Carbon Disulfide Gasification Reactor Heating Device and Heating Method

A carbon disulfide, gasification reaction technology, applied in the direction of carbon disulfide, carbon sulfur compounds, etc., can solve the problems of high flue exhaust temperature, short hot gas flow, low heat energy utilization rate, etc., achieve low fuel consumption and reduce flue gas temperature. , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

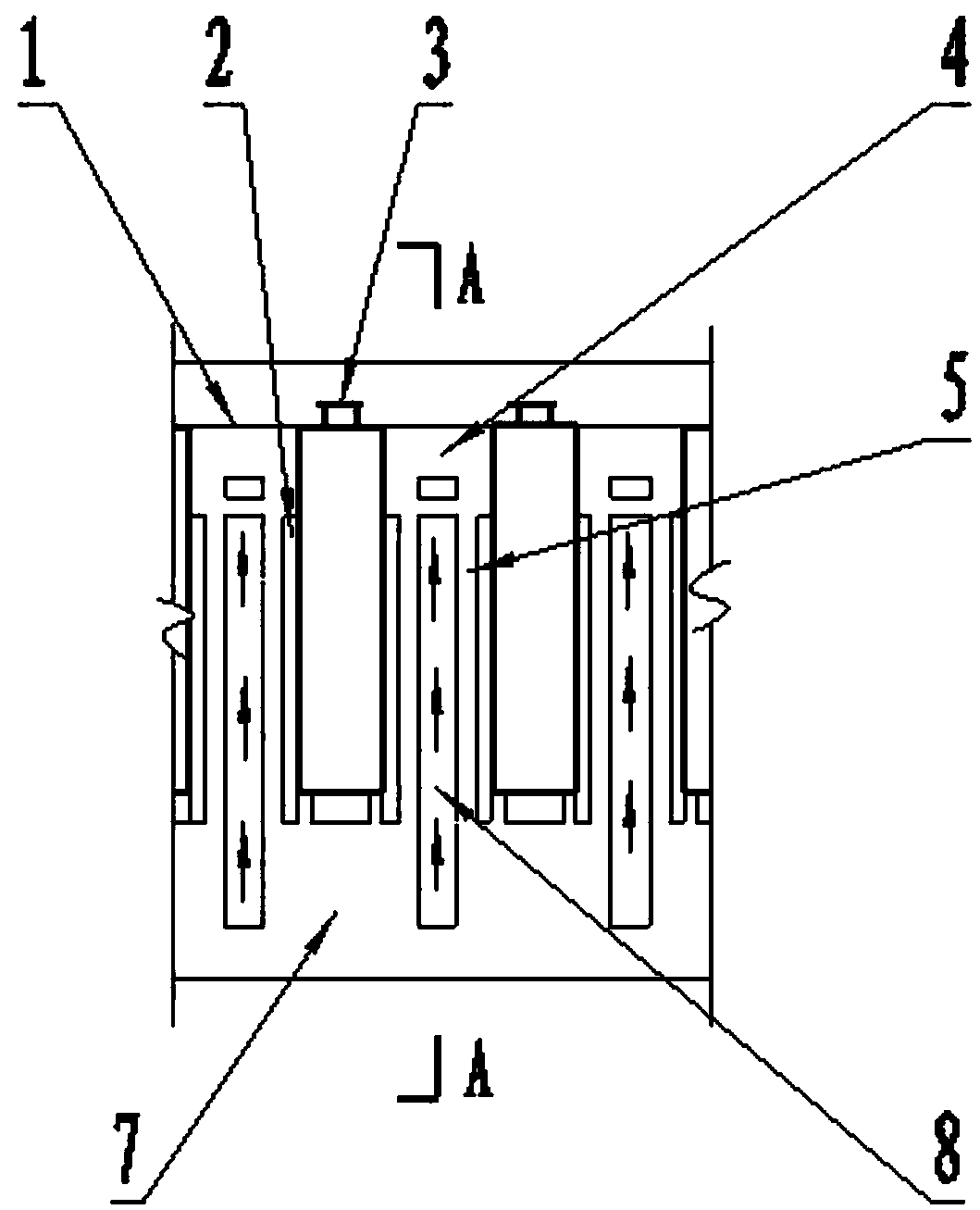

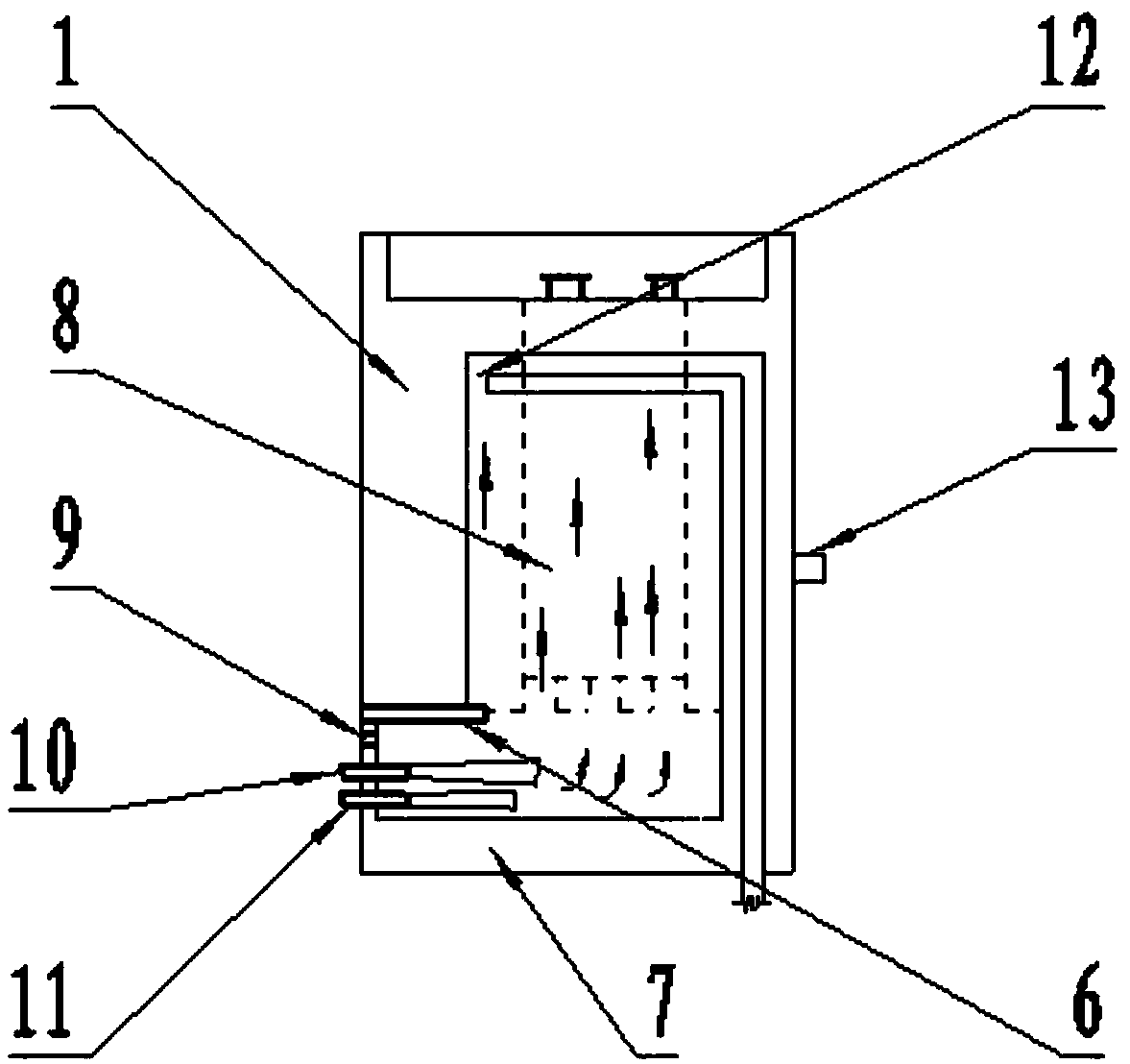

[0024] Such as Figure 3-4 As shown, a carbon disulfide gasification reaction furnace heating device in this embodiment is composed of an external heating furnace 1, a hot air flow radiation channel 2 and a carbon disulfide reaction kettle 3. The hot air radiation channel 2 is arranged between them; the external heating furnace 1 includes a furnace roof 4, a combustion chamber furnace wall 5, a support plate 6, a furnace base 7 and a combustion chamber 8; the furnace roof 4, the combustion chamber furnace wall 5 and the furnace base 7 are fixedly connected by refractory materials; the combustion chamber 8 includes an ignition hole 9, a gas fuel nozzle 10, an air inlet 11, a smoke outlet 12 and a thermometer 13; the ignition hole 9, the gas fuel nozzle 10 and the air inlet 11 are sequentially arranged on the bottom side of the external heating furnace; the support plate 6 is arranged horizontally on the top of the ignition hole 9 and extends into the combustion chamber 8; the s...

