Well cleaning functional type drill pipe

A functional and clean technology, used in drill pipe, flushing wellbore, wellbore/well components, etc., which can solve the problem of large wear resistance of supporting pressure drill string, increased drill string supporting pressure, increased wear resistance, and mud carrying capacity. It can reduce problems such as reducing short trips, reduce operating time, and improve rock-carrying capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

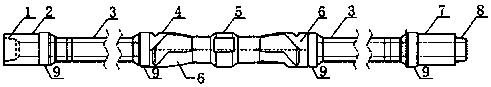

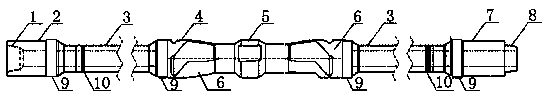

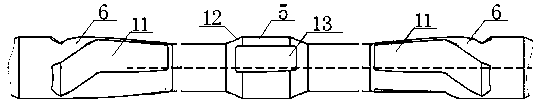

[0020] A drill pipe with wellbore cleaning function, comprising a pipe body 3, an internally threaded joint 2 and an externally threaded joint 7, the pipe body 3 is welded to the internally threaded joint 2 and the externally threaded joint 7 respectively, and the pipe body 3 is connected to the internally threaded joint 2 There is a weld 10 at the welding place with the external threaded joint 7; a thickening section 4 is arranged in the middle of the pipe body 3, and the two ends where the thickening section 4 intersects with the pipe body 3 are respectively processed with a tapered section 6, and the middle of the thickening section 4 is The cylindrical section 5 ; the internal threaded joint 2 and the external threaded joint 7 are respectively processed with an internal thread 1 and an external thread 8 that can cooperate with each other.

[0021] The outer diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com