Screw type negative pressure pulsed hydroscillator

A hydraulic oscillator and screw-type technology, which is applied to vibration drilling, vibration generating devices, boreholes/well components, etc., can solve the problem of unsatisfactory use of axial vibration tools, inability to effectively transmit wellhead drilling pressure, and drilling fluid carryover. The rock capacity is not high enough to achieve the effect of increasing the life, improving the rock-carrying ability, and increasing the drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

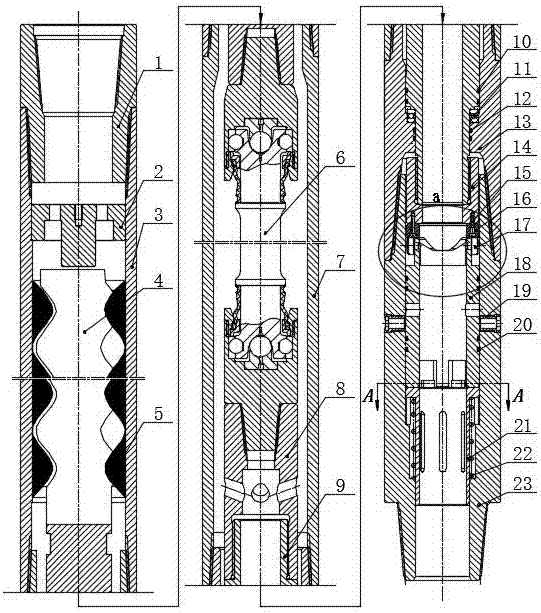

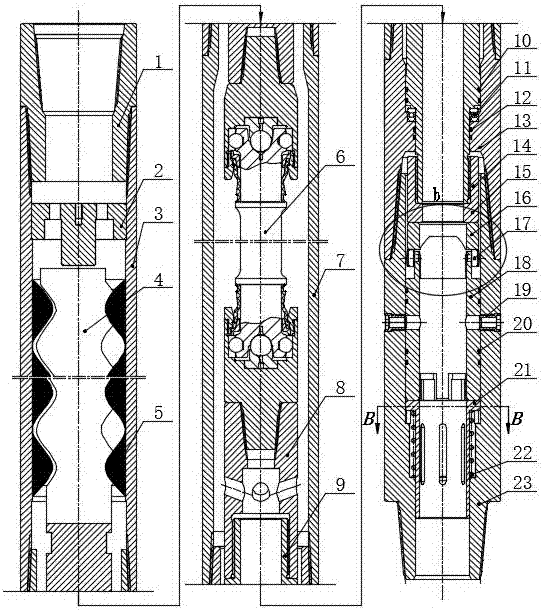

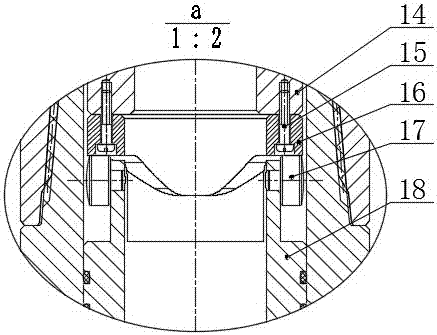

[0017] The present invention will be further described below in conjunction with the accompanying drawings: According to the accompanying drawings, the screw-type negative pressure pulse hydraulic oscillator is mainly composed of three parts: a power assembly, a transmission assembly and a valve assembly, and the power assembly consists of an upper joint 1. Rotor compression cap 2, stator shell 3 screw rotor 4, rubber stator 5; transmission assembly consists of cardan shaft 6, transmission shaft 8 and overcurrent transmission shaft; valve assembly consists of cam seat 14, cam 16, Roller 17, spool 18, nozzle 19, spring seat 21, spring 22, lower joint 23, etc.; upper joint 1, stator housing 3, cardan shaft housing 7, bearing support nipple 13, lower joint 23 pass through the thread in turn Connection; the rotor compression cap 2 is located inside the stator housing 7, between the upper joint 1 and the screw rotor 4, and the rotor compression cap 2 and the stator housing 3 adopt a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com