A kind of glue reducer for concrete and preparation method thereof

A glue reducer and concrete technology, which is applied in the field of concrete glue reducer and its preparation, can solve the problems of large air-entrainment, inability to handle concrete, and large fluctuations in concrete strength, so as to achieve reduced bleeding, guaranteed strength, and high porosity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A kind of preparation method of glue reducer for concrete, this preparation method has following preparation steps:

[0016] (1) Prepare the following formula components in terms of mass percentage: 35% mixed alcohol amine, 12% mixed alcohol, 10% melamine superplasticizer, 3.5% catalyst, and the balance is water;

[0017] (2) Add mixed alcohol amine, mixed alcohol, 2% by mass catalyst, and 65-80% by mass water into the reaction vessel in order, stir well, keep warm at 60°C for 1 hour, then add melamine for efficient water reduction agent and the remaining mass parts of the catalyst, continue to keep warm and stir for 0.5h, and finally add 20-35% water to dilute to obtain the finished product of glue reducer for concrete.

Embodiment 2

[0019] A kind of preparation method of glue reducer for concrete, this preparation method has following preparation steps:

[0020] (1) Prepare the following formula components in terms of mass percentage: 25% mixed alcohol amine, 20% mixed alcohol, 5% melamine superplasticizer, 2% catalyst, and the balance is water;

[0021] Step (2) is the same as the first embodiment.

Embodiment 3

[0023] A kind of preparation method of glue reducer for concrete, this preparation method has following preparation steps:

[0024] (1) Prepare the following formula components in terms of mass percentage: 45% mixed alcohol amine, 5% mixed alcohol, 15% melamine superplasticizer, 5% catalyst, and the balance is water;

[0025] Step (2) is the same as the first embodiment.

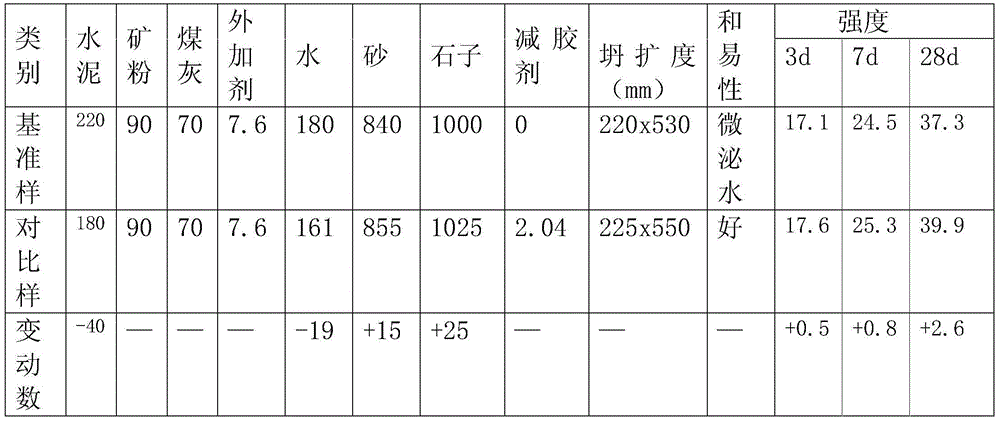

[0026] Apply the adhesive reducer obtained in the above-mentioned Examples 1 to 3 to the adhesive reducer experiment of the comparative sample in the table below, and the results are as follows: C30 concrete (unit: kg)

[0027]

[0028] It can be seen from the above table that the adhesive reducer of the present invention can improve the service performance of concrete while reducing the amount of cement by 10% to 20%. It is a high-tech energy-saving and environmentally friendly product that meets the requirements of green high-performance concrete. The concept of green high performance concrete (GHPC) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com