C60 pumping concrete and preparation method thereof

A technology for pumping concrete and machine-made sand, which is applied in the field of concrete, and can solve the problems of reducing the encapsulation of cementitious materials on aggregates, affecting the compressive strength of concrete, reducing the workability of concrete, etc., and achieving improved encapsulation and good encapsulation , Improve the effect of particle shape difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

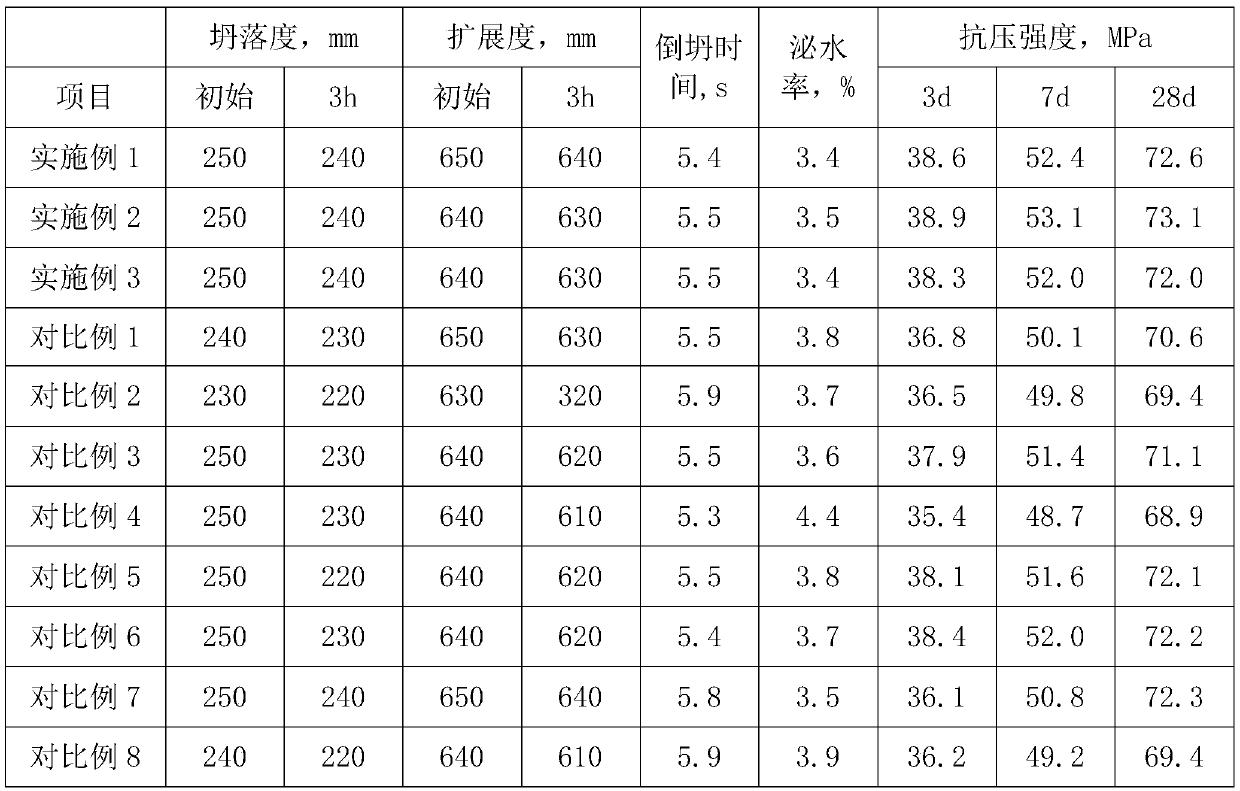

Examples

preparation example 1

[0038] Preparation example 1 of slump-retaining agent: ①Take 160kg of isopentenol polyoxyethylene ether, 20kg of 1,4-butanediol vinyl ether and 200kg of water, heat it to 60°C, and keep stirring for 10 minutes to obtain the mixture A;

[0039] ② Take 4kg of acrylic acid, 20kg of hydroxyethyl acrylate and 50kg of an aqueous solution of 1wt% sodium persulfate, and mix them uniformly to obtain a mixed solution B;

[0040] ③Add 2kg of thioglycolic acid, 0.5kg of sodium methacrylate hydroxypropyl sulfonate, 0.5kg of ethylene glycol dimethacrylate and 0.3kg of sodium isopropylxanthate to the mixture A, and keep it warm at 60°C After stirring for 5 minutes, add 50kg of 1wt% sodium persulfate aqueous solution dropwise while stirring, and the dropwise addition is completed within 30 minutes; agent mother liquor;

[0041] ④Add 20wt% aqueous solution of sodium hydroxide to the mother liquor of the slump-preserving agent, adjust the pH to 6, and obtain the slump-retaining agent with a so...

preparation example 2

[0042] Preparation example 2 of slump-retaining agent: ①Take 170kg of prenol polyoxyethylene ether, 25kg of 1,4-butanediol vinyl ether and 250kg of water, heat it to 65°C, and keep stirring for 15 minutes to obtain the mixed solution A;

[0043] ② Take 5kg of acrylic acid, 22.5kg of hydroxyethyl acrylate and 55kg of an aqueous solution of 1wt% sodium persulfate, and mix them uniformly to obtain a mixed solution B;

[0044] ③Add 3kg of thioglycolic acid, 0.75kg of sodium methacrylate hydroxypropyl sulfonate, 0.75kg of ethylene glycol dimethacrylate and 0.4kg of sodium isopropylxanthate to the mixture A, and keep it warm at 65°C After stirring for 7.5min, add dropwise an aqueous solution of 55kg of 1wt% sodium persulfate while stirring, and complete the dropwise addition within 30min; Slump retaining agent mother liquor;

[0045] ④Add 20wt% sodium hydroxide aqueous solution to the slump retaining agent mother liquor, adjust the pH to 6.5, and obtain a slump retaining agent with...

preparation example 3

[0046] Preparation example 3 of slump-retaining agent: ①Take 180kg of isopentenol polyoxyethylene ether, 30kg of 1,4-butanediol vinyl ether and 300kg of water, heat it to 70°C, keep stirring for 20min, and obtain the mixture A;

[0047] ② Take 6kg of acrylic acid, 25kg of hydroxyethyl acrylate and 60kg of an aqueous solution of 1wt% sodium persulfate, and mix them uniformly to obtain a mixed solution B;

[0048] ③Add 4kg of thioglycolic acid, 1kg of sodium methacrylate hydroxypropyl sulfonate, 1kg of ethylene glycol dimethacrylate and 0.5kg of sodium isopropylxanthate to the mixture A, and keep stirring at 70°C for 10 minutes Finally, dropwise add 60 kg of 1wt% sodium persulfate aqueous solution while stirring, and finish the dropwise addition within 30 minutes; then finish adding the mixed solution B dropwise while stirring, finish the dropwise addition within 1 hour, continue the heat preservation reaction for 1.5 hours, and obtain the slump retaining agent Mother liquor;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com