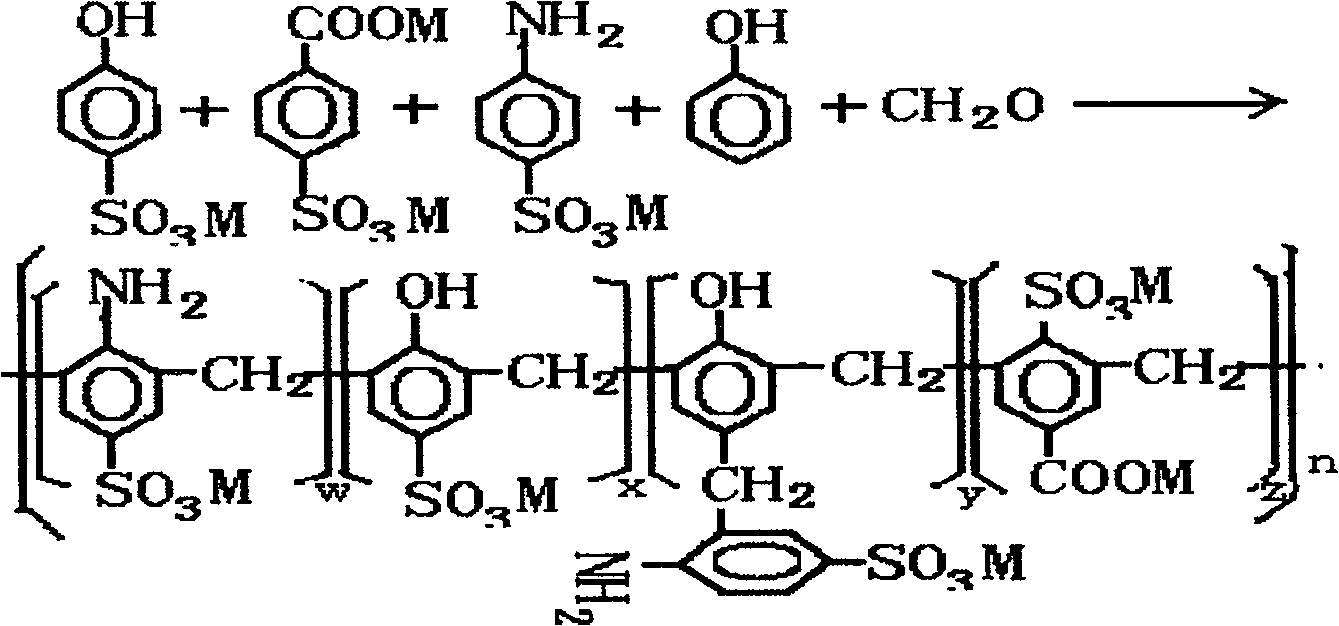

Concrete superplasticizer in amino carboxyl classes, and synthetic method

A high-efficiency water-reducing agent and concrete technology are applied in the field of ammonia carboxylate concrete high-efficiency water-reducing agent. Small slump and other problems, to achieve the effect of low cost, good workability, and no loss of slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

