Preparation method of high-temperature corrosion inhibitor for inhibiting petroleum acid corrosion

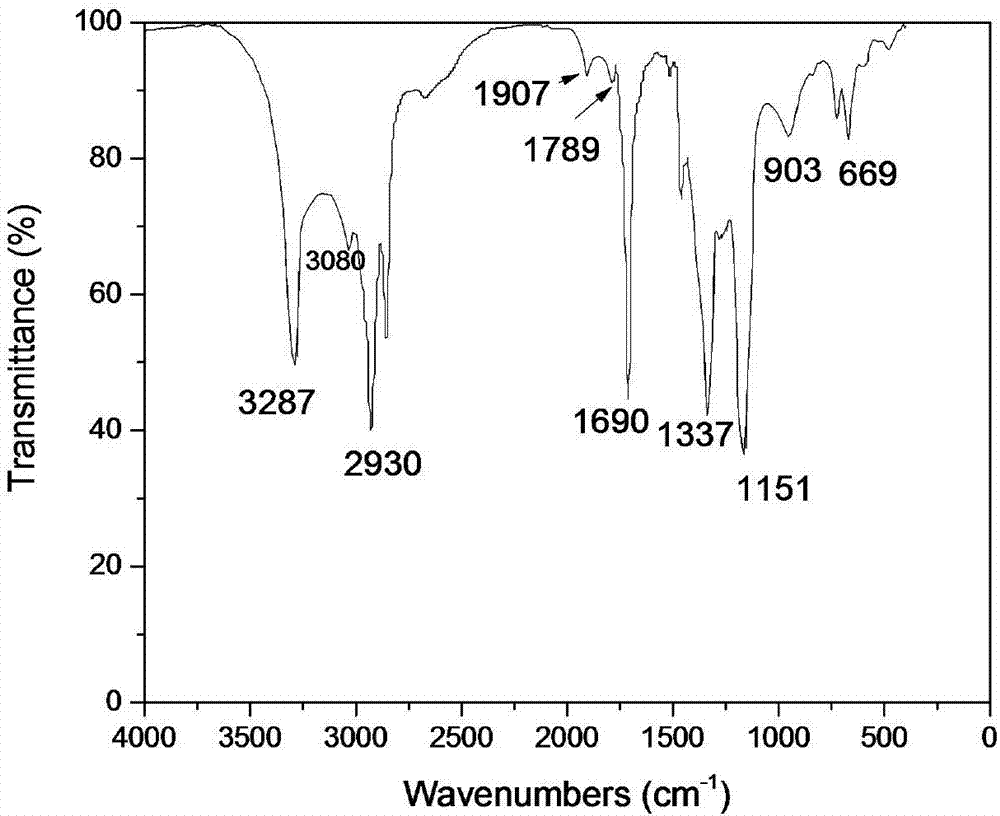

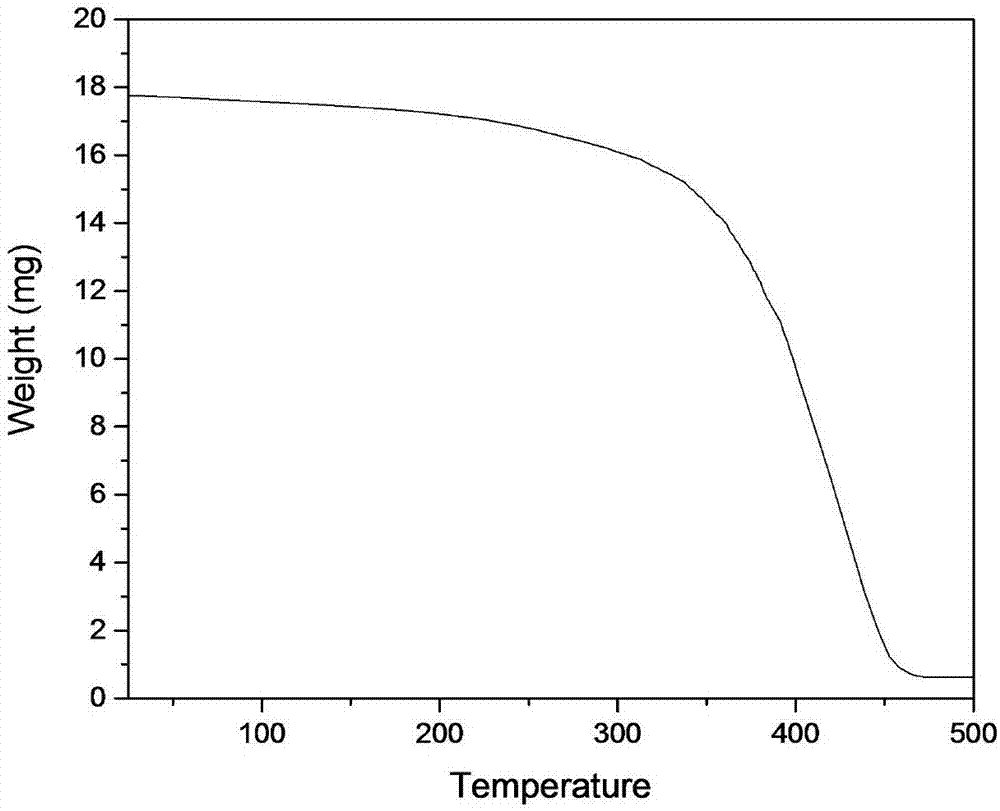

A technology of high-temperature corrosion inhibitor and petroleum acid, which is applied in the preparation of sulfonic acid, carboxylic acid amide, and organic compound, can solve the problems of difficult degradation, human and environmental hazards, and unsatisfactory corrosion inhibition effect High corrosion efficiency and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

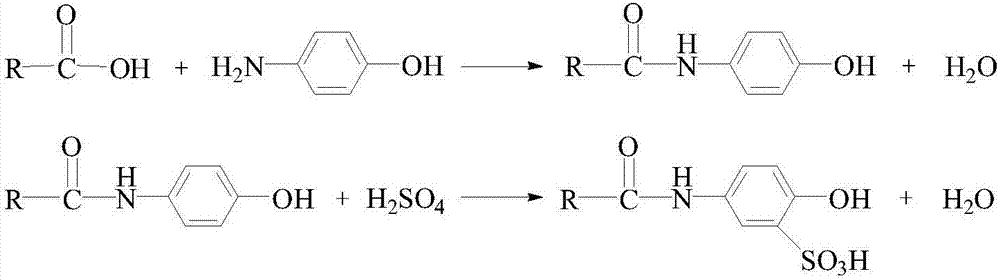

[0017] Embodiment 1, a kind of preparation method that suppresses petroleum acid corrosion high temperature corrosion inhibitor, comprises the following steps:

[0018] Step 1) Weigh 10g of p-aminophenol and dissolve it in 80g of dimethylformamide (DMF) solution, heat to 60°C, add 25g of tall oil fatty acid dropwise under stirring, after the dropwise addition is completed, heat up to 80°C, Continue to stir and react for 3 hours, then raise the temperature to 170°C, and separate the generated water from the water separator by reflux; cool down to 95°C after anhydrous distillation, and use a rotary evaporator to remove the solvent dimethyl in the product under reduced pressure Dimethylformamide (DMF) to obtain a yellow viscous liquid alkylamidophenol;

[0019] Step 2) Add 10 g of concentrated sulfuric acid with a mass fraction of 98% to the alkylamidophenol, control the reaction temperature at 70°C for 3 hours to generate ammonium sulfate, add 12 g of potassium hydroxide solid a...

Embodiment 2

[0020] Embodiment 2, a kind of preparation method that suppresses petroleum acid corrosion high-temperature corrosion inhibitor, comprises the following steps:

[0021] Step 1) Weigh 13g of p-aminophenol and dissolve it in 80g of dimethylformamide (DMF) solution, heat to 60°C, add 32.5g of tall oil fatty acid dropwise under stirring, after the dropwise addition, heat up to 80°C ℃, continue to stir the reaction for 3 hours, then raise the temperature to 180 ℃, and separate the generated water from the water separator by reflux; cool down to 90 ℃ after anhydrous distillation, and use a rotary evaporator to remove the solvent in the product under reduced pressure Dimethylformamide (DMF) gives yellow viscous liquid alkylamidophenol;

[0022] Step 2) Adding 13g of concentrated sulfuric acid with a mass fraction of 98% to the alkylamidophenol, controlling the reaction temperature at 70-75°C for 2-3 hours to generate ammonium sulfate, adding 15.6g of potassium hydroxide solid after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com