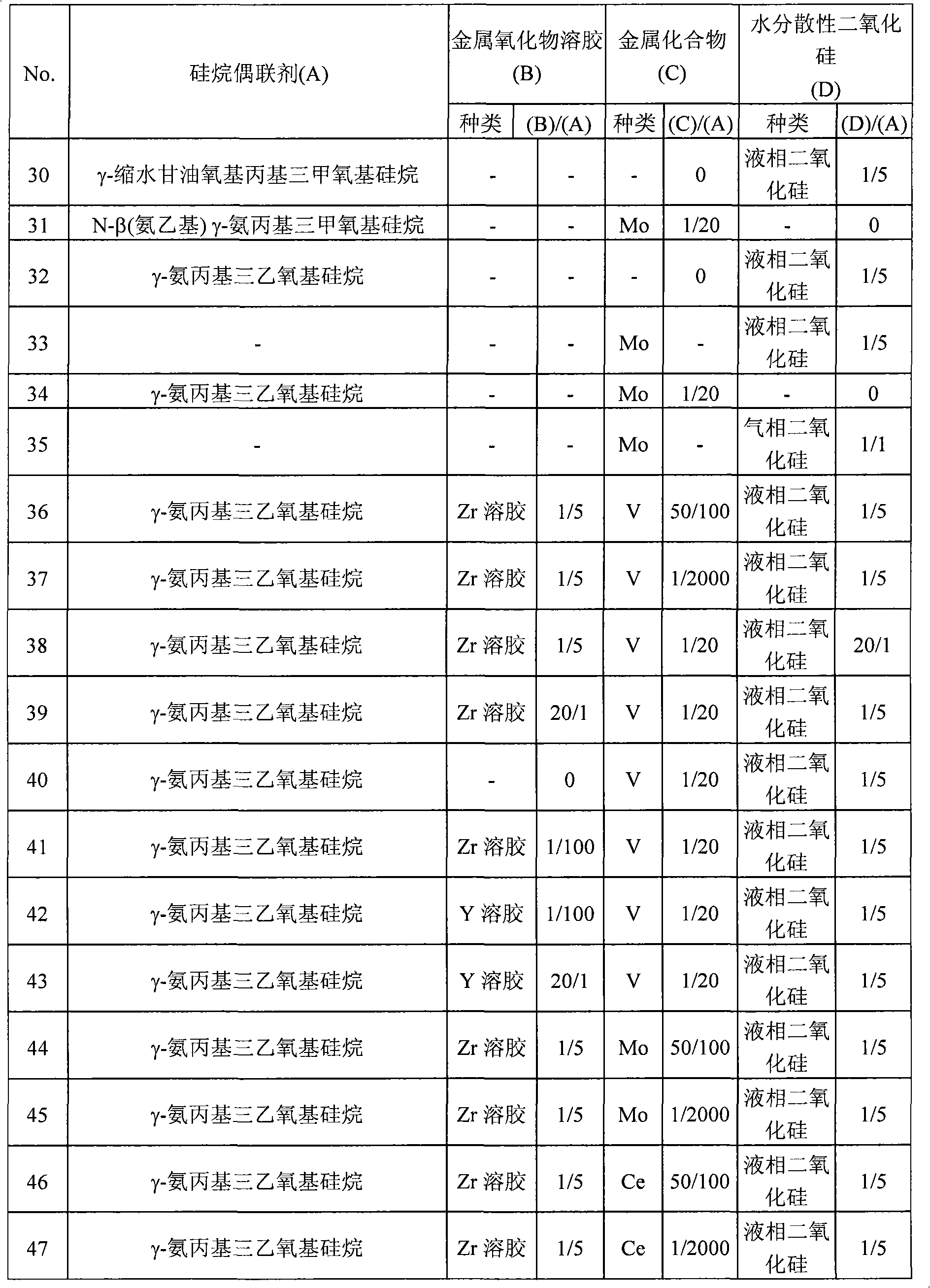

Embodiment 1~33、 comparative example 1~18

[0087] Select the test material as shown in Tables 4 to 6, and use a roller coater to apply the surface treatment agent of the composition shown in Tables 1 to 3 to the surface of the pretreated test material (one side), so that the dry coating amount is 0.1g / m 2 , and dried in a hot air drying oven under the condition that the board reaches a temperature of 80°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a chromium-free aqueous surface treatment useful as primer in producing precoated metal materials which are excellent in corrosion resistance, tight adhesion of coat (primary adhesiveness and secondary adhesiveness of coat in T-bend test), and coin scratch resistance. An aqueous surface treatment for environment-friendly precoated metal materials which contains (A) a silane coupling agent and / or a condensate of a silane coupling agent, (B) a metal oxide sol, (C) a metal compound, and (D) water-dispersible silica, wherein the metal compound (C) is at least one member selected from among compounds of V, W, Mo, Al, Sn, Nb, Hf, Y, Ho, Bi, La, Ce and Zn, and the (B) / (A) mass ratio is 1 / 50 to 10 / 1, the (C) / (A) mass ratio is 1 / 1000 to 4 / 10, and the (D) / (A) mass ratio is 1 / 50 to 10 / 1; and metal materials and chromium-free precoated metal materials, which have films made from the surface treatment.

Description

technical field [0001] The present invention relates to a chromium-free water-based surface treatment agent useful as a base treatment agent for producing a precoated metal material excellent in paint adhesion, corrosion resistance, and coin scratch resistance, and a surface treated metal material and an environment-friendly precoat Painted metal material. Background technique [0002] For components such as home appliances, building materials, and automobiles, conventional post-coating products that are painted after processing are often pre-treated with phosphate, etc. However, in recent years, especially in home appliances, coatings have begun to be used. A pre-coated metal sheet with a colored organic film is used instead of this pre-treatment. This metal plate is coated with an organic film on a surface-treated metal plate or a plated metal plate, and has the characteristics of being good in processability and good in corrosion resistance while being aesthetically plea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C22/00B32B15/08C09D1/00C09D5/08C09D7/12

CPCC23C2222/20C09D1/00C09D5/08B32B15/08C23C22/00

Inventor 猪古智洋野村信治山本茂树

Owner NIHON PARKERIZING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com