Green sodium alginate corrosion inhibitor for carbon steel neutral medium and application thereof

The technology of sodium alginate and neutral medium is applied in the field of corrosion inhibitor for neutral medium of green sodium alginate carbon steel, which can solve the problems of toxic and side effects, poor environmental friendliness, etc. Low dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Immerse the packaged carbon steel electrode with the neutral medium NaCl solution added with the corrosion inhibitor sodium alginate for 0.5h at room temperature; the amount of the corrosion inhibitor added to each liter of the neutral medium NaCl solution is 0.5g, neutral Medium NaCl solution, the mass concentration is 3.5%. Sodium alginate Mw is 50000.

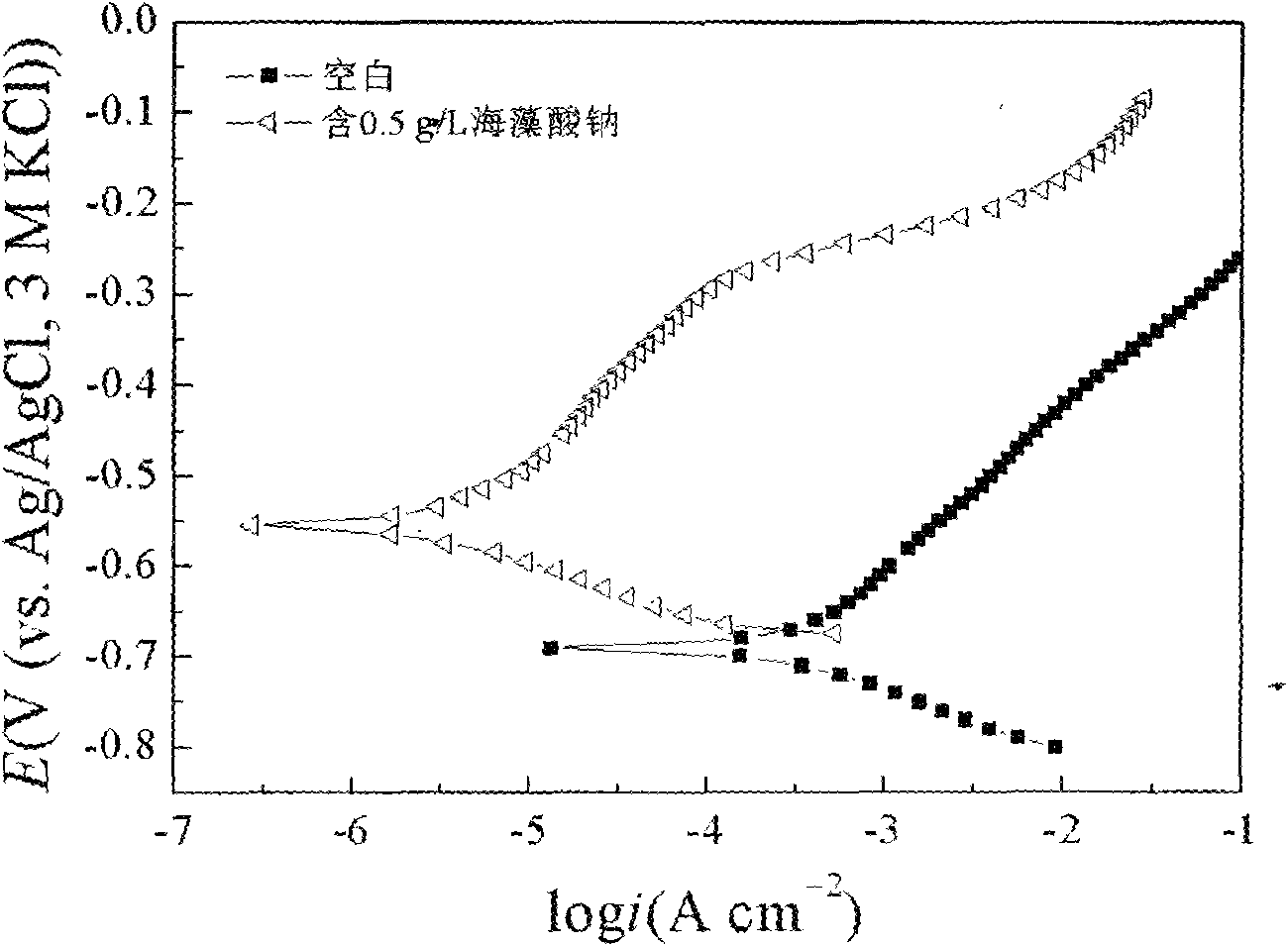

[0016] The corrosion inhibition efficiency obtained by the Tafel polarization curve test (see figure 1 ):

[0017] A carbon steel electrode was used as the working electrode, using Epoxy resin package, electrode exposure area 0.196cm 2 , platinum wire electrode as auxiliary electrode, silver / silver chloride (Ag / AgCl, 3M KCl) electrode as reference electrode, NaCl solution as electrolyte, assembled into a three-electrode test system. Using the 760C electrochemical workstation of CHI Company of the United States to carry out the Tafel polarization curve test, the test potential is -300 to 300mV (vs.E oc )(E oc is...

Embodiment 2

[0022] Immerse the packaged carbon steel electrode with the neutral medium NaCl solution added with the corrosion inhibitor sodium alginate for 2 hours at room temperature; the amount of the corrosion inhibitor added to each liter of the neutral medium NaCl solution is 0.06g, and the neutral medium NaCl solution, the mass concentration is 4%. The Mw of sodium alginate is 100000.

[0023] The corrosion inhibition efficiency obtained by the Tafel polarization curve test is greater than 80%, showing that it is an efficient corrosion inhibitor.

Embodiment 3

[0025] Immerse the packaged carbon steel electrode with the neutral medium NaCl solution added with the corrosion inhibitor sodium alginate for 2 hours at room temperature; the amount of the corrosion inhibitor added to each liter of the neutral medium NaCl solution is 1.00g, and the neutral medium NaCl solution, the mass concentration is 3.0%. Sodium alginate Mw is 20000.

[0026] The corrosion inhibition efficiency obtained by the Tafel polarization curve test is greater than 90%, showing that it is an efficient corrosion inhibitor.

[0027] The neutral solution is NaCl solution, the mass concentration is 3.0%, the dosage is 1L, sodium alginate (Mw=20000) 1.00g is added, and the packaged carbon steel electrode is immersed in the 3.0% NaCl solution for 4 hours at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com