Water-soluble imidazoline amide corrosion inhibitor, preparation method thereof and using method thereof

An imidazoline amide, water-soluble technology, applied in the corrosion inhibitor field of oil refining process, can solve the problems of increased risk, high cost, unfavorable neutralizer addition, etc., and achieve the effect of corrosion inhibition, low cost and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

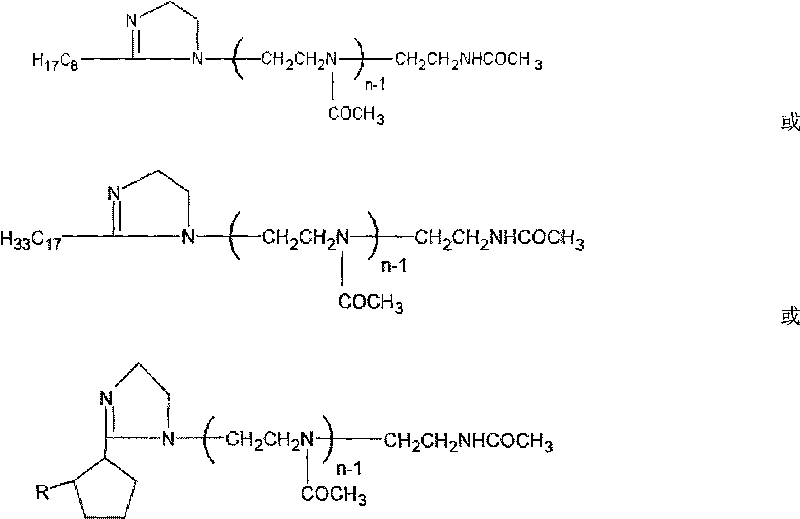

Method used

Image

Examples

Embodiment 1

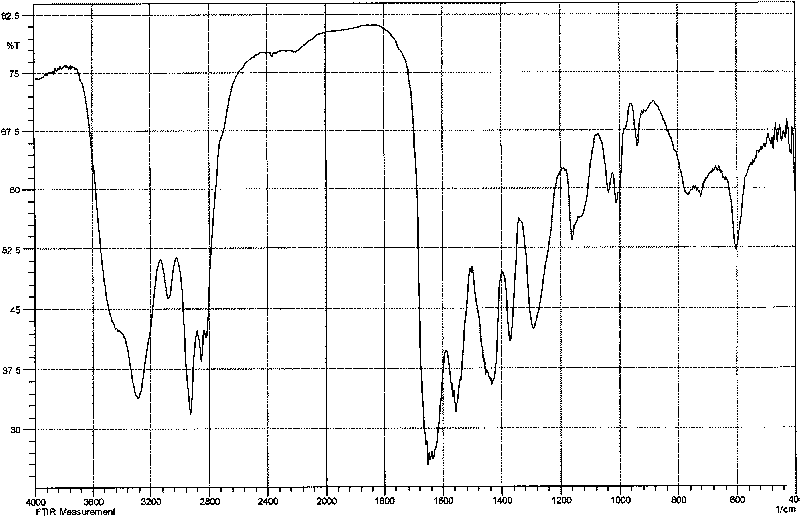

[0042] The process steps for the preparation of the water-soluble imidazoline amide corrosion inhibitor are as follows.

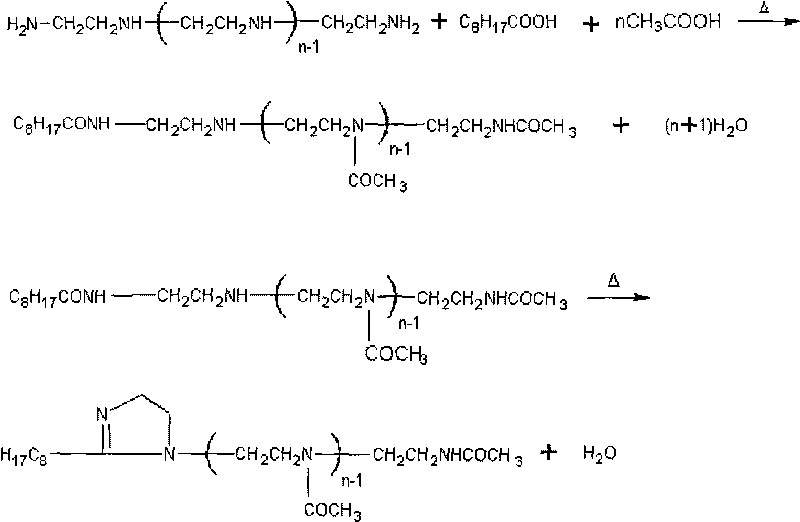

[0043] (1) Synthesis of water-soluble imidazoline amide

[0044] Polyethylene polyamine, glacial acetic acid and fatty acid are used as raw materials, and the ratio of raw materials is as follows:

[0045] Polyethylene polyamine 40%, glacial acetic acid 40%, fatty acid 20%.

[0046] Among them, the polyethylene polyamine is pentaethylene hexamine, and the fatty acid is nonanoic acid.

[0047] Toluene is used as a solvent, polyvinyl polyamine, glacial acetic acid and fatty acid are sequentially added to the solvent, the three raw materials are dissolved in toluene, and the amidation reaction is carried out at a temperature of 125°C for 3 hours, and the obtained product is under normal pressure, Under the condition of 220°C, the ring-closing reaction was carried out for 3 hours, and at the same time, the toluene was distilled off to obtain a water-soluble i...

Embodiment 2

[0071] The process steps for the preparation of the water-soluble imidazoline amide corrosion inhibitor are as follows.

[0072] (1) Synthesis of water-soluble imidazoline amide

[0073] Polyethylene polyamine, glacial acetic acid and fatty acid are used as raw materials, and the ratio of raw materials is as follows:

[0074] Polyethylene polyamine 50%, glacial acetic acid 20%, fatty acid 30%.

[0075] Among them, the polyethylene polyamine is diethylene triamine, and the fatty acid is oleic acid.

[0076] Using toluene as a solvent, add polyvinyl polyamine, glacial acetic acid and fatty acid to the solvent in turn, dissolve the three raw materials in toluene, and carry out amidation reaction at a temperature of 140°C for 2 hours, and the obtained product is under normal pressure, Under the condition of 240°C, the ring-closing reaction was carried out for 2 hours, and the toluene was distilled off at the same time to obtain the water-soluble imidazoline amide.

[0077] (2) ...

Embodiment 3

[0088] The process steps for the preparation of the water-soluble imidazoline amide corrosion inhibitor are as follows.

[0089] (1) Synthesis of water-soluble imidazoline amide

[0090] Polyethylene polyamine, glacial acetic acid and fatty acid are used as raw materials, and the ratio of raw materials is as follows:

[0091] Polyethylene polyamine 45%, glacial acetic acid 45%, fatty acid 10%.

[0092] Among them, the polyethylene polyamine is nonaethylene decaamine, and the fatty acid is naphthenic acid.

[0093] Using toluene as a solvent, add polyvinyl polyamine, glacial acetic acid and fatty acid to the solvent in sequence, dissolve the three raw materials in toluene, and carry out amidation reaction at a temperature of 110°C for 5 hours, and the obtained product is under normal pressure, Under the condition of 200°C, the ring-closing reaction was carried out for 5 hours, and at the same time, the toluene was distilled off to obtain a water-soluble imidazoline amide.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com