Online cleaning method of deposited salt of tower tray of normal-pressure tower

A technology of atmospheric towers and atmospheric towers, applied in the petroleum industry, hydrocarbon distillation, corrosion prevention during distillation, etc., can solve problems such as disrupting production planning arrangements, difficult production of downstream devices, prolonging processing time, etc., and shorten processing time , Save the cost of driving and parking, and the effect of low processing cost

Active Publication Date: 2010-11-10

SHENYANG PARAFFIN CHEM

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This treatment of salt deposits on the trays of the atmospheric tower will not only lead to loss of start-up and shutdown, prolong the processing time, but also seriously disrupt the production plan, make the production of downstream devices difficult, and bring greater economic losses

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

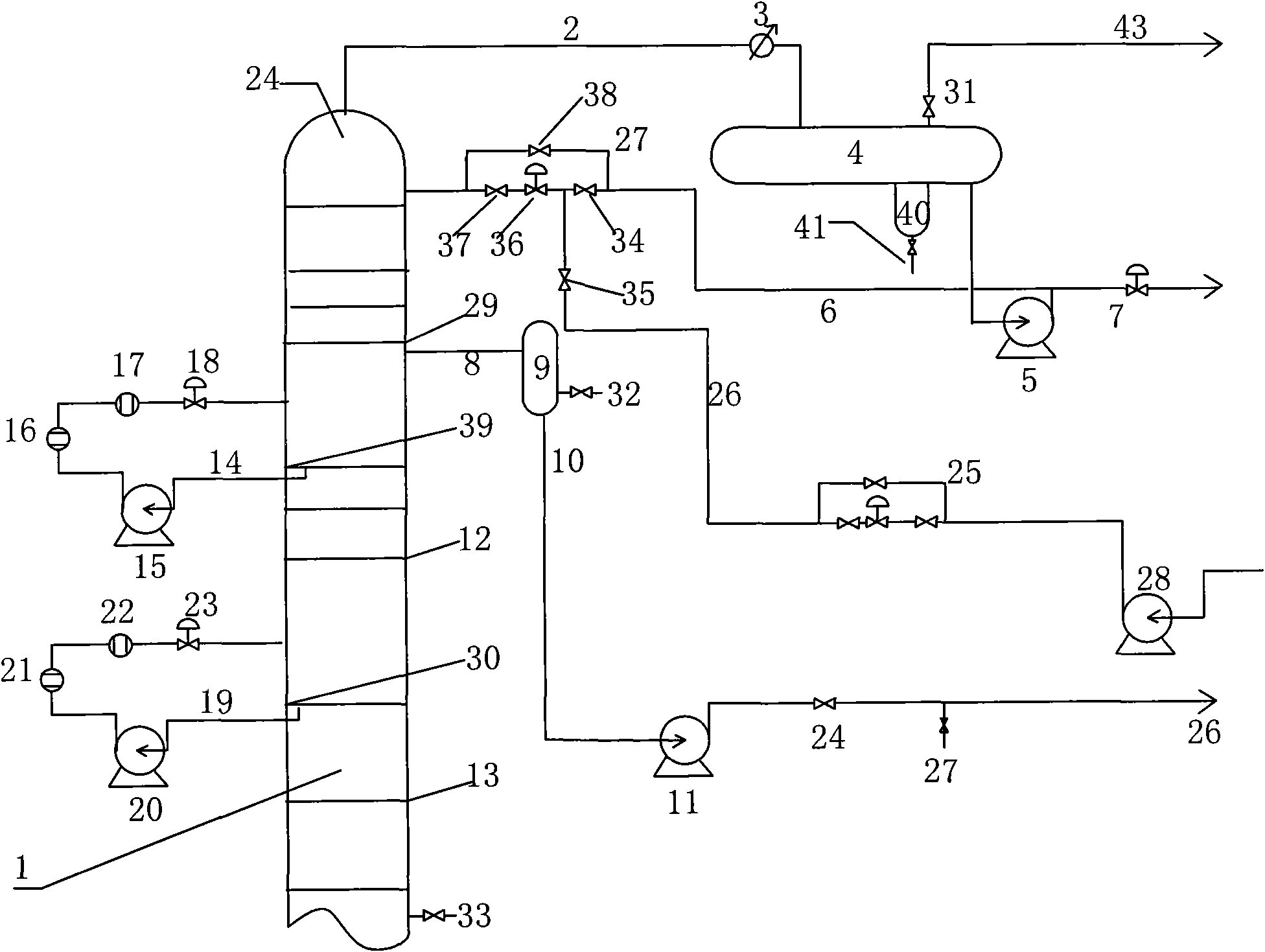

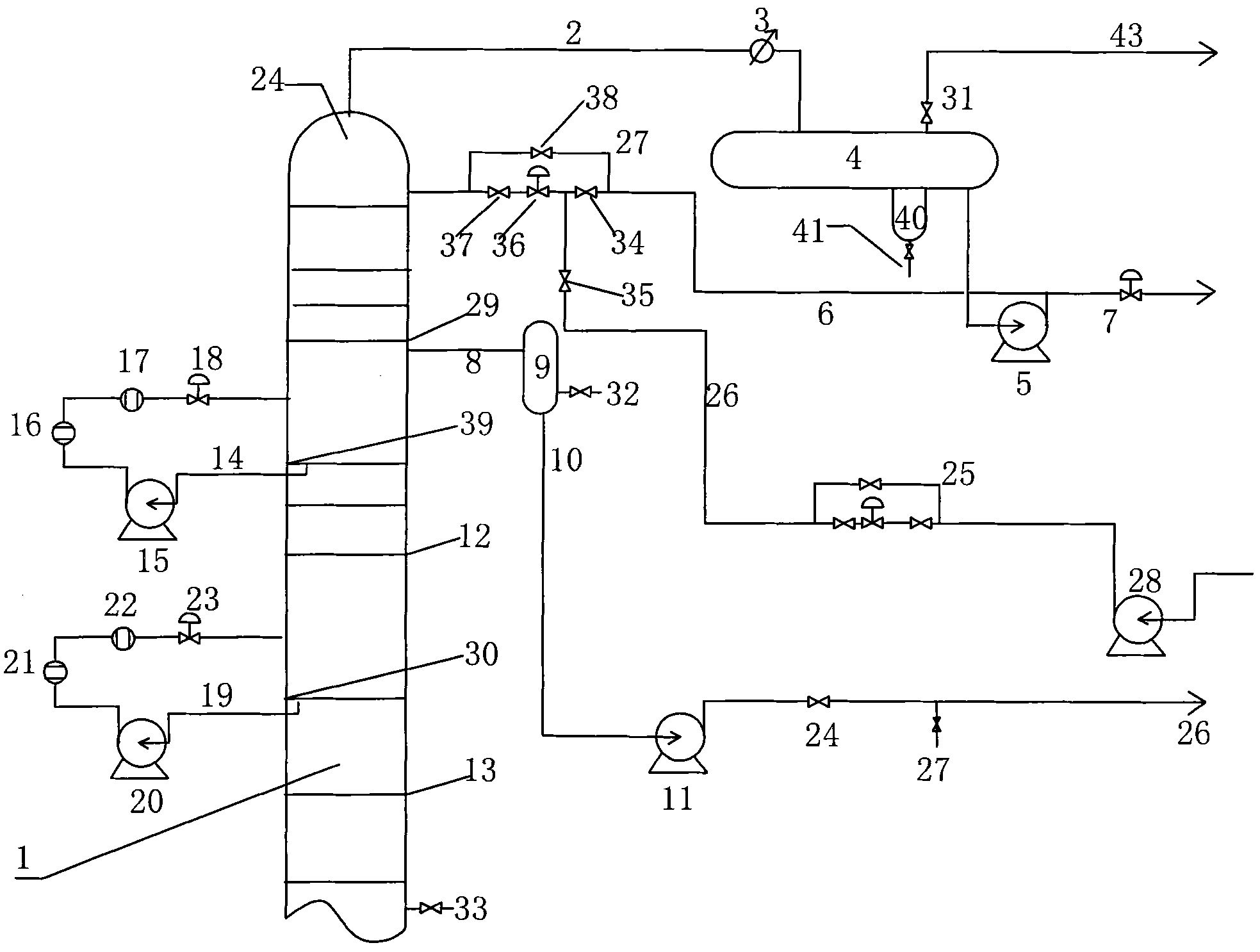

The invention relates to an online cleaning method of deposited salt of a tower tray of a normal-pressure tower. Particularly, the method comprises the following steps that: based on the original process, a cleaning pipeline is bridged between the input end of an overhead backflow regulating valve and the output end of an electro-desalting water injection regulating valve, and is provided with a bridging valve; by temporary process of communicating the bridged cleaning pipeline and an electro-desalting water injection pump and adjustment of a series of operating parameters, the temperature from the normal-pressure tower top to the tower tray of a normal-first-line pumping section is controlled to 90-100 DEG C, the normal-pressure tower top is driven into washing water, the washing water is pumped after reaching a normal-first-line distillate outlet, hot