Intrinsic room-temperature self-repairing crystalline polymer

A crystalline polymer, self-healing technology, applied in organic chemistry and other directions, to achieve the effects of high repair efficiency, short repair time and high repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

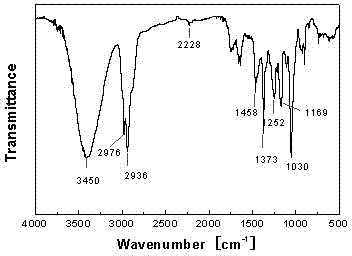

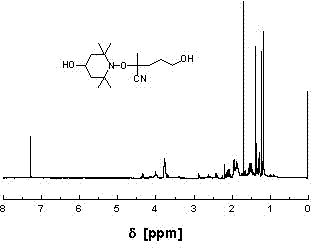

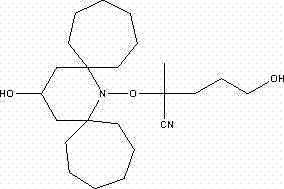

[0033] Under the protection of high-purity argon, add 200mL of benzene solution containing 2.5 parts of 4,4'-azobis(4-cyanopentanol) and 1.2 parts of 4-OH-TEMPO into the In a three-neck flask with a magnetic stirrer, stir and reflux at 80°C for 3h. After the reaction, the system was cooled to room temperature, and the solvent benzene was distilled off under reduced pressure to obtain a light yellow viscous liquid. Purified by silica gel chromatography, the eluent was petroleum ether / ethyl acetate=5:3 (v / v), collected the corresponding eluent and evaporated the solvent under reduced pressure to obtain a light yellow viscous liquid, which was purified with ethyl acetate / n-hexane Alkanes are further precipitated and purified to obtain 5-hydroxyl-2-(4-hydroxyl-2,2,6,6-tetramethylpiperidine-1-oxygen)-2-methyl-valeronitrile (abbreviated as: 4-cyano -(4-OH-TEMPO)-pentanol), the molecular structure is shown below. The IR spectrum and H NMR spectrum of the molecule are shown in figu...

Embodiment 2

[0036] 40 parts of polyethylene glycol PEG2000 (the number average molecular weight is 2000), 5.7 parts of the compound obtained in Example 1, (4-cyano-(4-OH-TEMPO)-pentanol) were added to the In a 250ml three-necked flask, heat up to 60°C to melt PEG2000, add 9.2 parts of isophorone diisocyanate monomer and 0.05 part of dibutyltin dilaurate catalyst, react at 80°C for 30 minutes and pour into a silica gel mold, argon The atmosphere was placed in an oven at 80°C to react for 24 hours, and then cooled and crystallized to obtain a crystalline linear polyurethane containing alkoxyamine. After the material was scratched or micro-cracks occurred, the cross-section was simply touched and repaired at room temperature in nitrogen for 24 hours. -48h, the crack can be repaired.

Embodiment 3

[0038] Add 120 parts of PEG2000 (the number average molecular weight is 2000), 5.7 parts of the compound obtained in Example 1, (4-cyano-(4-OH-TEMPO)-pentanol) to a 250ml three-necked In the flask, heat up to 60°C to melt PEG2000, add 18.4 parts of isophorone diisocyanate monomer and 0.14 parts of dibutyltin dilaurate catalyst, react at 80°C for 30 minutes, pour into a silica gel mold, and place in an oven under an argon atmosphere React at 80°C for 24 hours, and then cool and crystallize to obtain a crystalline linear polyurethane containing alkoxyamine. After the material is scratched or has microcracks, simply touch the cross-section and repair it in the air at room temperature for 24-48 hours, that is Cracks can be repaired.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com