A kind of super high-rise jacking self-compacting concrete and its construction technology

A self-compacting concrete and super-high-rise technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of rough surface of machine-made sand, poor concrete fluidity, high viscosity of concrete, etc., and achieve improved impermeability and water resistance. Carbonization ability, improved crack resistance, and reduced drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

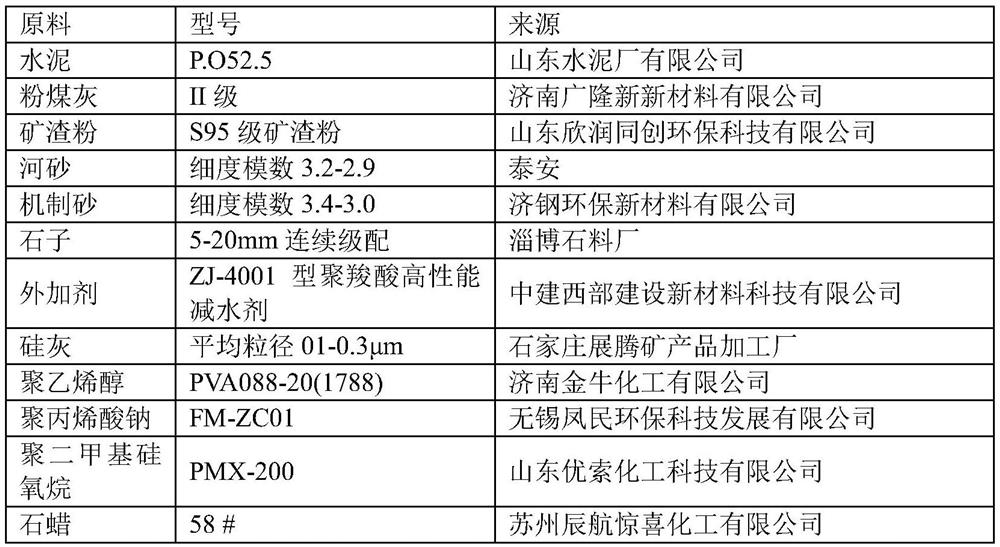

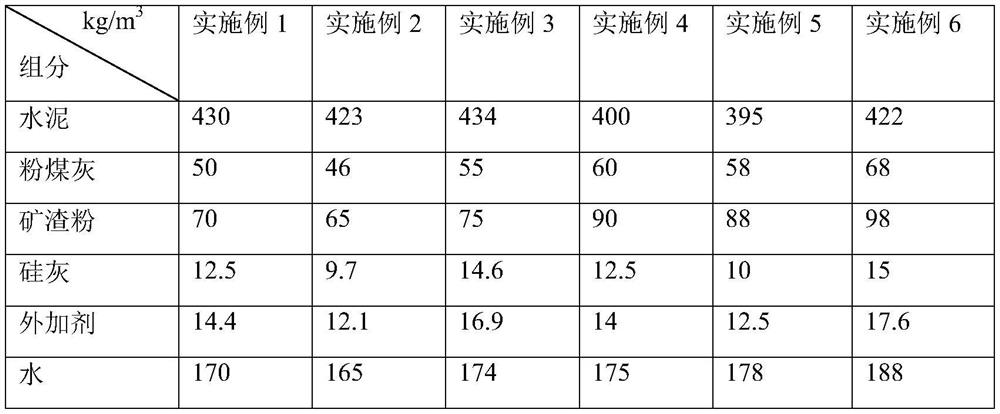

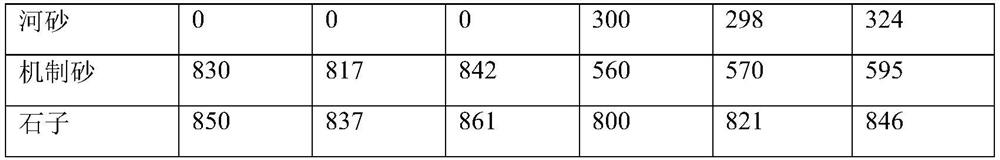

Method used

Image

Examples

preparation example 1-4

[0043] In Preparation Example 1-4, carrageenan was selected from Jinan Aoxiang Chemical Co., Ltd., with item number AOX68; chlorinated paraffin was selected from Dongying Huaxuan Biotechnology Co., Ltd., with item number HX-2348; It is A001; linseed oil is selected from Shanghai Fengrui Chemical Co., Ltd., product number is FR-76546; aramid fiber is selected from Foshan Yuesheng New Material Technology Co., Ltd., product number is G596, and the length is 120mm; silane coupling agent is selected from Henan Chuangxiang Chemical Products Co., Ltd., the product number is KH-550; EVA is selected from Suzhou Guanghuichun Engineering Plastic Materials Co., Ltd., the product number is 40W, and the melting point is 47 °C; styrene is selected from Dongwanshi Xindu Chemical Co., Ltd., the model is XD-b01.

preparation example 1

[0044] Preparation Example 1: Mix, dry and pulverize 2kg carrageenan, 0.8kg glycerin, 1kg modified aramid fiber, and 0.05kg linseed oil. Modified aramid fiber is made from aramid fiber after drying at 80°C for 10 hours It is immersed in an aqueous solution of a silane coupling agent with a concentration of 1.5% by mass, reacted at 50° C. for 5 hours, and then dried.

preparation example 2

[0045] Preparation Example 2: The difference from Preparation Example 1 is that no modified aramid fiber is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com