water is used for washing the tower tray of a salt depositing section continuously so as to solve the desalting problem of the deposited salt of a tower plate of the normal-pressure tower. Since the washing temperature is maintained to be constant by controlling technological parameters and the salt solubility is larger than normaltemperature, the deposited salt of the tower tray is dissolved and washed thoroughly, the device is guaranteed not to be stopped, and the whole online salt-washing treatment process needs about 8 hours; and therefore, the online cleaning method greatly shortens the treatment time, saves cost for starting and stopping the device, and furthest reduces the influence on normal production of an enterprise.

Description

A kind of on-line cleaning method of salt accumulation on the tray of atmospheric tower technical field The invention relates to the technical field of salt deposit treatment on trays in the petrochemical industry, in particular to an on-line cleaning method for salt deposits on atmospheric tower trays. Background technique Atmospheric distillation is a processing procedure of petroleum processing. Atmospheric tower is the core equipment of atmospheric equipment and is used by every petroleum processing enterprise. With the gradual scarcity of oil resources and the increasing difficulty of mining, imported crude oil and secondary exploited crude oil have gradually increased. This part of crude oil contains salt and the amount of emulsifier increases, so it is difficult to remove it in conventional electric desalting. After the salt and emulsifier enter the atmospheric tower, it will accumulate over time and cause salt accumulation on the atmospheric tray and the stripping...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G7/00C10G7/10

Inventor 郭涛颜廷武陈延涛李东王小欢

Owner SHENYANG PARAFFIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com