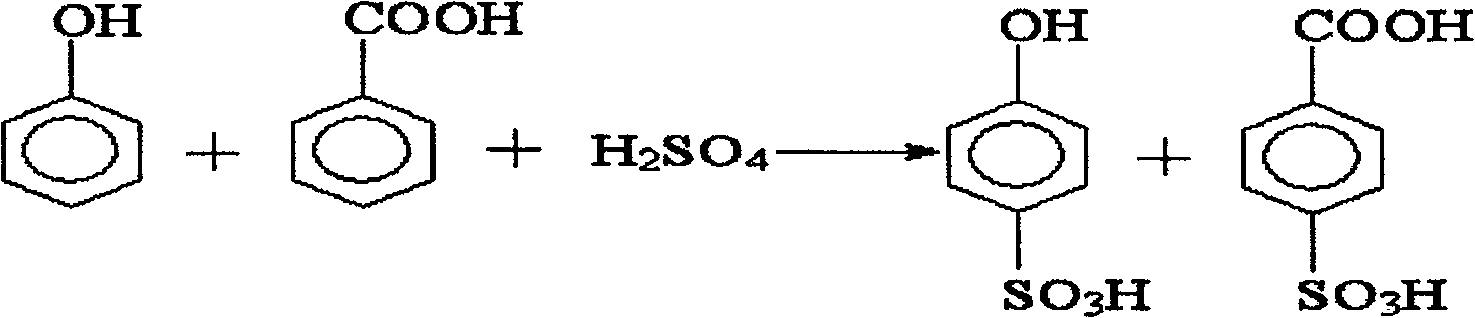

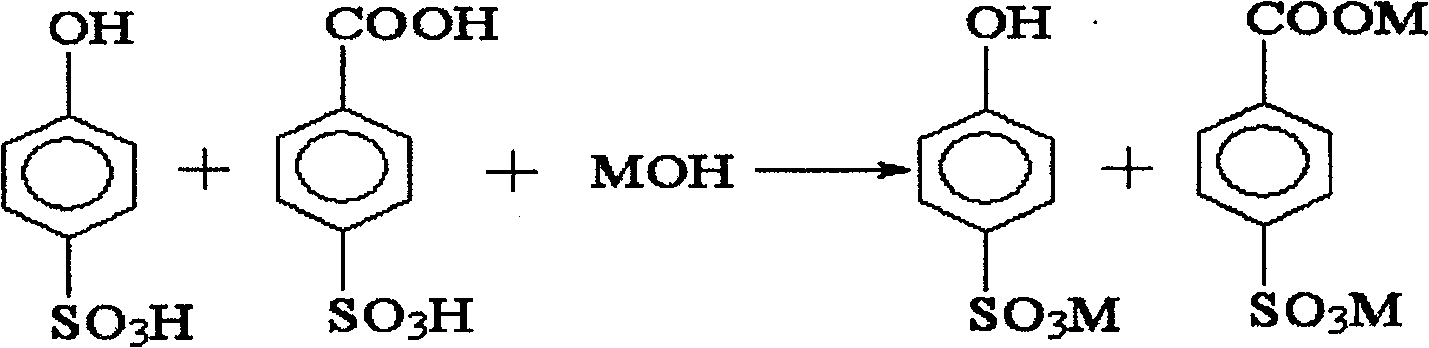

Method used

Image

Examples

Embodiment 1

[0041] Put 30g of benzoic acid, 70g of phenol and 110g of concentrated sulfuric acid into the reaction vessel, raise the temperature to 85°C, carry out sulfonation reaction for 2h, and neutralize with 30% sodium hydroxide solution to pH 7-8 to obtain the sulfonation reaction product . Add 65g of sulfonation reaction product, 50g of sodium p-aminobenzene sulfonate, 30g of phenol and 240g of water into another reaction kettle, raise the temperature to 80℃, adjust the pH to 8-9 with sodium hydroxide, stir for 15min, add dropwise at a constant speed The formaldehyde is 75g, and the dropwise addition of the formaldehyde is completed in about 2 hours, and the condensation reaction is carried out at a constant temperature of 80°C for 6 hours to obtain the new type of ammonia carboxylate concrete superplasticizer of the present invention.

Embodiment 2

[0043]Put 40g of benzoic acid, 60g of phenol and 110g of concentrated sulfuric acid into the reaction vessel, heat to 85°C, carry out sulfonation reaction for 2h, and neutralize with 30% sodium hydroxide solution to pH 7-8 to obtain the sulfonation reaction product . Add 70g of sulfonation reaction product, 42g of sodium p-aminobenzene sulfonate, 30g of phenol and 240g of water into another reaction kettle. The temperature is raised to 85°C, the pH is adjusted to 8-9 with sodium hydroxide, stirred for 15min, and added dropwise at a constant speed. The formaldehyde is 72g, the formaldehyde is added dropwise in about 2 hours, and the condensation reaction is carried out at a constant temperature of 85°C for 6 hours to obtain the new type of ammonia carboxyl concrete superplasticizer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com