Novel lubricant for concrete pumping pipelines

A technology for concrete pumps and lubricants, applied in lubricating compositions, petroleum industry, etc., can solve the problems of reducing concrete strength, high cost, and manpower consumption, and achieve the effects of reducing pumping resistance, reducing dosage, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

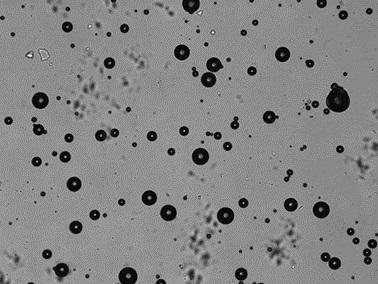

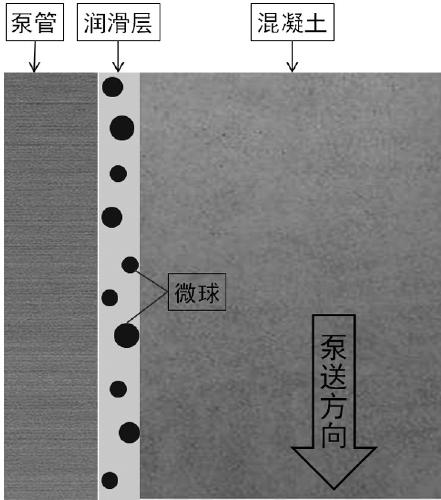

[0018] Lubricants were formulated in the following percentages by weight: polyacrylamide 8%; hydroxypropyl methylcellulose 6%; sodium sulfate 50%; glass microspheres 36%. Among them, the molecular weight of polyacrylamide is 18 million, and the particle size range of glass microspheres is 10-20 μm. The above-mentioned raw materials are weighed in parts by weight and then stirred evenly. Prepare the lubricant solution according to the mass ratio of lubricant: water = 1:99. During the preparation process, the lubricant should be slowly added to the water while stirring continuously until the lubricant is completely dissolved to obtain a lubricant solution with a mass fraction of 1%. The dissolution time was determined to be 4 minutes, and the viscosity of the lubricant solution was 68 mPa·s.

Embodiment 2

[0020] Lubricants were formulated in the following percentages by weight: polyacrylamide 8%; carboxymethyl cellulose 2%; sodium sulfate 30%; glass microspheres 60%. Among them, the molecular weight of polyacrylamide is 16 million, and the particle size range of glass microspheres is 10-20 μm. The above-mentioned raw materials are weighed in parts by weight and then stirred evenly. Prepare the lubricant solution according to the mass ratio of lubricant: water = 1:99. During the preparation process, the lubricant should be slowly added to the water while stirring continuously until the lubricant is completely dissolved to obtain a lubricant solution with a mass fraction of 1%. It was measured that the dissolution time was 5 min, and the solution viscosity was 52 mPa·s.

Embodiment 3

[0022] Lubricants were formulated in the following percentages by weight: polyacrylamide 4%; hydroxypropyl methylcellulose 6%; ammonium sulfate 40%; glass microspheres 50%. Among them, the molecular weight of polyacrylamide is 15 million, and the particle size range of glass microspheres is 10-20 μm. The above-mentioned raw materials are weighed in parts by weight and then stirred evenly. Prepare the lubricant solution according to the mass ratio of lubricant: water = 1:99. During the preparation process, the lubricant should be slowly added to the water while stirring continuously until the lubricant is completely dissolved to obtain a lubricant solution with a mass fraction of 1%. It was measured that the dissolution time was 4min, and the solution viscosity was 45mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com