A method for automatic flushing of distillation tower pipelines

A technology for automatic flushing and rectification towers, which is applied in cleaning methods and appliances, chemical instruments and methods, non-electric variable control, etc. Liquid level fluctuations and other issues to achieve the effects of reducing impact, enhancing robustness, and smooth control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to verify the effectiveness of the above scheme, combined with the actual industrial production case, the simulation verification of the above scheme is carried out in the Yokogawa CS3000 system.

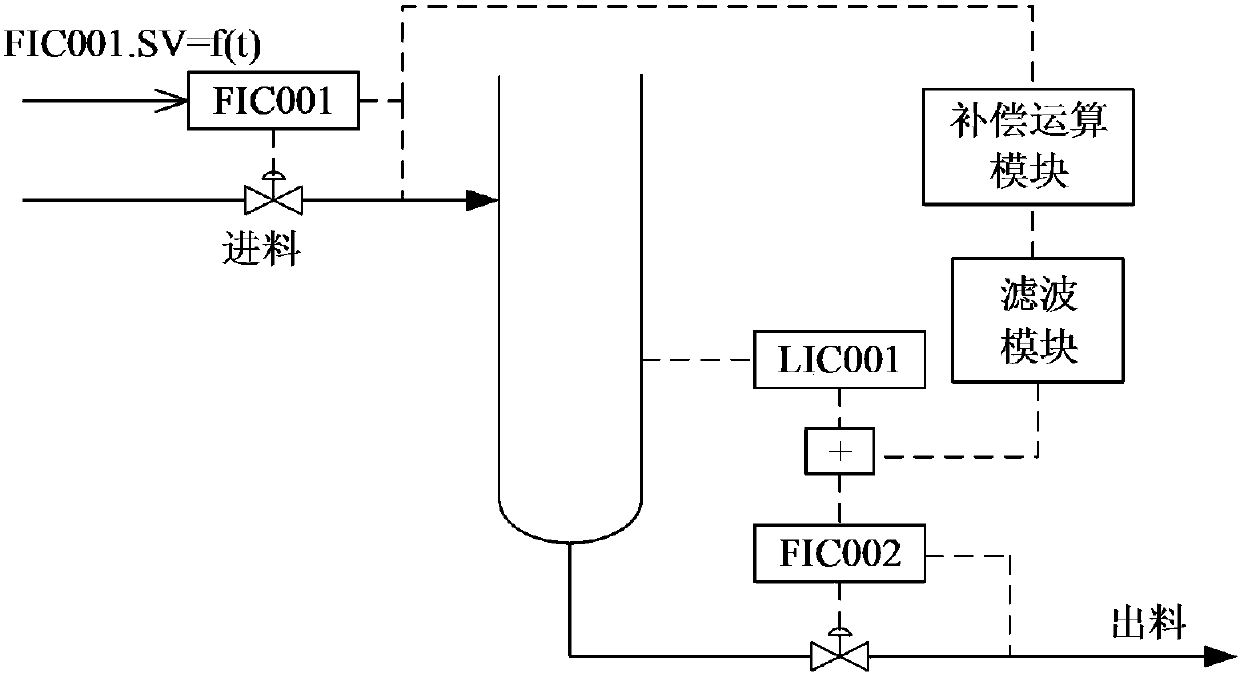

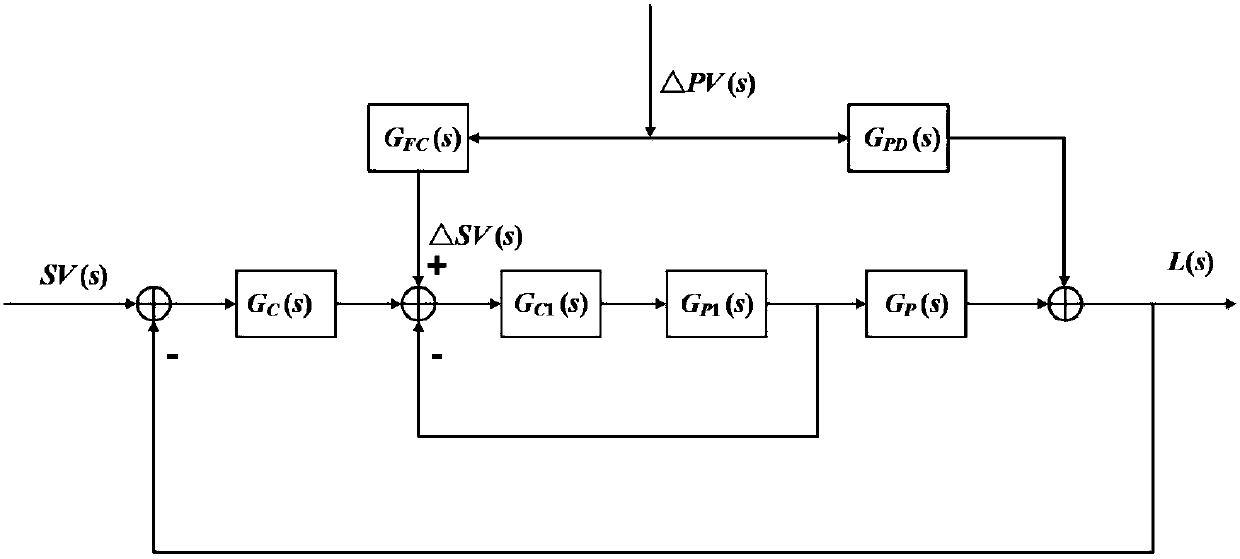

[0044] Such as figure 1 As shown, in the industrial production of ethylene, in order to prevent the discharge pipeline of the light fuel oil stripping tower in the quenching section from being blocked by the downstream heavy oil, it is usually adopted to regularly lift, maintain, and The means of reducing the amount can flush the downstream pipeline, but this will cause large fluctuations in the liquid level at the bottom of the light fuel oil tower, and the liquid level at the bottom of the tower is usually controlled by liquid level-flow cascade The control scheme is adjusted, because the liquid level object has a hysteresis problem, so the adjustment speed is often too slow when using such a control strategy. To solve this problem, the above-mentioned dynamic fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com