Process for treating salt deposition in fractionating tower

A fractionation tower and salt formation technology, which is applied in the field of corrosion control of oil refinery units, can solve problems such as time-consuming, equipment shutdown or reduction, and hidden dangers of corrosion, and achieve the effects of easy on-site operation, avoiding under-deposit corrosion, safety, time saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

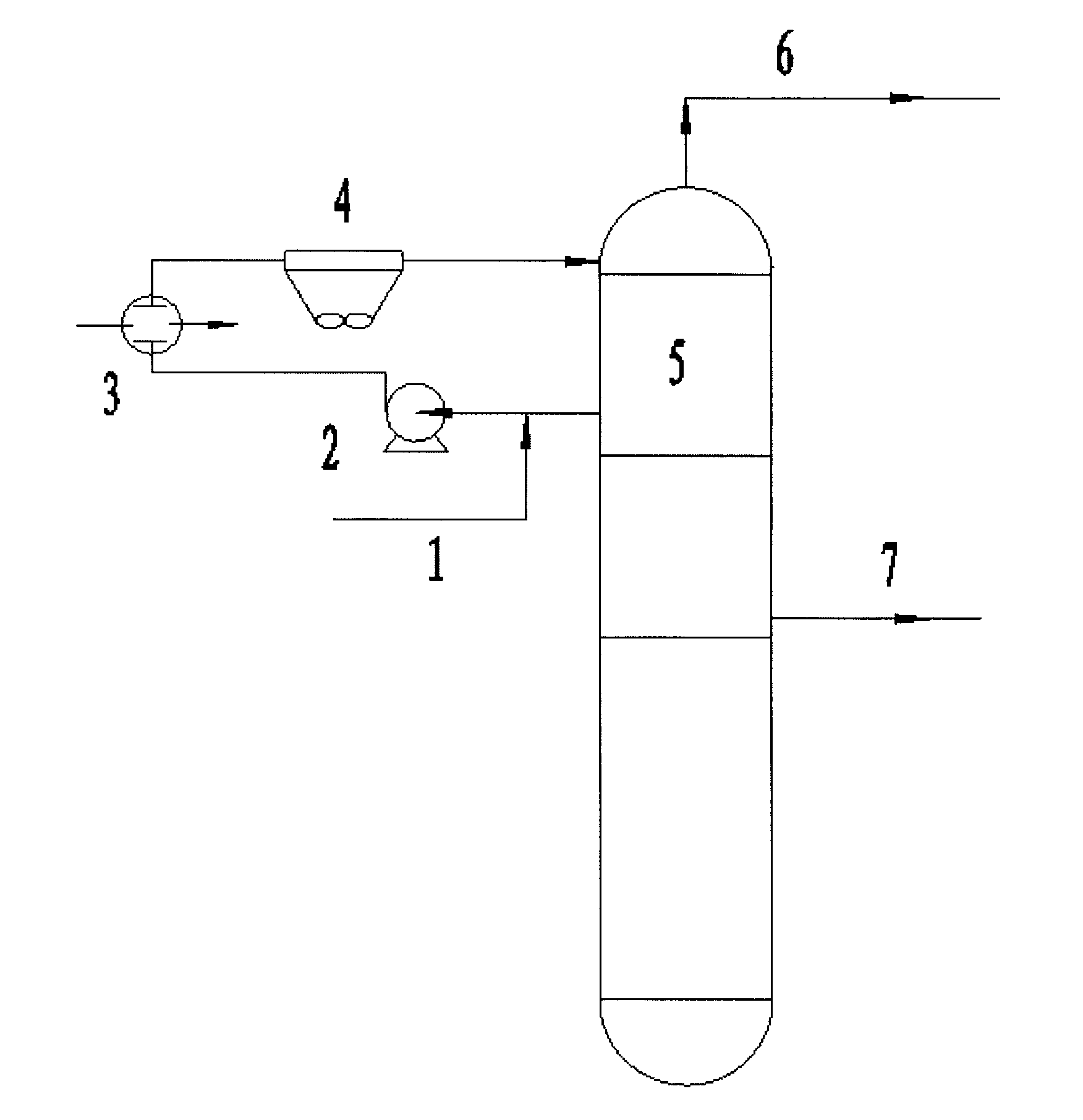

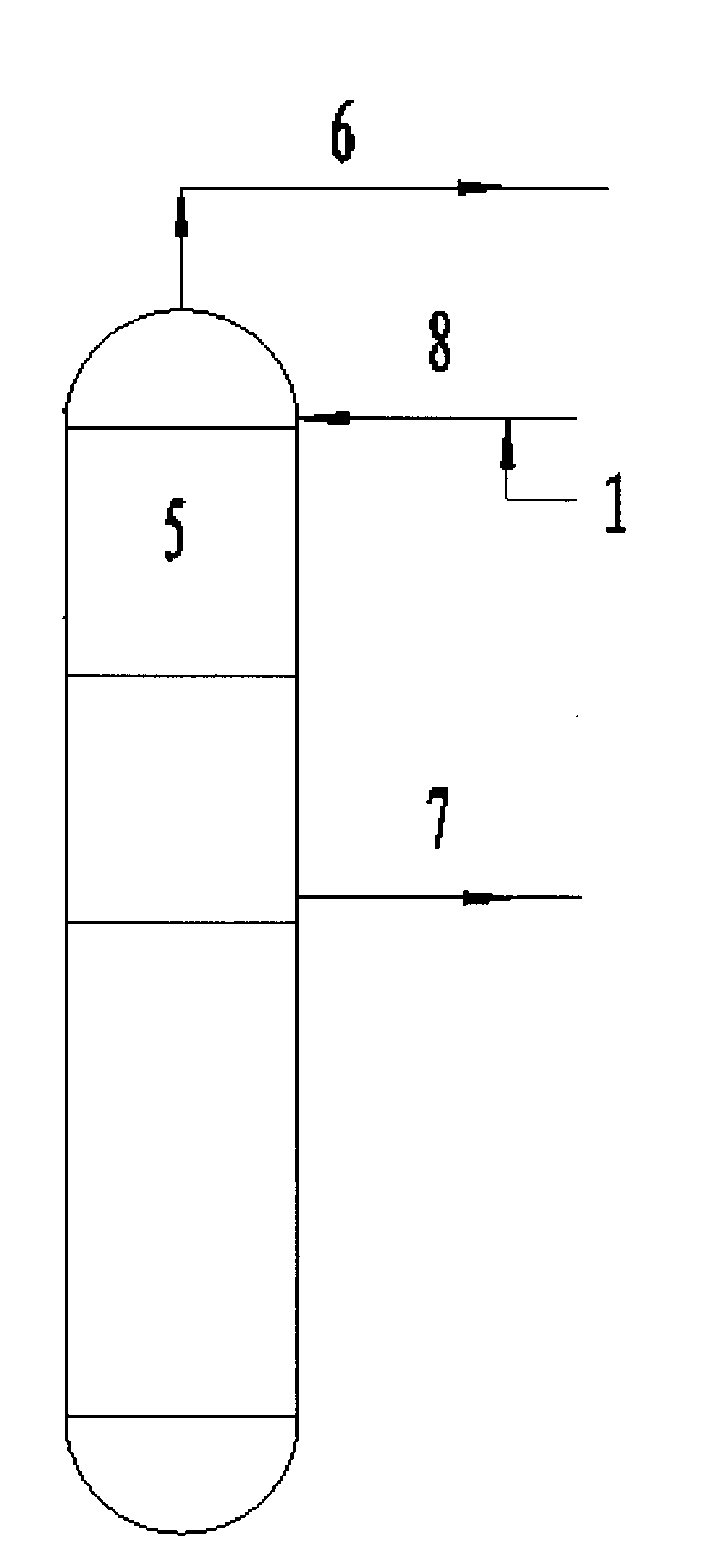

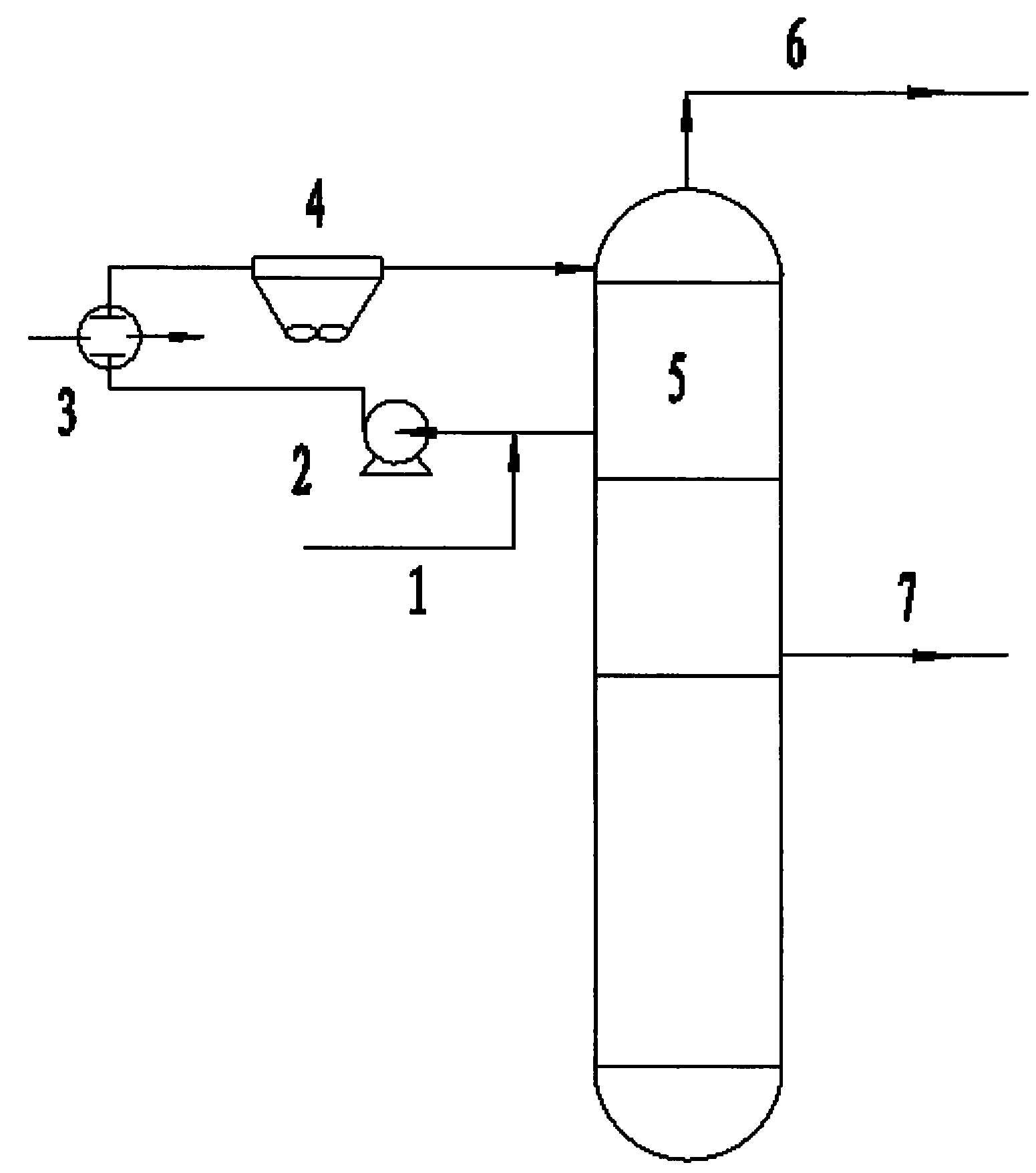

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is to test the inhibitory ability of the inhibitor to ammonium chloride crystalline salt. In a 200mL three-necked flat-bottomed flask, add 100 grams of catalytic gasoline from a refinery. The properties of the catalytic gasoline are shown in Table 1, then add 1 gram of ammonium chloride solid powder, stir slowly in a water bath at 50°C, and stop stirring after 30 minutes. A solid powder of ammonium chloride was observed to deposit on the bottom of the flask. Slowly add 1.5 grams of the inhibitor in the catalytic