Filling method for reducing onway resistance losses of paste-like slurry

A paste filling and resistance loss technology is applied in the filling field of paste filling and reducing the resistance loss along the path of paste slurry, which can solve the problem of pipeline burst, increase of working pressure of paste filling pump and large resistance loss along the path. and other problems to achieve the effect of improving compressive strength, reducing paste pump pressure and increasing slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

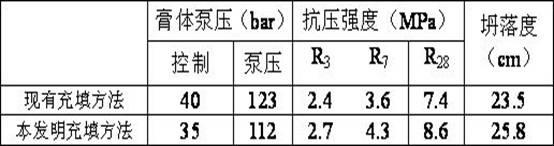

Embodiment 1

[0022] Adopt the existing paste filling system, set an iron container with a size of 3000mm * 3000mm * 1500mm above the stirring tank of the paste filling system, and connect the container with an electric flow pump; adopt the existing method to prepare a weight concentration of 80 % paste slurry, the weight ratio of rod grinding and tailing sand in the paste slurry is 1:1, and the paste slurry contains 300kg cement and 100kg fly ash per cubic meter. When adding cement, control the amount of cement The flow rate is 35t / h; the prepared paste slurry is sent into an iron container; the electric flow pump is turned on, and the JKJ-NF type high-efficiency pumping water reducer is added to the container to form a mixed paste filling slurry; The weight of the water-reducing agent is 1.5% of the total weight of the mixed paste filling paste slurry; send the formed mixed paste slurry into the stirring tank of the filling system, stir evenly, and control the temperature in the stirring t...

Embodiment 2

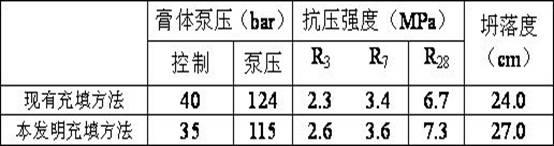

[0028] Using the existing paste filling system, set an iron container with a size of 3000mm×3000mm×1500mm above the mixing tank of the paste filling system, and connect the container with an electric flow pump; use the existing method to prepare a weight concentration of 78% The paste slurry, the weight ratio of rod grinding and tailing sand in the paste slurry is 1.5:1, the paste slurry contains 300kg cement and 150kg fly ash per cubic meter, control the flow of cement when adding cement It is 35t / h; send the prepared paste slurry into the container; turn on the electric flow pump, and add JKJ-NF high-efficiency pumping water reducer into the container to form a mixed paste filling slurry; the addition and subtraction The weight of the water agent is 1% of the total weight of the mixed paste filling paste slurry; the formed mixed paste slurry is sent to the stirring tank of the filling system, stirred evenly, and the temperature in the stirring tank is controlled to be 30 °C a...

Embodiment 3

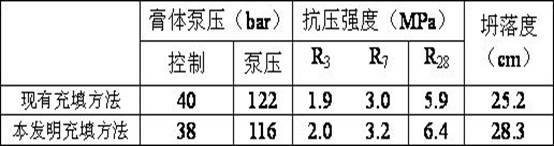

[0034]Using the existing paste filling system, an iron container with a size of 3000mm×3000mm×1500mm is set above the stirring tank of the paste filling system, and the container is connected with an electric flow pump; the weight concentration of 79% is prepared by using the existing method The paste slurry has a weight ratio of rod scrub and tailings of 1.25:1. Each cubic meter of the paste slurry contains 300kg of cement and 125kg of fly ash. When adding cement, control the flow of cement. is 35t / h; the prepared paste slurry is sent into the container; the electric flow pump is turned on, and the JKJ-NF type high-efficiency pumping water reducing agent is added into the container to form a mixed paste filling slurry; the added and subtracted The weight of the water agent is 1.25% of the total weight of the mixed paste filling paste slurry; the mixed paste slurry is sent into the stirring tank of the filling system, stirred evenly, and the temperature in the stirring tank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com