Method for synthesizing universal polycarboxylic water reducer

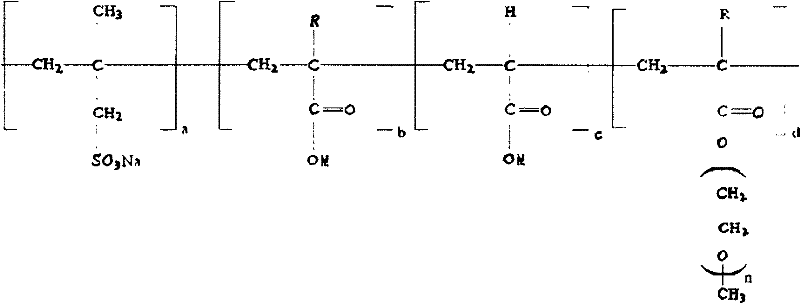

A type of polycarboxylic acid and water reducing agent technology, applied in the field of polycarboxylic acid high-performance concrete water reducing agent and its preparation, can solve the problems of low water reduction rate and poor slump retention, and achieve improved carbonization resistance and frost resistance. The effect of improving fusion ability and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

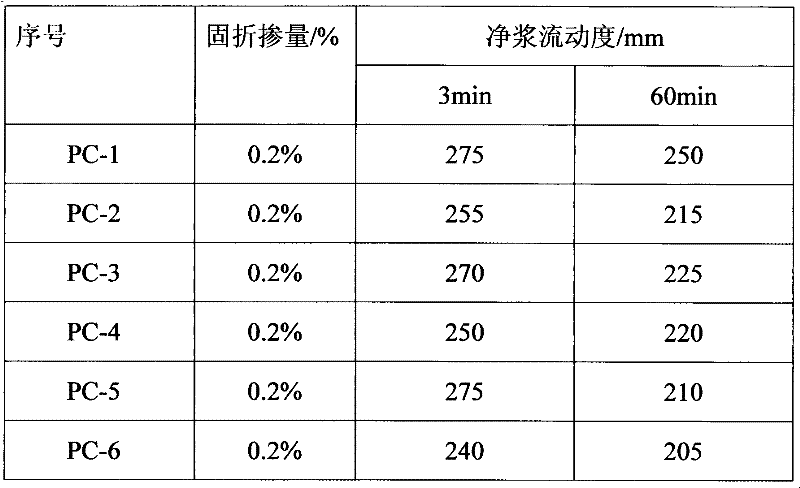

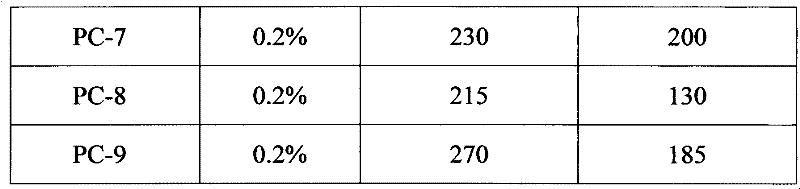

Examples

Embodiment 1

[0017] best ratio

[0018] Put 120.00 parts of polyoxyethylene ether with a molecular weight of 2400 and 97.05 parts of water into a reaction container, raise the temperature, and stir at a temperature of 65±5°C to completely dissolve the reactants, then add 14.4 parts of acrylic acid dissolved in the container dropwise + 6.3 parts of sodium methacryl sulfonate + 40 parts of aqueous solution of water and 60.00 parts of 5% ammonium persulfate solution and 10.00 parts of mercaptopropionic acid in a solution of 10% by mass, control the rate of addition, and drop it in 100 ± 10 minutes , keep the temperature at 65±5°C, and continue the reaction for 4 hours. After cooling, add about 4 parts of 40% sodium hydroxide solution to adjust the pH=6.5±0.5 to obtain the 40% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 2

[0020] Put 120.00 parts of polyoxyethylene ether with a molecular weight of 2400 and 81.85 parts of water into a reaction container, raise the temperature, and stir at a temperature of 65±5°C to completely dissolve the reactants, then add 3.6 parts of acrylic acid dissolved in the container dropwise + 6.3 parts of sodium methacryl sulfonate + 40 parts of aqueous solution of water and 60.00 parts of 5% ammonium persulfate solution and 10.00 parts of mercaptopropionic acid in a solution of 10% by mass, control the rate of addition, and drop it in 100 ± 10 minutes , keep the temperature at 65±5°C, and continue the reaction for 4 hours. After cooling, add about 4 parts of 40% sodium hydroxide solution to adjust the pH=6.5±0.5 to obtain the 40% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 3

[0022] Put 120.00 parts of polyoxyethylene ether with a molecular weight of 2400 and 102.45 parts of water into a reaction container, raise the temperature, and stir at a temperature of 65±5°C to completely dissolve the reactants, then add 18 parts of acrylic acid dissolved in the container dropwise + 6.3 parts of sodium methacryl sulfonate + 40 parts of aqueous solution of water and 60.00 parts of 5% ammonium persulfate solution and 10.00 parts of mercaptopropionic acid in a solution of 10% by mass, control the rate of addition, and drop it in 100 ± 10 minutes , keep the temperature at 65±5°C, and continue the reaction for 4 hours. After cooling, add about 4 parts of 40% sodium hydroxide solution to adjust the pH=6.5±0.5 to obtain the 40% polycarboxylate high-performance concrete water reducer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com