gasoline with a dropper in a ratio of dodecylamine: tetraethylenepentamine: n-butanol: heavy aromatics = 30: 35: 15: 20, slowly stir Find that the ammonium chloride solid powder disappears gradually, and observe that bubbles escape in gasoline, stop stirring after 5 minutes and find that the ammonium chloride solid powder disappears completely.

[0032] Table 1 Properties of catalytic gasoline

[0033] catalytic gasoline

Embodiment 2

[0035] In the delayed coking unit of a refinery, the coking fractionation column often has large fluctuations in the top cycle, and the top cycle pump often evacuates intermittently, and the temperature at the top of the tower fluctuates greatly, the dry point of naphtha rises, and the color turns black. After salt formation occurs in the coking fractionation tower, a salt formation inhibitor is added before the inlet of the top circulating pump of the fractionation tower. The ratio of the salt formation inhibitor is isooctylamine: dodecylamine: n-butanol: heavy aromatics = 30:30: 20:20, the addition amount is 40mg / kg, and after 36 hours of operation, the operation of the fractionation tower returns to normal. Table 2 shows the properties of coked gasoline before and after adding the salt formation inhibitor.

[0036] Table 2 Properties of coker gasoline before and after adding salt inhibitor

[0037] catalytic gasoline

Embodiment 3

[0039] The heavy oil catalytic cracking unit of a refinery often has the problem of salt accumulation in the fractionation tower, the pressure drop of the tray increases, and the dry point of gasoline products fluctuates greatly. , after salt formation occurs in the catalytic cracking fractionation tower, a salt formation inhibitor is added to the top reflux line, and the salt formation inhibitor ratio is dodecylamine: tetraethylenepentamine: n-butanol: heavy aromatics=30:35: 15:20, the injection amount is 30mg / kg, after 45 hours of operation, the operation of the fractionation tower returns to normal. Table 3 shows the properties of the catalytic gasoline before and after adding the salt formation inhibitor.

[0040] Table 3 Properties of Catalyzed Gasoline Before and After Adding Salt Deposition Inhibitor

[0041] catalytic gasoline

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com