Presser foot replacement device for circuit board drilling

A circuit board and presser foot technology, which is applied in the field of presser foot replacement devices for circuit board drilling, can solve problems such as inaccurate installation position, poor drilling quality, affecting drilling quality and hole position accuracy, and reduce manual operations , Improve efficiency, improve drilling quality and hole position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] The specific implementation is described as follows:

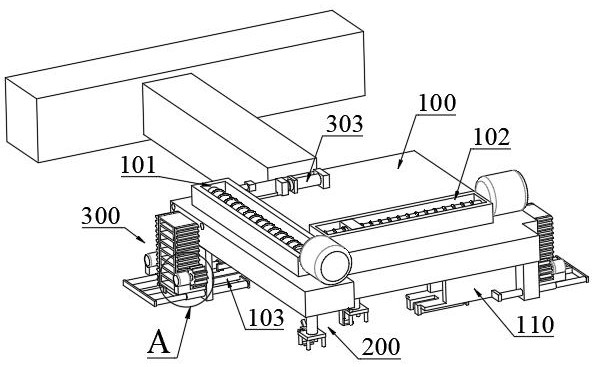

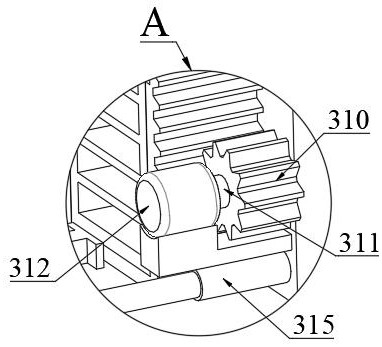

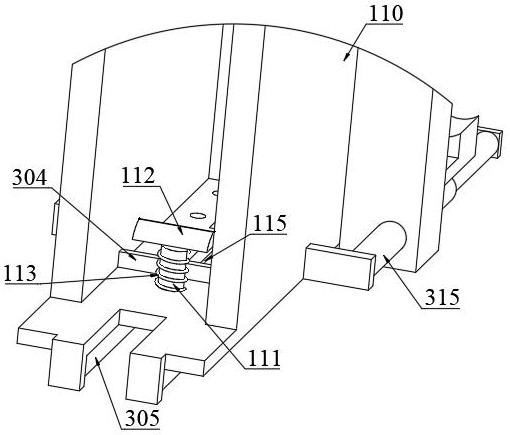

[0045] Such as figure 1 As shown, when the presser foot on the left side of the base 400 needs to be replaced, the linear mechanism is first activated to move the support base 100 to the corresponding position of the base 400, and then the turning mechanism is activated so that the support base 100 is directly above the base 400. Then start the first motor 202 located on the left side, drive the screw mandrel 201 in the first chute 101 to rotate, make the slide block 203 move towards the base 400 from the position of the lifting frame 306, start the first telescopic link 204, and make the connecting plate 205 Move downwards. During the movement, the clamping rod 206 passes through the hole on the presser foot. Since the movable plate 210 is hinged to the lower end of the support plate 207, the movable plate 210 is lifted up by the presser foot to avoid the clamping process. 210 interferes with the presser foot, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com