Viscosity-reducing agent for vibration-free concrete and preparation and use methods thereof

A concrete and viscosity reducer technology, applied in the field of concrete admixtures, can solve the problems of poor viscosity reduction effect and concrete strength reduction, and achieve the effects of ensuring strength, improving fluidity and reducing pumping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

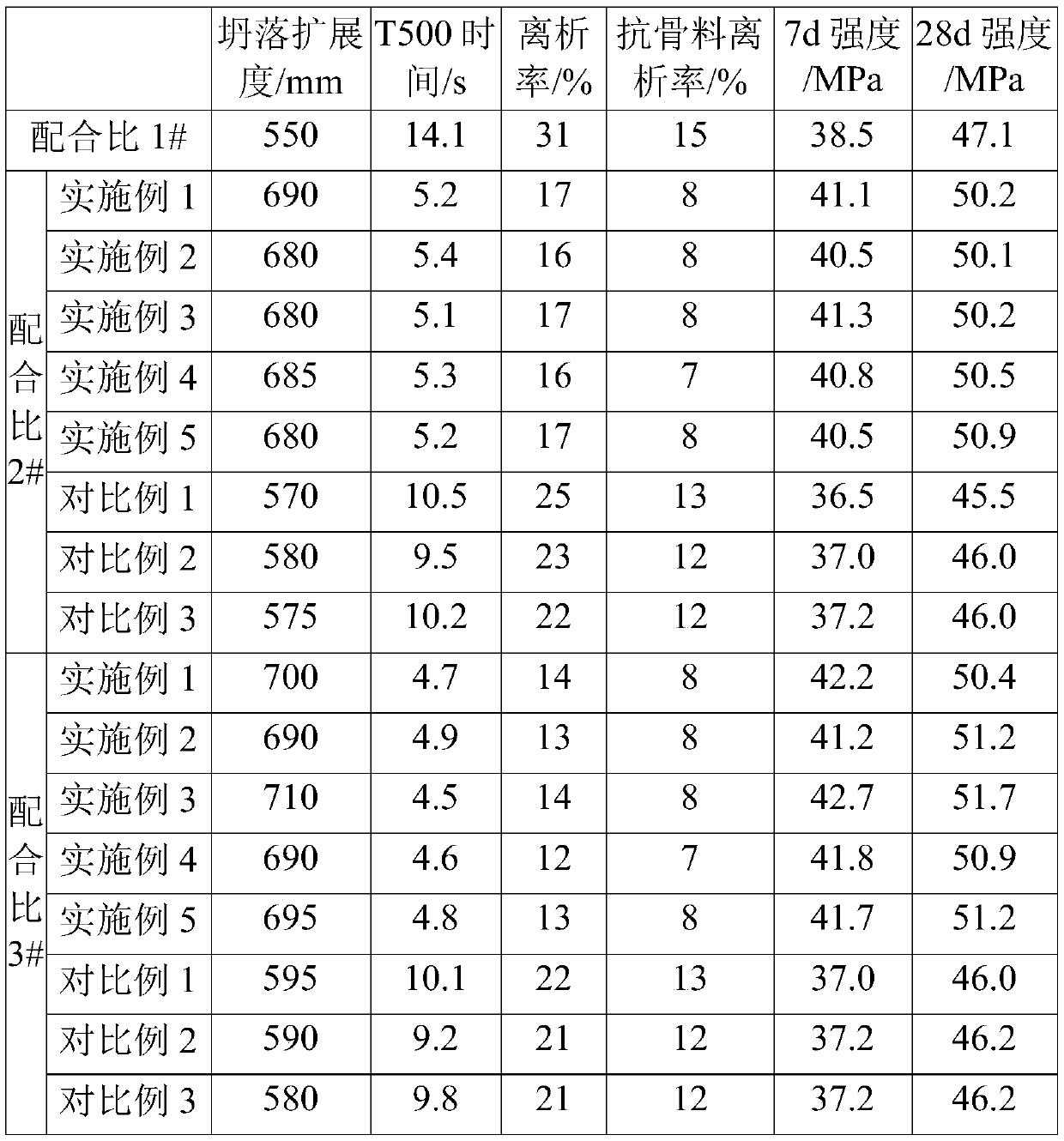

Examples

Embodiment 1

[0031] This embodiment provides a viscosifier for non-vibration concrete, which includes the following components in terms of weight percentage: 15% of microsilica fume, 25% of ultrafine slag powder, 20% of glass powder, and microbead fly ash particles 35%, alcohol amine compound 0.2%, defoamer 0.1%, air-entraining agent 0.1% and inorganic activator 4.6%.

[0032] The specific surface area of the above micro silica fume is 15000m 2 / Kg, loose bulk density is 330kg / m 3 , wherein the mass content of silicon dioxide is 92%; the specific surface area of the above ultrafine slag powder is 1500m 2 / Kg; the fineness of the above-mentioned glass powder is 300 orders; the water demand ratio of the above-mentioned microbead fly ash particles is 85%, and the 7-day activity index is 85%; the above-mentioned defoamer is tributyl phosphate; the above-mentioned air-entraining agent It is triterpene saponin; the above-mentioned inorganic stimulant is gypsum; the above-mentioned alcohol ...

Embodiment 2

[0038] This embodiment provides a viscosifier for vibration-free concrete, which comprises the following components in terms of weight percentage: 10% microsilica fume, 30% ultrafine slag powder, 14.65% glass powder, microbead fly ash particles 35%, alcohol amine compound 0.1%, defoamer 0.1%, air-entraining agent 0.15% and inorganic activator 10%.

[0039] The specific surface area of the above micro silica fume is 20000m 2 / Kg, loose bulk density is 350kg / m 3 , wherein the mass content of silicon dioxide is 90%; the specific surface area of the above ultrafine slag powder is 10000m 2 / Kg; the fineness of the above-mentioned glass powder is 400 orders; the water demand ratio of the above-mentioned microbead fly ash particles is 87%, and the 7-day activity index is 100%; the above-mentioned defoamer is organosilicon oil; the above-mentioned air-entraining agent is three Terpene saponin; the above-mentioned inorganic stimulant is sodium carbonate; the above-mentioned alcoh...

Embodiment 3

[0045]This embodiment provides a viscosifier for non-vibration concrete, which includes the following components in terms of weight percentage: 30% of microsilica fume, 5% of ultrafine slag powder, 5% of glass powder, and microbead fly ash particles 50%, alcohol amine compound 0.5%, defoamer 1%, air-entraining agent 0.5% and inorganic activator 8%.

[0046] The specific surface area of the above micro silica fume is 25000m 2 / Kg, loose bulk density is 400kg / m 3 , wherein the mass content of silicon dioxide is 95%; the specific surface area of the above ultrafine slag powder is 800m 2 / Kg; the fineness of the above-mentioned glass powder is 500 orders; the water demand ratio of the above-mentioned microbead fly ash particles is 90%, and the 7-day activity index is 95%; the above-mentioned defoamer is an organosilicon defoamer; the above-mentioned entrained air The agent is triterpene saponin; the above-mentioned inorganic stimulant is sulfur ash; the above-mentioned alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com