Repair method for partial damage of cathode carbon block at the bottom of aluminum electrolytic cell

A technology of aluminum electrolytic cell and bottom cathode, which is applied in the field of repairing the local damage of the cathode carbon block at the bottom of the aluminum electrolytic cell, which can solve the problems of increased power consumption cost, long overhaul cycle, high overhaul cost, etc., so as to prolong the service life and improve the quality of repair , The effect of reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the examples.

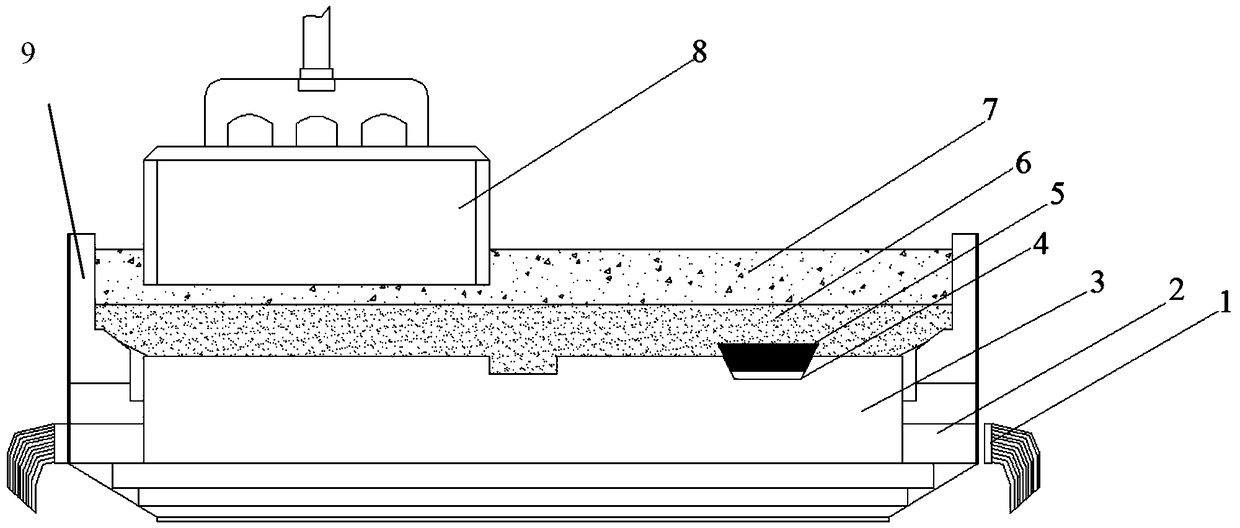

[0021] The local damage repair method of the cathode carbon block at the bottom of the aluminum electrolytic cell, such as figure 1 As shown, the steps are as follows:

[0022] (1) Use the multifunctional crane to lift the anode carbon block 8 at the damaged position of the aluminum electrolytic cell 9, use a small hook to extend into the surface of the cathode 3 of the aluminum electrolytic cell, and find out the position, shape, perimeter size, and damage depth of the damaged point 4 , determine the damage point;

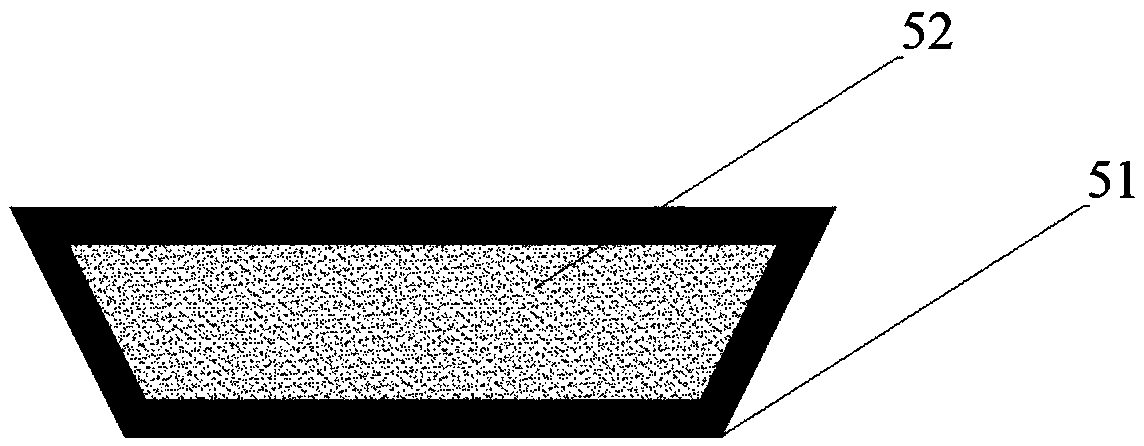

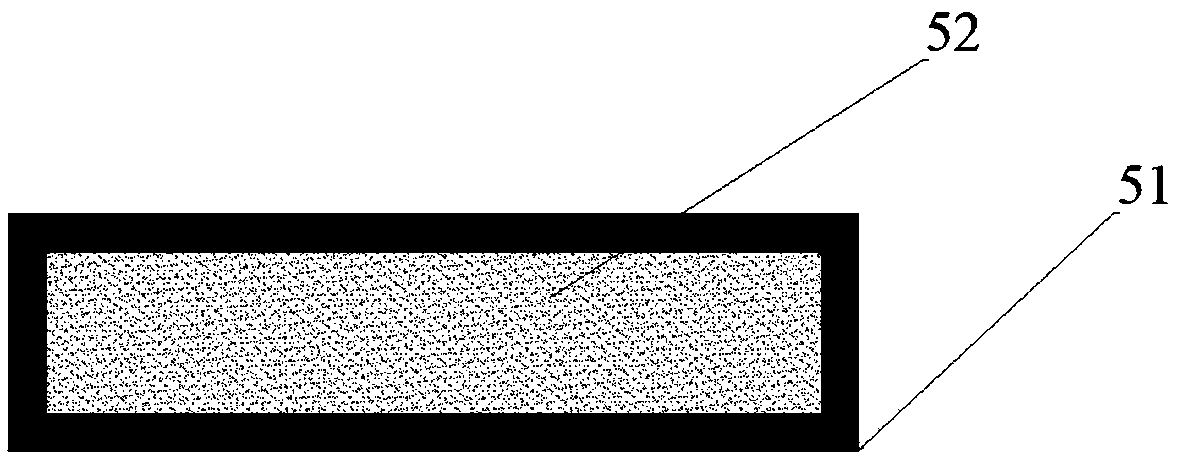

[0023] (2) According to the shape of the damaged point, select the casting mold closest to the shape of the damaged point to cast the solid aluminum module 5 coated with the repair material, and fill the solid aluminum module into the damaged point 4 . The casting method of the solid aluminum module coated with repairing material is to use two sets of molds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com