Embodiment 2

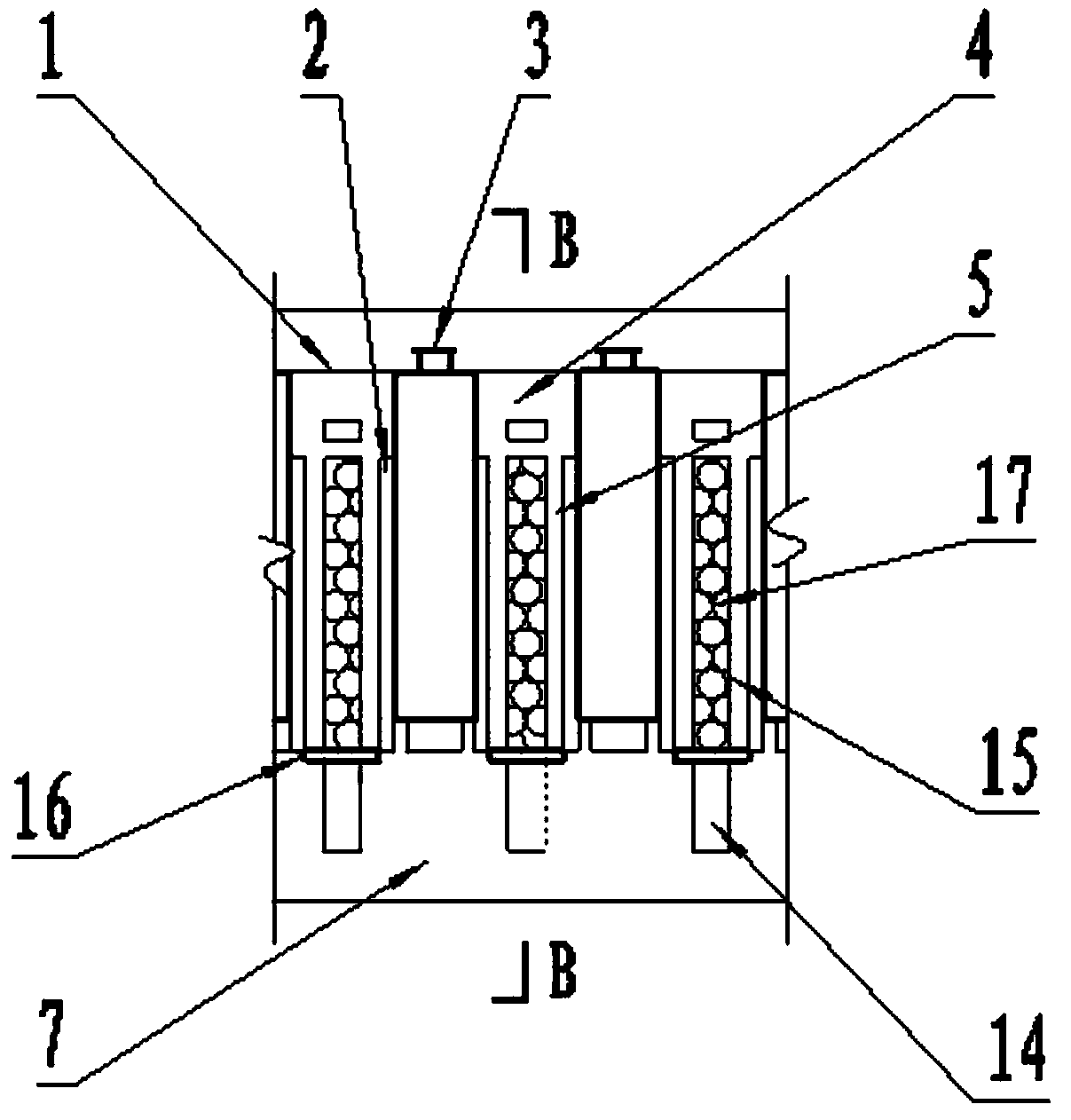

[0027] As shown in 5-6, a carbon disulfide gasification reaction furnace heating device in this embodiment, the checker brick 18 is arranged on the furnace bar 16 and the checker brick 18 is located in the upper heating regenerator 15, and the checker brick 18 vertical layered criss-cross set. The checker brick 18 is made of high alumina refractory material. All the other structures are the same as those in Example 1.

[0028] The heating method of a carbon disulfide gasification reaction furnace heating device in this embodiment is the same as the heating method in Embodiment 1 except that the refractory ball 17 is replaced by checker bricks 18 .

[0029] The coal gas in the above embodiments can also be replaced by coalbed methane or natural gas.

[0030] In the heating method in the above embodiment, after the external heating furnace 1 is turned on for heating, when the temperature in the upper heating regenerator 15 reaches 950°C-1000°C, it is also possible to reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com