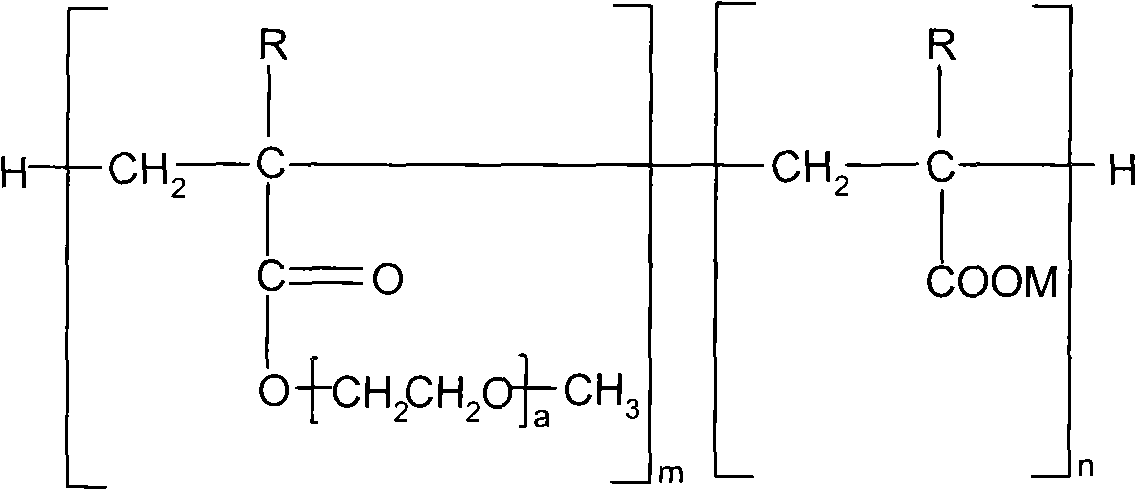

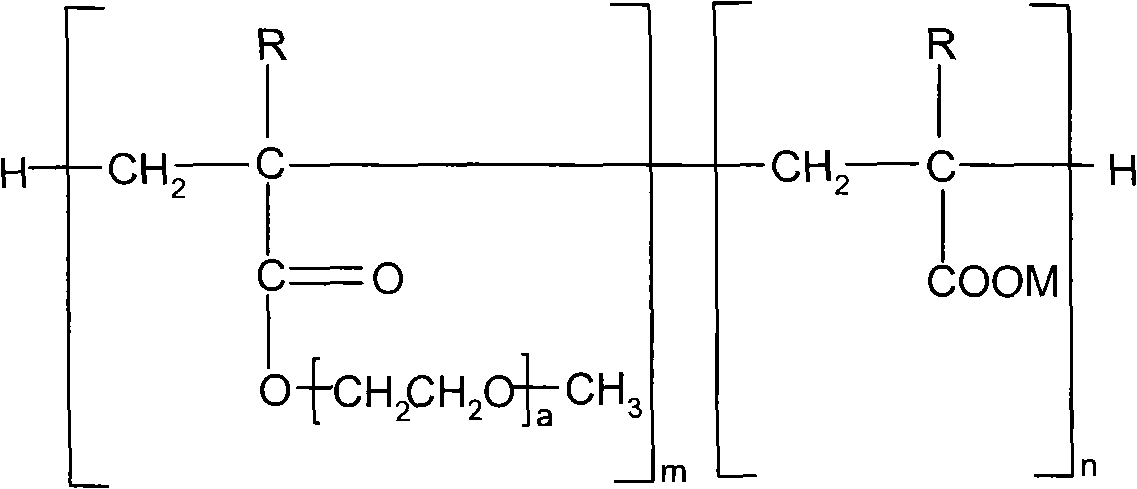

Preparation method of ultra-low hydration heat polycarboxylate-based water reducing agent

A technology of thermal polycarboxylic acid and water reducing agent, which is applied in the field of preparation of ultra-low hydration heat polycarboxylic acid series water reducing agent, can solve the problems of single performance of the water reducing agent, and achieves good appearance quality and improved compressive strength. , the effect of small color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

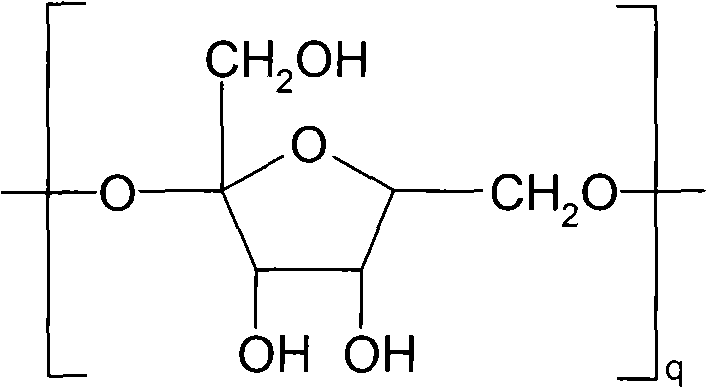

Embodiment 1

[0026] Add 16.67g of water into the reactor, heat up, and dropwise add 10.3g of methacrylic acid, 8.0g of polyethylene glycol monomethyl ether methacrylate (molecular weight 500) and 20.95g of water at a temperature of 80 to 90°C. Composed solution (weigh methacrylic acid and polyethylene glycol monomethyl ether methacrylate, and then dissolve in water to obtain), the other side drops initiator and modifier solution (0.73g azobisisobutyl Nitrile, 0.05g ferrous sulfate, 0.45g polyhydric alcohol (q=1) and 38.01g water are mixed), control the dropping speed, finish dropping in 6-7h, and keep warm at 90-95°C for 4-5h. Cool to room temperature, adjust pH=7~8 with sodium hydroxide, obtain the ultra-low heat of hydration polycarboxylate water-reducer of the present invention (the carboxyl group grafted on the main chain and the mole of polyoxyethylene group) of the present invention The ratio is about 7:1).

Embodiment 2

[0028] Add 16.67g of water into the reactor, heat up, and dropwise add 10.8g of methacrylic acid, 15.5g of polyethylene glycol monomethyl ether methacrylate (molecular weight 400) and 33.75g of water at a temperature of 80±5°C. formed solution, the other side was added dropwise initiator and modifier solution (1.05g azobisisobutyronitrile, 0.107g ferrous sulfate, 0.85g polyhydric alcohol (q=4) and 57.92g water), and the rate of addition was controlled. After 6-7 hours of dripping, keep warm at 90-95°C for 4-5 hours. Cool to room temperature, adjust pH=7~8 with sodium hydroxide, obtain the ultra-low heat of hydration polycarboxylate water-reducer of the present invention (the carboxyl group grafted on the main chain and the mole of polyoxyethylene group) of the present invention The ratio is about 3:1).

Embodiment 3

[0030] Add 16.67g of water into the reactor, heat up, and dropwise add 8.2g of methacrylic acid, 26.1g of polyethylene glycol monomethyl ether methacrylate (molecular weight 300) and 46.55g of water at a temperature of 80±5°C. formed solution, the other side was added dropwise initiator and modifier solution (1.37g azobisisobutyronitrile, 0.152g ferrous sulfate, 1.35g polyhydric alcohol (q=10) and 77.95g water), control the rate of addition, After 6-7 hours of dripping, keep warm at 90-95°C for 4-5 hours. Cool to room temperature, adjust pH=7~8 with sodium hydroxide, obtain the ultra-low heat of hydration polycarboxylate water-reducer of the present invention (the carboxyl group grafted on the main chain and the mole of polyoxyethylene group) of the present invention The ratio is about 1:1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com