A spatio-temporal evaluation method for coal seam hydraulic fracturing effect

A technology of hydraulic fracturing and evaluation method, which is applied in the fields of earthwork drilling, production of fluids, wellbore/well components, etc. The effect of monitoring and evaluation, reducing construction blindness and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

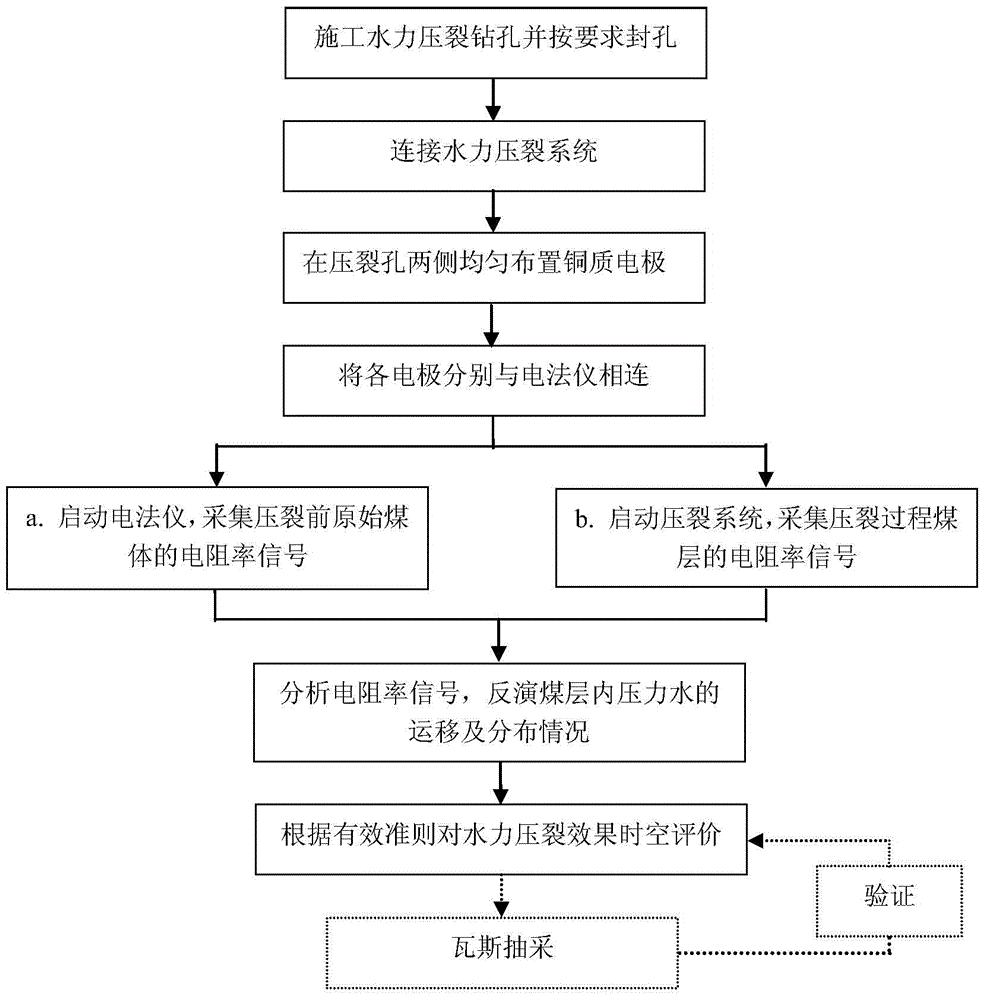

[0022] The space-time evaluation method for coal seam hydraulic fracturing effect of the present invention, concrete steps are as follows:

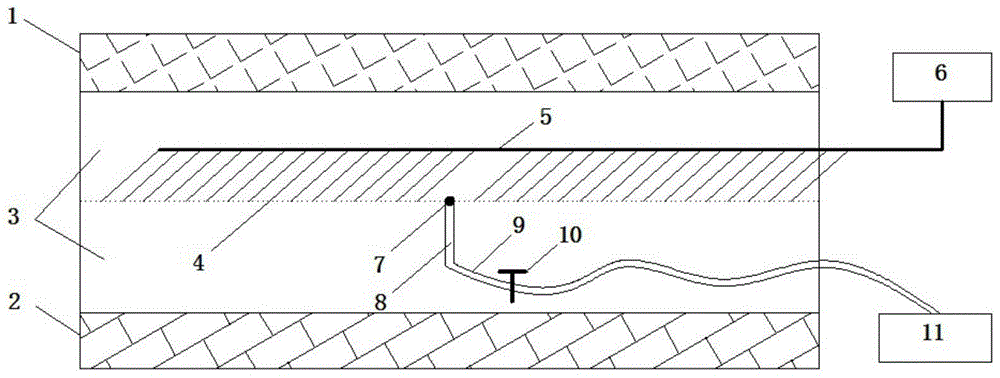

[0023] (1) Construct the fracturing hole 7 in the side of the roadway under the selected coal seam 3. The distance from the fracturing hole to the top plate 1 is 2.7-2.9 m, and the distance from the bottom plate 2 is 1.1-1.3 m. Fracturing system, the hydraulic fracturing system is composed of seamless steel pipe 8, high-pressure rubber hose 9, valve 10 and high-pressure water pump 11;

[0024] (2) With the fracturing hole 7 as the axisymmetric center, on the horizontal line where it is located, at a distance of 1.1 to 1.3 m from the bottom plate 2, a copper electrode 4 is inserted into the coal side at intervals, and is evenly arranged along the direction of the roadway 32 root electrodes, the electrode spacing is 4~6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com