Method for preventing fractionating tower from salt deposition

A fractionation tower and salt accumulation technology, which is applied in the field of preventing fractionation tower salt accumulation, can solve problems such as no fractionation tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

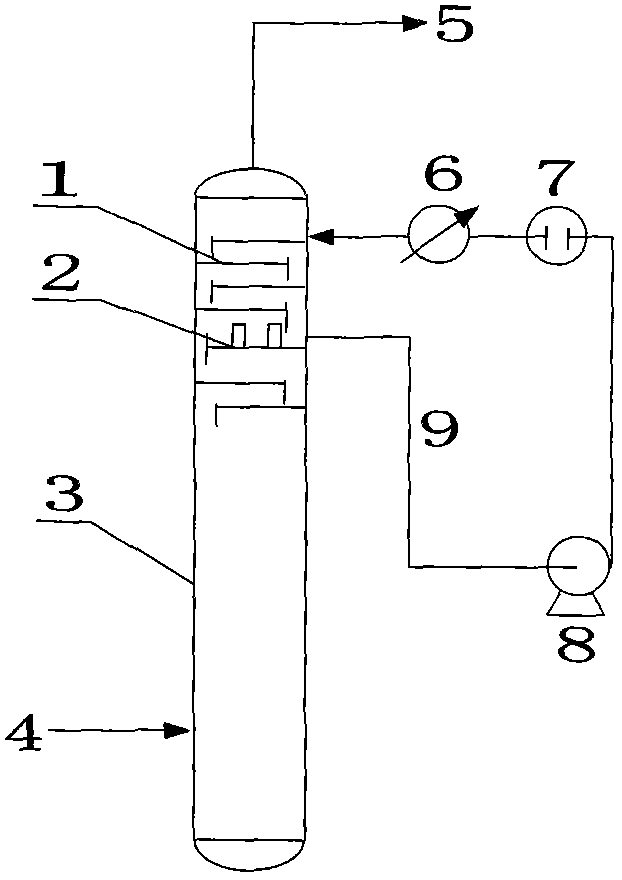

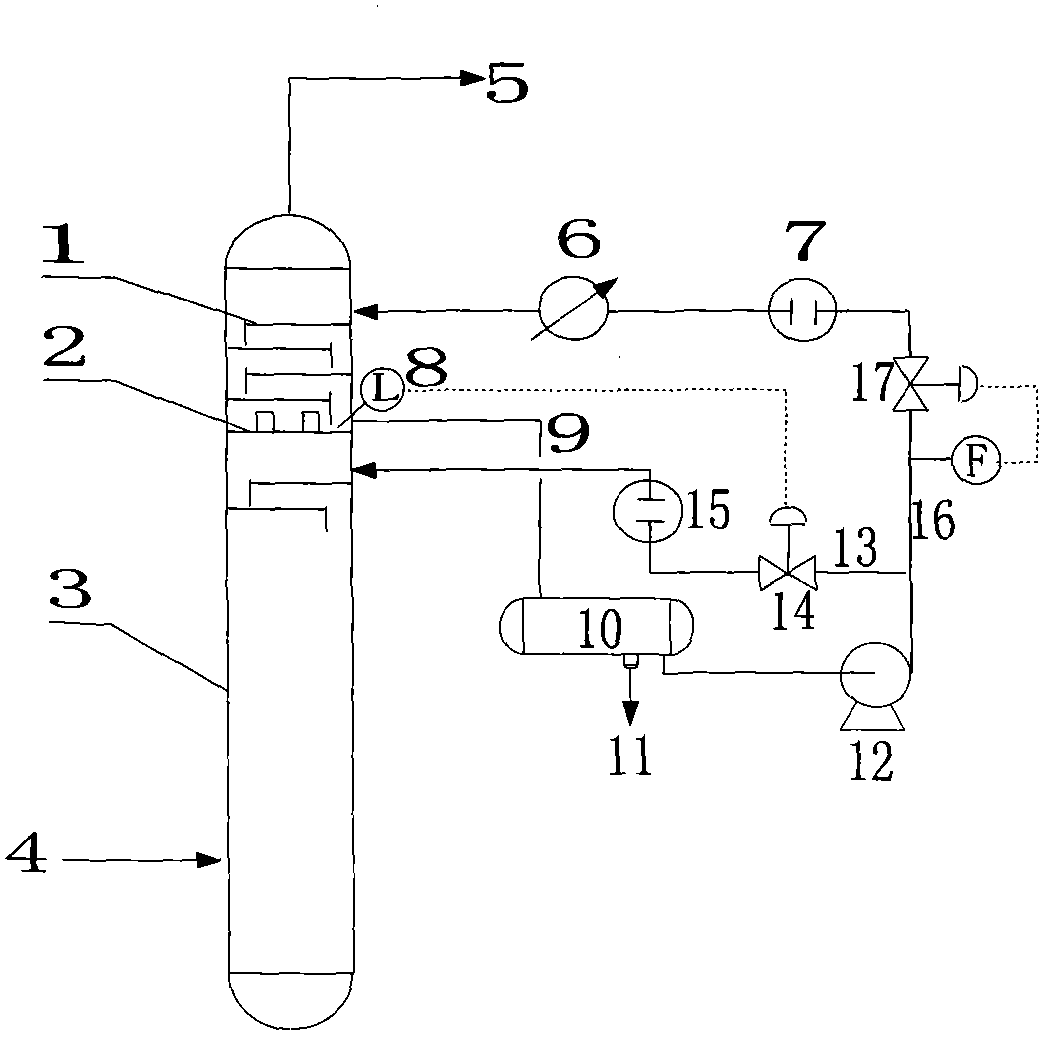

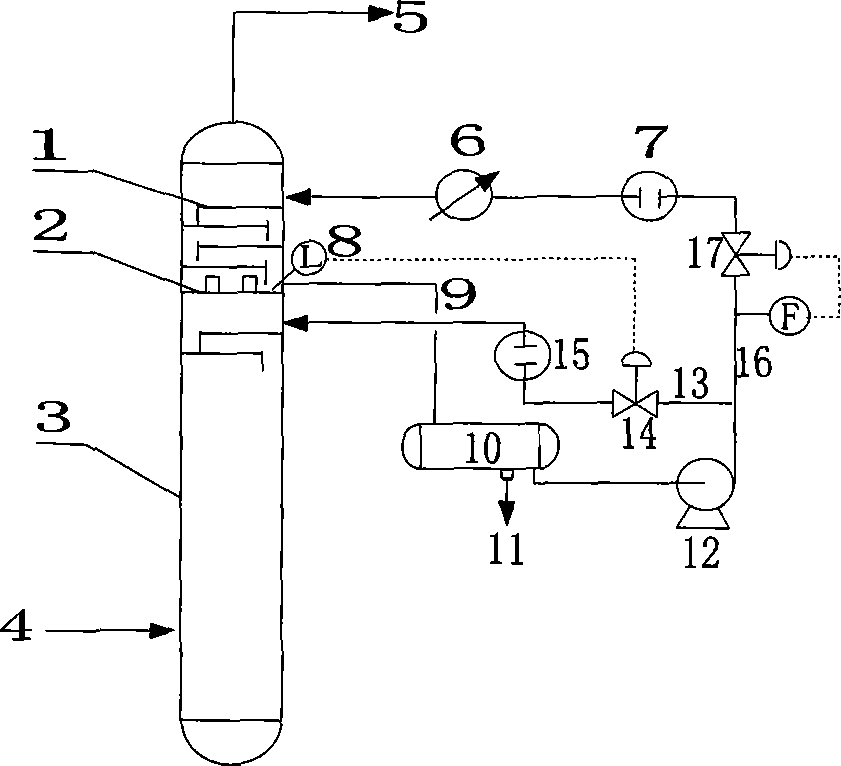

[0015] figure 2 A catalytic cracking unit anti-salt fractionation tower and schematic flow diagram are provided. The upper part of the fractionation tower 3 is provided with a top circulation reflux section, including a 3-4 layer tower plate 1 and an oil collection tank 2, and a liquid level gauge 8 is located in the oil collection tank 2. Top cycle dehydration facilities include dehydration tank 10, top cycle oil pump 12, lower return tower regulating valve 14, lower return tower heat exchanger 15, upper return tower cooler 6, upper return tower heat exchanger 7, upper return tower regulating valve 17.

[0016] The reaction oil gas 4 containing water vapor, NH3 and HCl at 480-500°C enters from the lower part of the fractionation tower 3 . The oil gas rises in the fractionation tower and enters the top circulation reflux area. The temperature of the top circulation oil returns to the tower is low (60-90°C), so that part of the water vapor in the oil gas condenses into water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com