Low-viscosity and easy-pumping ultrahigh performance concrete and preparation method thereof

An ultra-high-performance concrete technology, applied in the field of building materials, can solve problems such as high viscosity, poor pumping performance, and difficult large-scale construction, and achieve the effects of high fluidity, reduced cement consumption, and reduced pumping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

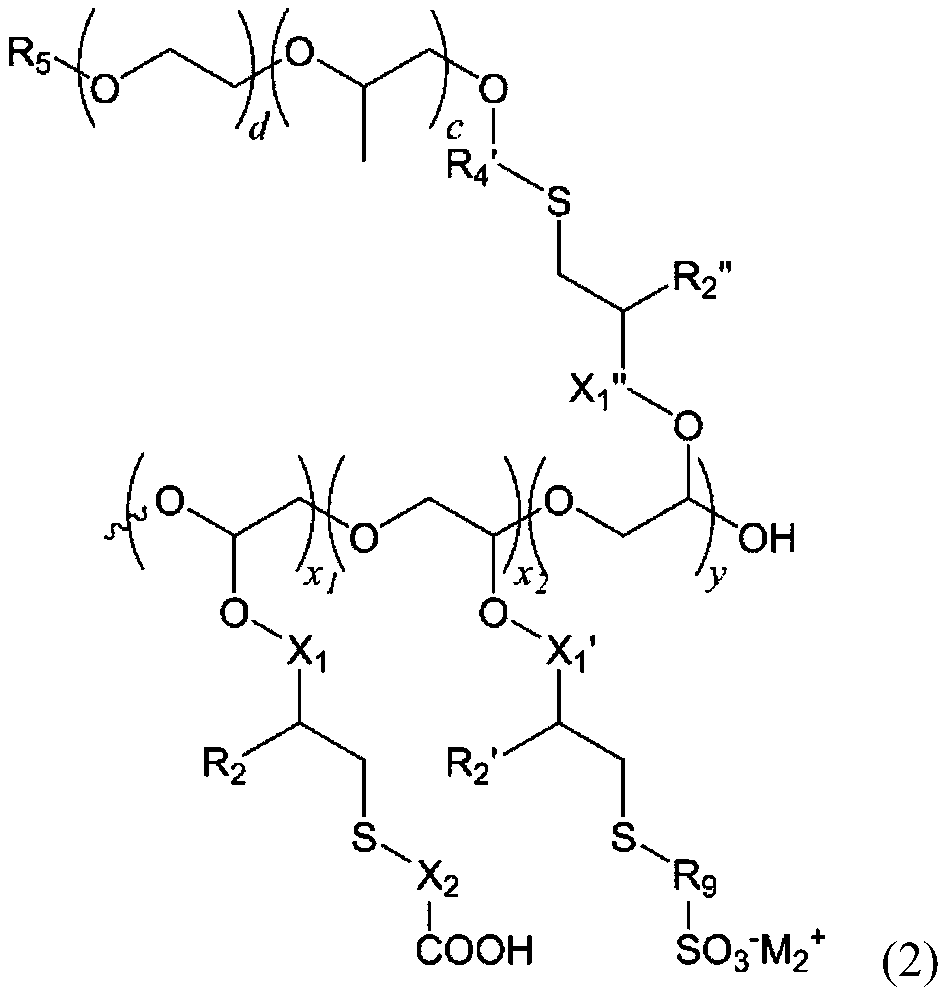

Method used

Image

Examples

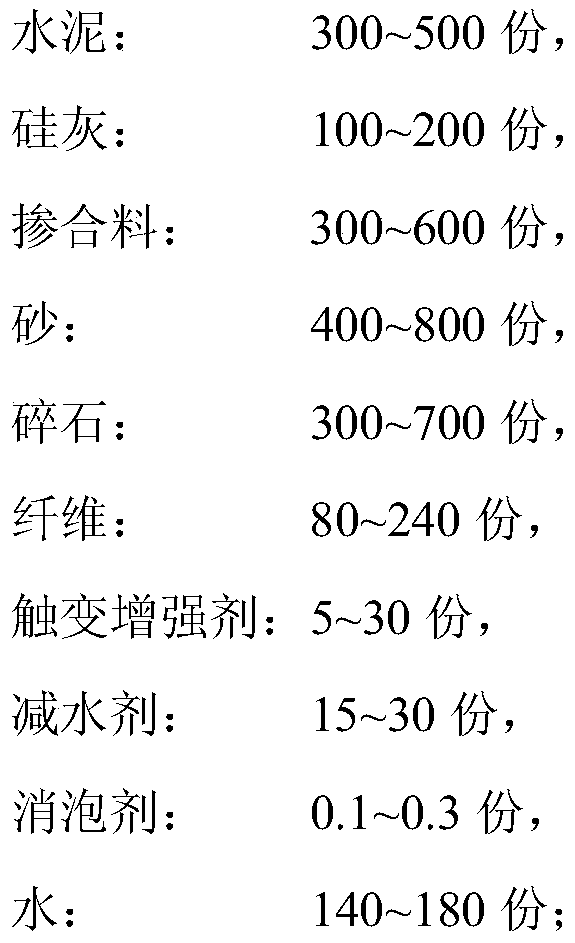

Embodiment 1

[0103] In Example 1, the admixture component is silica fume, microbeads and filler mixed in a mass ratio of 80:70:300; the filler component and the mass ratio of each component are fly ash: finely ground mineral powder: quartz powder= 80:120:100; the thixotropic enhancer is an inorganic thixotropic enhancer and an organic thixotropic enhancer mixed in a mass ratio of 10:5, and the organic thixotropic enhancer is propylene glycol alginate; the water reducer is PCE1; the fiber is Straight steel fibers and hook-end fibers are mixed in a mass ratio of 2:1.

Embodiment 2

[0104] In Example 2, the admixture component is microsilica, microbeads and filler mixed in a mass ratio of 80:70:300; the filler component and the mass ratio of each component are fly ash: finely ground mineral powder: quartz powder= 80:120:100; thixotropic enhancer is inorganic thixotropic enhancer, organic thixotropic enhancer is mixed in a mass ratio of 10:5, organic thixotropic enhancer is starch ether; water reducer is PCE2; fiber is straight Steel fibers and hook-end fibers are mixed in a mass ratio of 2:1.

Embodiment 3

[0105] In embodiment 3, the admixture component is microsilica fume, microbeads and filler mixed in a mass ratio of 100:100:250; the filler component and the mass ratio of each component are fly ash: finely ground mineral powder: quartz powder= 70:80:100; the thixotropic reinforcing agent is an inorganic thixotropic reinforcing agent; the water reducing agent is PCE3; the fiber is end-hook steel fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com