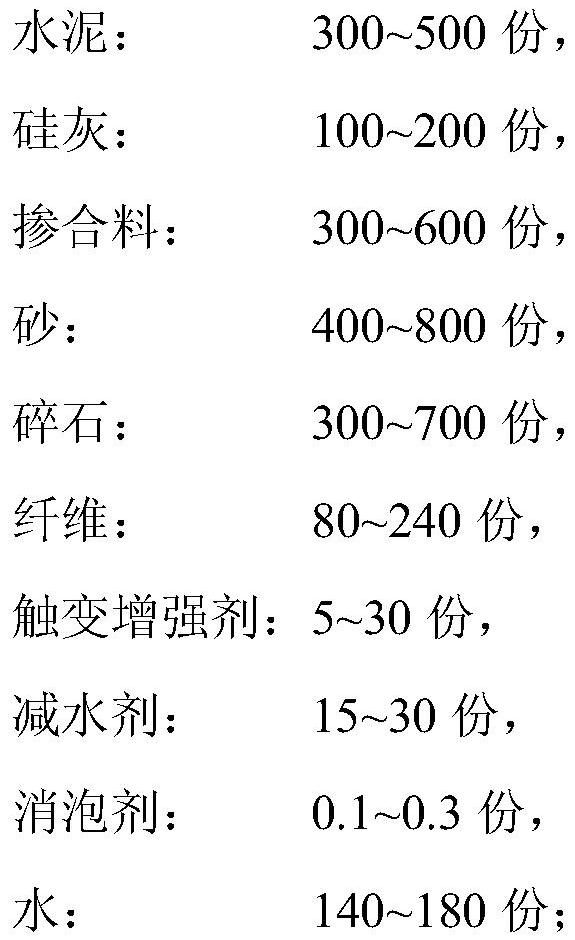

Low-viscosity, easy-to-pump ultra-high performance concrete and preparation method thereof

An ultra-high performance, concrete technology, applied in the field of building materials, can solve the problems of high viscosity, poor pumping performance, difficult to scale construction, etc., to achieve the effect of reducing viscosity, improving bulk density and reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

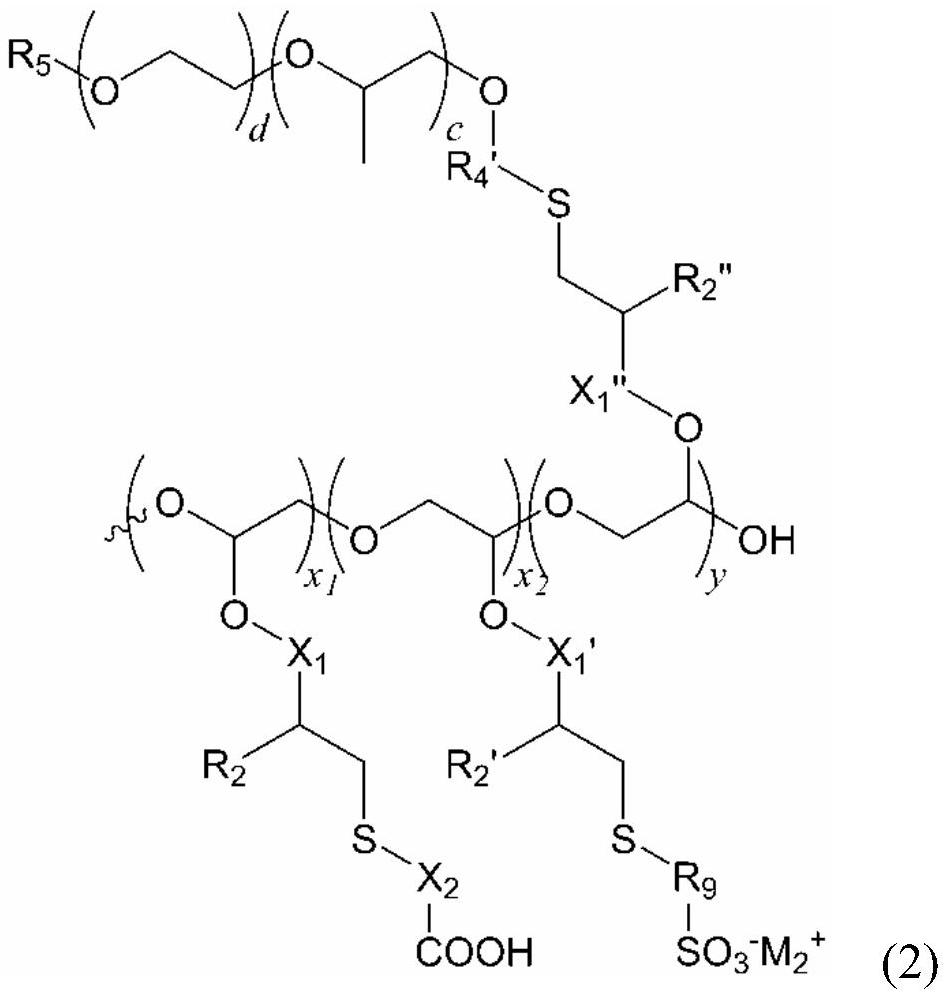

Method used

Image

Examples

Embodiment 1

[0103] In Example 1, the admixture component is silica fume, microbeads and filler mixed in a mass ratio of 80:70:300; the filler component and the mass ratio of each component are fly ash: finely ground mineral powder: quartz powder= 80:120:100; the thixotropic enhancer is an inorganic thixotropic enhancer and an organic thixotropic enhancer mixed in a mass ratio of 10:5, and the organic thixotropic enhancer is propylene glycol alginate; the water reducer is PCE1; the fiber is Straight steel fibers and hook-end fibers are mixed in a mass ratio of 2:1.

Embodiment 2

[0104] In Example 2, the admixture component is microsilica, microbeads and filler mixed in a mass ratio of 80:70:300; the filler component and the mass ratio of each component are fly ash: finely ground mineral powder: quartz powder= 80:120:100; thixotropic enhancer is inorganic thixotropic enhancer, organic thixotropic enhancer is mixed in a mass ratio of 10:5, organic thixotropic enhancer is starch ether; water reducer is PCE2; fiber is straight Steel fibers and hook-end fibers are mixed in a mass ratio of 2:1.

Embodiment 3

[0105] In embodiment 3, the admixture component is microsilica fume, microbeads and filler mixed in a mass ratio of 100:100:250; the filler component and the mass ratio of each component are fly ash: finely ground mineral powder: quartz powder= 70:80:100; the thixotropic reinforcing agent is an inorganic thixotropic reinforcing agent; the water reducing agent is PCE3; the fiber is end-hook steel fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com