Gas extraction center divided-flow type grouting and hole sealing device and hole sealing method

A technology of gas drainage and hole sealing device, which is applied in the direction of gas discharge, safety device, sealing/isolation, etc. It can solve the problems of increased gas drainage resistance, reduced sealing success rate, and affecting the sealing effect, etc., to achieve Reduce the resistance of gas extraction, improve the quality and effect, and improve the effect of tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

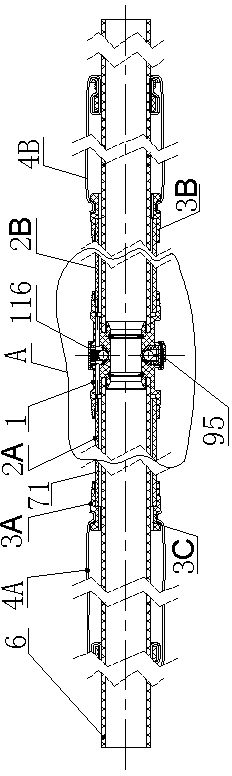

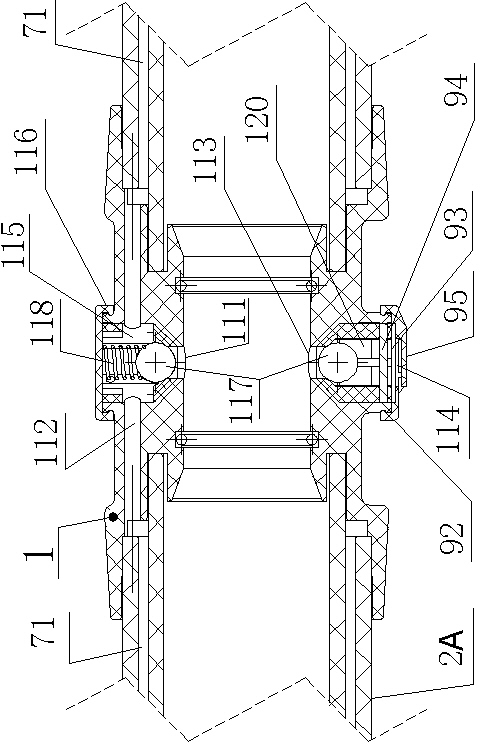

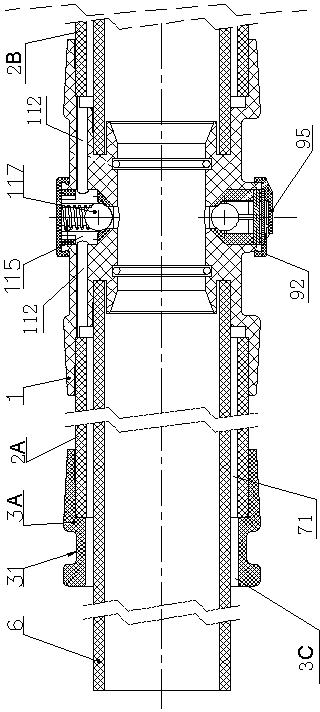

[0028] like Figure 1 to Figure 7 As shown, the gas drainage center split grouting sealing device of the present invention includes a drainage pipe 6, a grouting plug 5, a left bladder 4A and a right bladder 4B, and the drainage tube 6 connects from the left and right bladders 4A, 4B, the left and right pouches 4A and 4B have the same structure, both including inner and outer layers, the inner layer is a latex cover 4C, the outer layer is a rib cloth cover 4D, and the latex cover 4C is punctured with micropores ( not shown) for easy exhaust. The middle part of the extraction pipe 6 is provided with a multifunctional valve, the multifunctional valve includes a valve body 1, and the multifunctional valve is provided with a spring ball check valve and a film ball check valve, and the spring ball check valve is provided with a second A slurry inlet hole 111 and a first slurry outlet hole 112; a film ball check valve is provided with a second slurry inlet hole 113 and a second slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com